Preparation method of sodium ion battery high capacity graphite negative electrode material

A sodium-ion battery, graphite negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems affecting the first efficiency and cycle performance, increase, etc., to increase the amount of insertion, increase the specific capacity, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

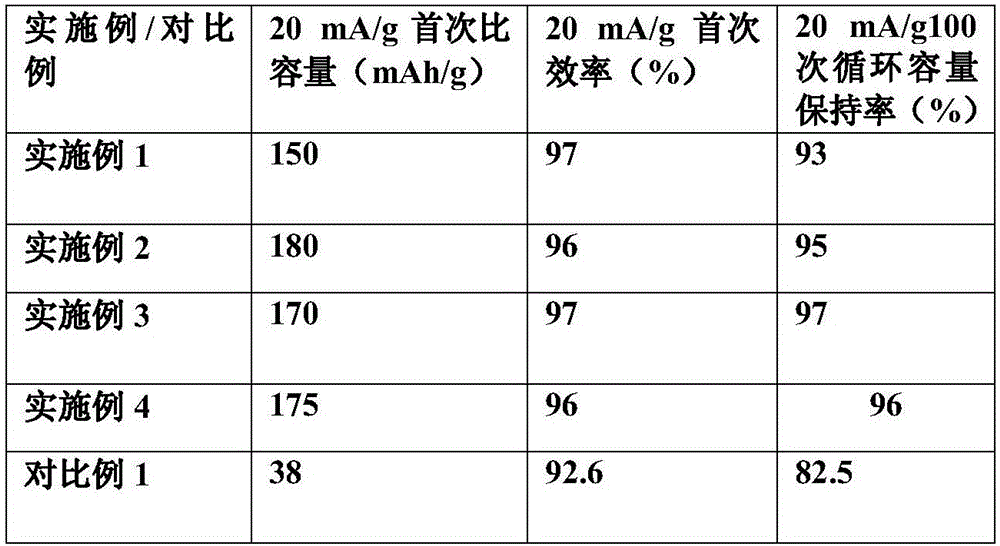

Examples

Embodiment 1

[0017] A method for preparing a high-capacity graphite negative electrode material for a sodium ion battery, comprising the steps of:

[0018] (1) Slowly add a certain amount of graphite into sulfuric acid with a concentration of 20%, then add the oxidant and titanium source in turn, stir and react in a constant temperature water bath at 20°C for 4h, after the reaction is completed, wash with water until the pH reaches 6.0, and filter at 100 Dry at °C to obtain titanium-intercalated graphite; the graphite is natural graphite, the particle size D50=10um, the purity is 99.9%, the oxidizing agent is potassium dichromate; the titanium source is n-butyl titanate.

[0019] (2) Put the titanium-intercalated graphite obtained in step (1) in an atmosphere furnace at 1000° C. for 4 hours of high-temperature treatment to obtain a high-capacity graphite negative electrode material for a sodium-ion battery. The mass ratio of each raw material is graphite:sulfuric acid:oxidant:titanium sour...

Embodiment 2

[0021] A method for preparing a high-capacity graphite negative electrode material for a sodium ion battery, comprising the steps of:

[0022] (1) Slowly add a certain amount of graphite into sulfuric acid with a concentration of 80%, then add oxidant and titanium source in turn, stir and react in a constant temperature water bath at 70°C for 0.5h, after the reaction is completed, wash with water until the pH reaches 7.0, filter and place Dry at 80°C to obtain titanium-intercalated graphite; the graphite is natural graphite, particle size D50=20um, purity 99.9%, oxidant potassium permanganate; titanium source is tetrabutyl titanate.

[0023] (2) Put the titanium-intercalated graphite obtained in step (1) in an atmosphere furnace at 800° C. for 8 hours of high-temperature treatment to obtain a high-capacity graphite negative electrode material for a sodium-ion battery. The mass ratio of each raw material is graphite:sulfuric acid:oxidant:titanium source=1:5:0.1:0.1; the protect...

Embodiment 3

[0025] A method for preparing a high-capacity graphite negative electrode material for a sodium ion battery, comprising the steps of:

[0026] (1) Slowly add a certain amount of graphite into sulfuric acid with a concentration of 60%, then add oxidizing agent and titanium source in turn, stir and react in a constant temperature water bath at 50°C for 3h, after the reaction is completed, wash with water until the pH reaches 6.5, and filter at 90°C Dry at °C to obtain titanium-intercalated graphite; the graphite is artificial graphite, the particle size D50=15um, the purity is 99.9%, the oxidizing agent is hydrogen peroxide; the titanium source is titanium tetrachloride.

[0027] (2) Put the titanium-intercalated graphite obtained in step (1) in an atmosphere furnace at 500° C. for 10 hours of high-temperature treatment to obtain a high-capacity graphite negative electrode material for a sodium-ion battery. The mass ratio of each raw material is graphite:sulfuric acid:oxidant:ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com