Method and device for analyzing oil-string casing failure

A technology of oil layer and casing, which is applied in the field of analysis of failure of oil layer casing, can solve the problems of poor accuracy, wrong analysis results, large differences, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The embodiment of the present invention provides a method for analyzing the failure of oil layer casing, such as figure 1 As shown, the processing flow of the method may include the following steps:

[0040] Step 101, obtaining the geological parameters and engineering parameters of strata at different depths within the preset range where the target oil and gas well is located, wherein the geological parameters include stratum inclination angle, stratum lithology profile, stratum rock mechanics parameter profile, stratum in-situ Stress profile and fault information within the preset range where the target oil and gas well is located. Engineering parameters include the well trajectory of the target oil and gas well, cementing quality information, perforation position information, fracturing construction parameters, and casing damage position information.

[0041] Step 102, according to the geological parameters and engineering parameters, determine the information of the...

Embodiment 2

[0045] An embodiment of the present invention provides a method for analyzing casing failure in an oil layer, and the execution subject of the method is a terminal. Wherein, the terminal may be any terminal, such as a notebook computer.

[0046] The following will combine specific implementation methods, figure 1 The processing flow shown is described in detail, and the content can be as follows:

[0047] Step 101, obtaining the geological parameters and engineering parameters of strata at different depths within the preset range where the target oil and gas well is located, wherein the geological parameters include stratum inclination angle, stratum lithology profile, stratum rock mechanics parameter profile, stratum in-situ Stress profile and fault information within the preset range where the target oil and gas well is located. Engineering parameters include the well trajectory of the target oil and gas well, cementing quality information, perforation position information,...

Embodiment 3

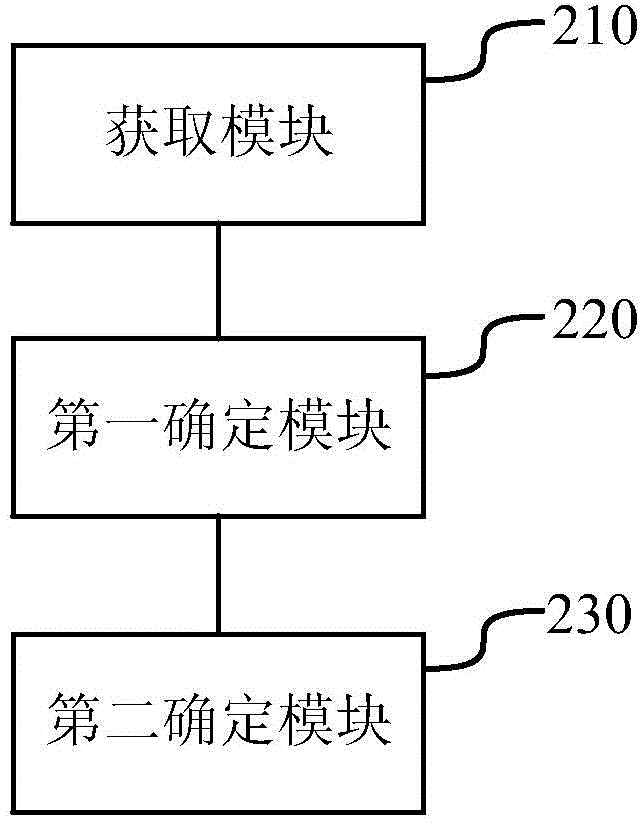

[0074] Based on the same technical idea, the embodiment of the present invention also provides a device for analyzing the failure of the casing in the oil layer, such as figure 2 As shown, the device includes:

[0075] The obtaining module 210 is used to obtain geological parameters and engineering parameters of strata at different depths within the preset range where the target oil and gas well is located, wherein the geological parameters include stratum inclination angle, stratum lithology profile, stratum rock mechanics parameter profile, stratum The in-situ stress profile of the target oil and gas well and the fault information within the preset range of the location of the target oil and gas well. Engineering parameters include the well trajectory of the target oil and gas well, cementing quality information, perforation position information, fracturing construction parameters, casing damage location information;

[0076] The first determination module 220 is used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com