Monocrystal diamond tool processing method and monocrystal diamond tool

A technology of single crystal diamond and processing method, which is applied in the direction of metal processing equipment, cutting tools for lathes, manufacturing tools, etc., which can solve the problem of demanding precision and quality of diamond cutting tools, severe impact on the surface and edge of cutting tools, and limiting the quality of cutting tools, etc. problems, to avoid surface impact groove marks, improve efficiency and quality, and reduce polishing allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

[0037] A single crystal diamond tool and a tool processing method, comprising the following steps:

[0038] 1) Prepare single crystal diamond material;

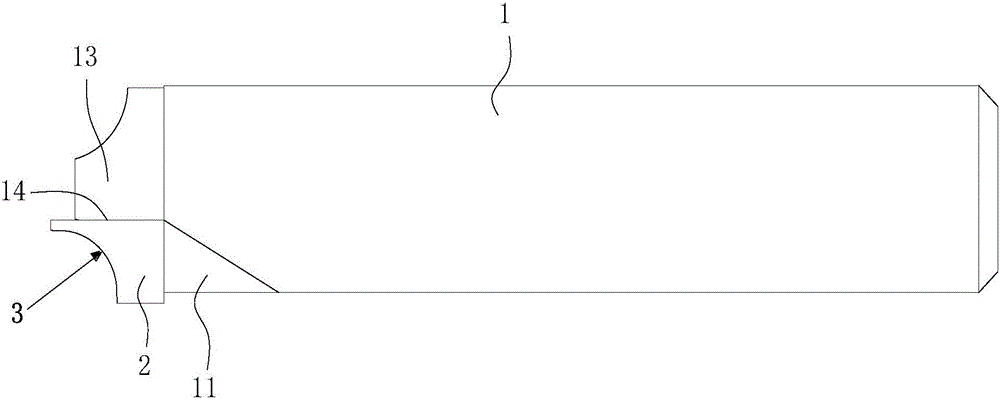

[0039] 2) Machining the end of the cemented carbide substrate 1 to facilitate the positioning and welding of the single crystal diamond material;

[0040] 3) Weld the single crystal diamond material on the end of the cemented carbide substrate 1 to form a single crystal diamond tool 2, so that the axial angle 5 and the radial angle 4 of the single crystal diamond tool 2 are both positive, and the range of the axial angle 5 is 3 to 7°, and the radial angle 4 ranges from 0 to 2°;

[0041] 4) According to the design requirements of the tool outline, the single crystal diamond tool 2 is processed by the laser cutting method, so that it has a first flank 21, a second flank 22 and a tool edge 3, and the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com