Toluene and methanol and/or dimethyl ether alkylation reaction catalyst and preparation method thereof

A technology of dimethyl ether alkanes and catalysts, which is applied in the field of catalysts for the alkylation reaction of toluene and methanol or/and dimethyl ether and its preparation, can solve the problems of weak acid center strength and reduced toluene conversion rate, and reduce light The generation of hydrocarbons, the improvement of toluene conversion rate, and the effect of inhibiting the disproportionation reaction of toluene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

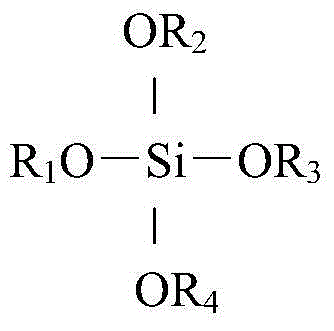

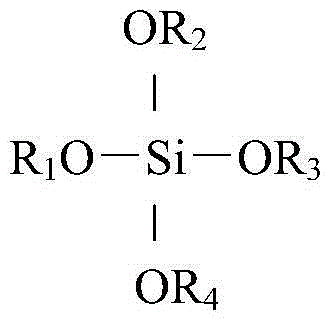

Method used

Image

Examples

Embodiment 1

[0039] Catalyst preparation

[0040] (1) 200gHZSM-5 zeolite molecular sieve (SiO 2 / Al 2 o 3 =100) (Nankai University Catalyst Factory) was added into 300 g concentration of 8% phosphoric acid aqueous solution, soaked at normal temperature for about 6 hours. Then the solid sample was centrifuged, dried in an air atmosphere at 120°C for 12 hours, and calcined in an air atmosphere at 550°C for 4 hours.

[0041] (2) Add the impregnated phosphorus sample in step (1) into 300 g of lanthanum nitrate aqueous solution with a concentration of 8 wt%, and immerse at room temperature for about 6 hours. Then the solid sample was centrifuged, dried in an air atmosphere at 120°C for 12 hours, and calcined in an air atmosphere at 550°C for 4 hours.

[0042] (3) Cool the roasted sample in step (2) to 150° C. and then move it into a desiccator to continue cooling to room temperature. Move the sample down to room temperature into a desiccator filled with deionized water at the bottom, and the...

Embodiment 2

[0046] Catalyst preparation

[0047] (3) 200gHZSM-5 zeolite molecular sieve (SiO 2 / Al 2 o 3 =150) (Nankai University Catalyst Factory) was added into 300 g concentration of 5% phosphoric acid aqueous solution, soaked at normal temperature for about 6 hours. Then the solid sample was centrifuged, dried in an air atmosphere at 120°C for 24 hours, and calcined in an air atmosphere at 550°C for 8 hours.

[0048] (4) Add the impregnated phosphorus sample in step (1) into 300 g of 5 wt % lanthanum nitrate aqueous solution, and immerse at room temperature for about 6 hours. Then the solid sample was centrifuged, dried in an air atmosphere at 120°C for 24 hours, and calcined in an air atmosphere at 550°C for 6 hours.

[0049] (6) Cool the roasted sample in step (2) to 150° C. and then move it into a desiccator to continue cooling to room temperature. Move the sample down to room temperature into a desiccator filled with deionized water at the bottom, and then put the desiccator ...

Embodiment 3

[0053] Response evaluation

[0054] The catalysts HCTM-01 and HCTM-02 prepared in Examples 1 and 2 were pressed into tablets, crushed and sieved to 40-60 meshes. 10 g of catalysts were loaded into the reactor respectively, treated in a nitrogen atmosphere at 550°C for 1 hour, and then cooled to a reaction temperature of 480°C. Pump toluene and methanol into the reactor through the feed pump to contact with the catalyst for reaction, the mass space velocity of toluene feed is 2h -1 , the feed molecular ratio of toluene to methanol was 2 / 1, and the reaction products were analyzed online by gas chromatography, and the composition of non-aqueous products was shown in Table 1.

[0055] Table 1

[0056] catalyst

[0057] *wt%, product mass distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com