A kind of preparation method of novel solar cell

A solar cell, a new type of technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reducing the conversion efficiency of solar cells, and achieve the effects of good surface morphology, cost reduction, and good photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

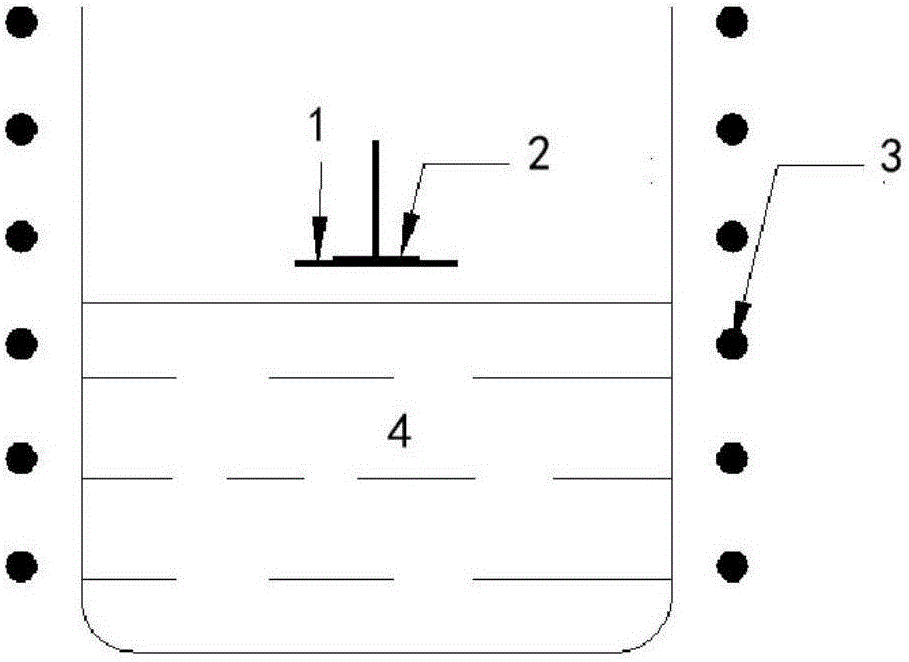

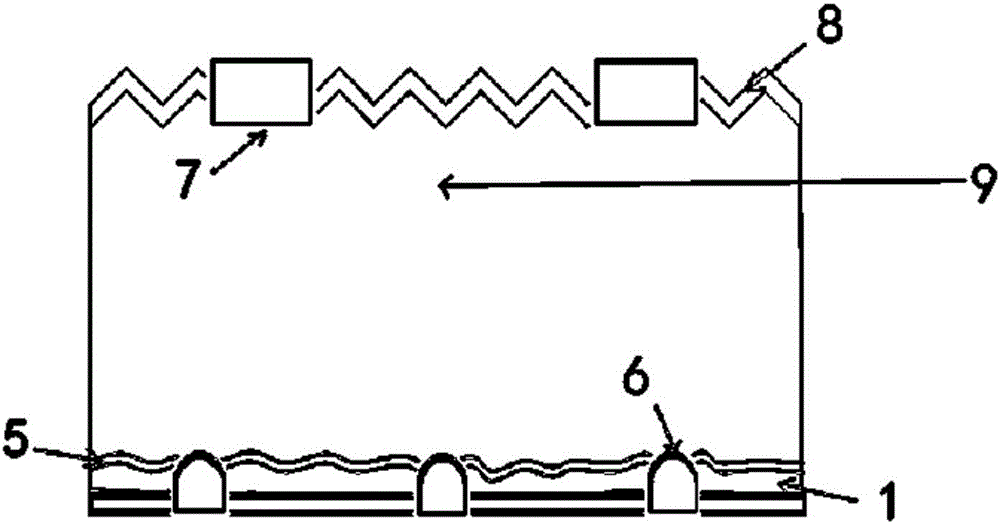

Method used

Image

Examples

Embodiment 1

[0034] a. Preparation of metallurgical grade substrate silicon wafer

[0035] The preparation of the substrate silicon wafer uses a physical purification method. Firstly, metal silicon with a purity of 2N is taken, and metal elements and boron elements are removed by blowing slagging method to obtain metal silicon with a purity of 3N. The metal silicon with a purity of 3N is pickled to remove metal Elements, boron and phosphorus elements, and then cast ingots to obtain silicon ingots with a purity of 4N, cut the silicon ingots into 156mm x 156mm wide, and 500μm thick substrate silicon wafers, and clean the substrate silicon wafers according to standard semiconductor cleaning processes .

[0036] The minority carrier lifetime of the substrate silicon wafer is 5 μs, and the resistivity is 2.4 Ohmcm. Among them, the requirements for main impurities in the substrate silicon wafer: B<2ppmw, P<3ppmw, Fe<0.16ppmw, Al<0.2ppmw, Ca< 0.2ppmw.

[0037] The key of this step lies in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com