Surface polylysine modifying method for PDMS micro-fluidic chip

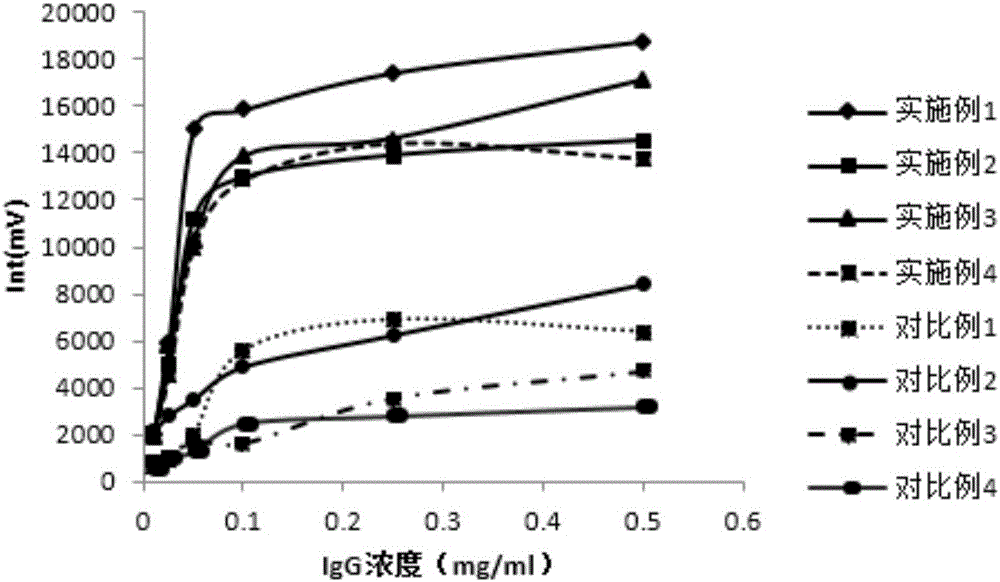

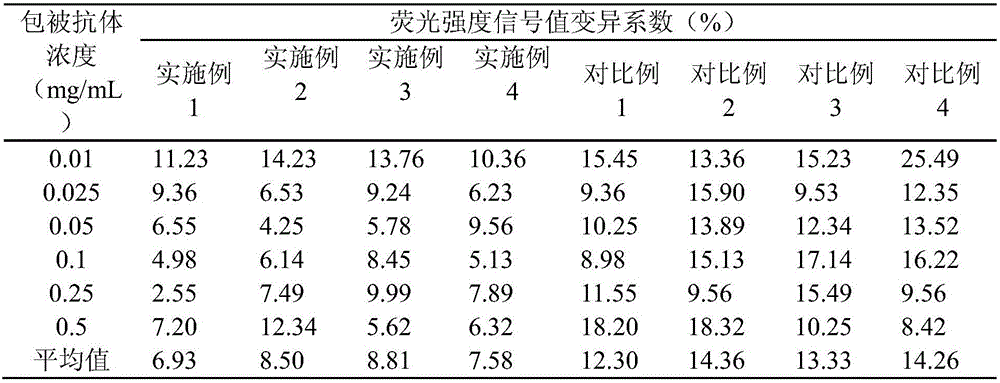

A microfluidic chip and polylysine technology, applied in the field of microfluidics, can solve the problems of poor sensitivity of the chip substrate, weak dynamic binding, low signal detection value, etc., to achieve the solution of weak binding, The effect of low coefficient of variation between points and high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

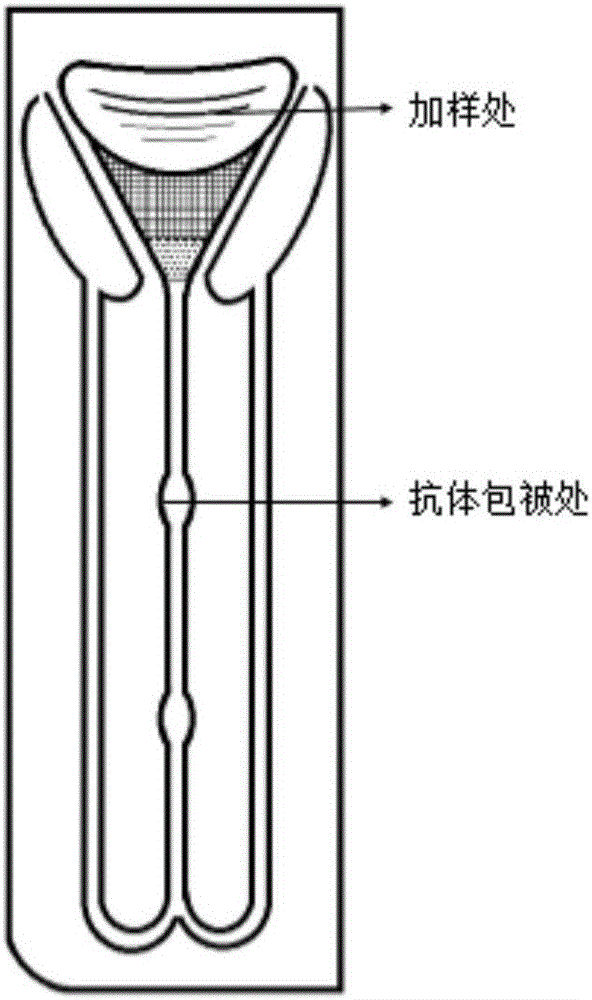

[0038] In this embodiment, the poly-lysine modification on the surface of the PDMS microfluidic chip is carried out by the following method, which specifically includes the following steps:

[0039] (1) The PDMS microfluidic chip is ultrasonically cleaned with deionized water, and then treated with plasma for 10 minutes, the plasma generation power is 10kw, and the plasma air flow rate is 200mL / min to obtain the PDMS microfluidic after plasma activation. control chip;

[0040] (2) Place the PDMS microfluidic chip after the plasma activation treatment in an APTMS solution with a concentration of 1%, and treat it at 65° C. for 60 minutes to obtain a silanized PDMS microfluidic chip, dry it with nitrogen, and wash it with water. Then dry it with nitrogen gas and set aside.

[0041] (3) The silanized PDMS microfluidic chip is placed in a polylysine solution, and covalently bonded under the action of a cross-linking agent. The amount of the cross-linking agent is such that its con...

Embodiment 2

[0043] In this embodiment, the poly-lysine modification on the surface of the PDMS microfluidic chip is carried out by the following method, which specifically includes the following steps:

[0044] (1) The PDMS microfluidic chip is ultrasonically cleaned with deionized water, and then treated with plasma for 3 minutes, the plasma generation power is 20kw, and the plasma air flow rate is 250mL / min to obtain the PDMS microfluidic after plasma activation. control chip;

[0045] (2) Place the PDMS microfluidic chip after the plasma activation treatment in an APTMS solution with a concentration of 2%, and treat it at 60° C. for 45 minutes to obtain a silanized PDMS microfluidic chip, dry it with nitrogen, and wash it with water. Then dry it with nitrogen gas and set aside.

[0046] (3) The silanized PDMS microfluidic chip is placed in a polylysine solution, and covalently bonded under the action of a cross-linking agent. The amount of the cross-linking agent is such that its conc...

Embodiment 3

[0048] In this embodiment, the poly-lysine modification on the surface of the PDMS microfluidic chip is carried out by the following method, which specifically includes the following steps:

[0049] (1) The PDMS microfluidic chip is ultrasonically cleaned with deionized water, and then treated with plasma for 15 minutes, the plasma generation power is 15kw, and the plasma air flow rate is 200mL / min to obtain the PDMS microfluidic after plasma activation. control chip;

[0050] (2) Place the PDMS microfluidic chip after the plasma activation treatment in an APTMS solution with a concentration of 5%, and treat it at 50° C. for 90 minutes to obtain a silanized PDMS microfluidic chip, dry it with nitrogen, and wash it with water. Then dry it with nitrogen gas and set aside.

[0051] (3) The silanized PDMS microfluidic chip is placed in a polylysine solution, and covalently bonded under the action of a cross-linking agent. The amount of the cross-linking agent is such that its con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com