Combined Mechanical Injection-Piezoelectric Jet Mixed Fuel Injection Device

A fuel injection device and injection device technology, applied in fuel injection devices, fuel injection devices with piezoelectric elements or magnetostrictive elements, fuel injection control, etc., can solve the problems affecting engine power and fuel economy, gas injection Pressure and injection rate reduction, adverse effects of gas injection stability and other problems, to achieve the effect of improving gas injection instability, increasing gas injection pressure and injection rate, and meeting the requirements of injection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

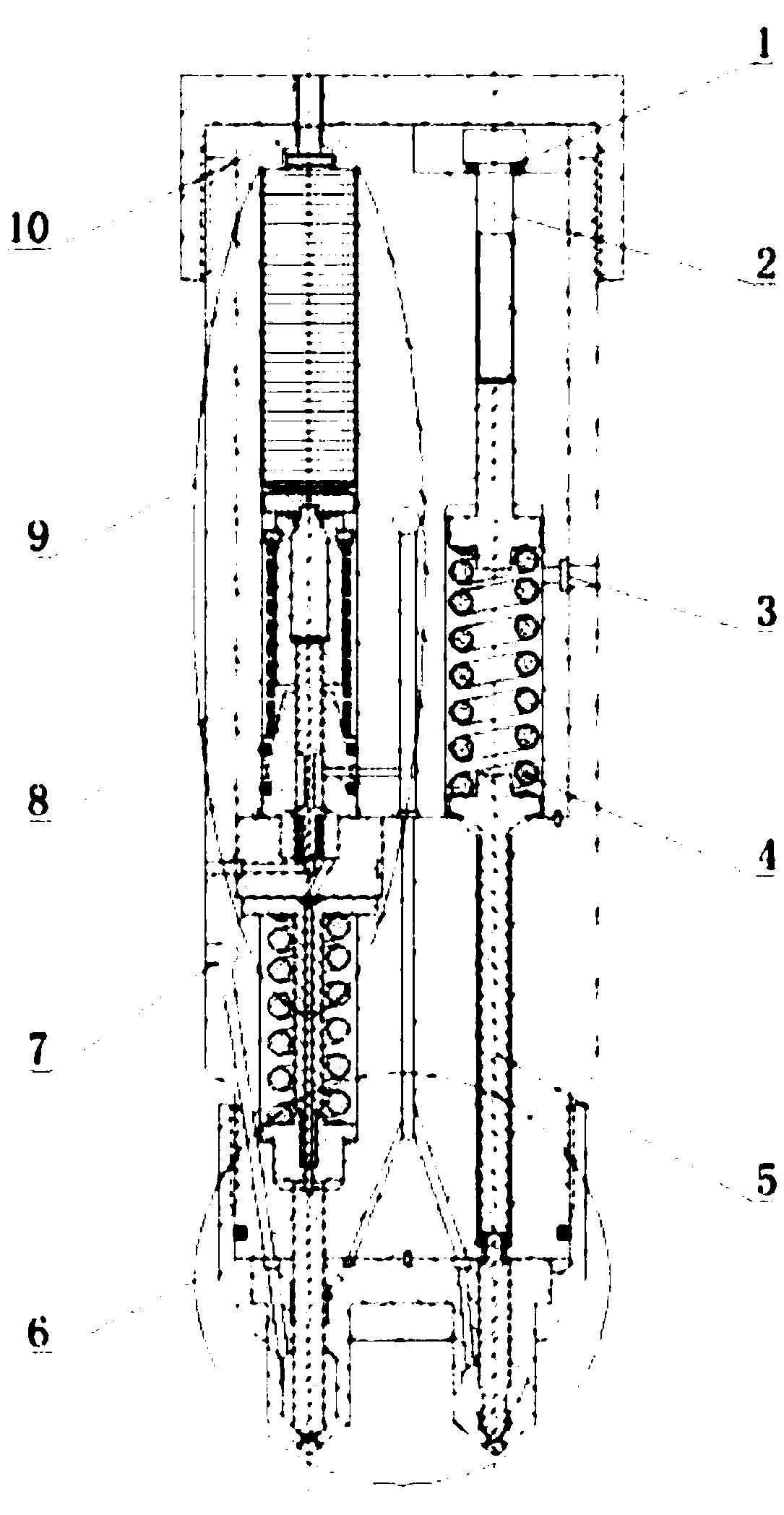

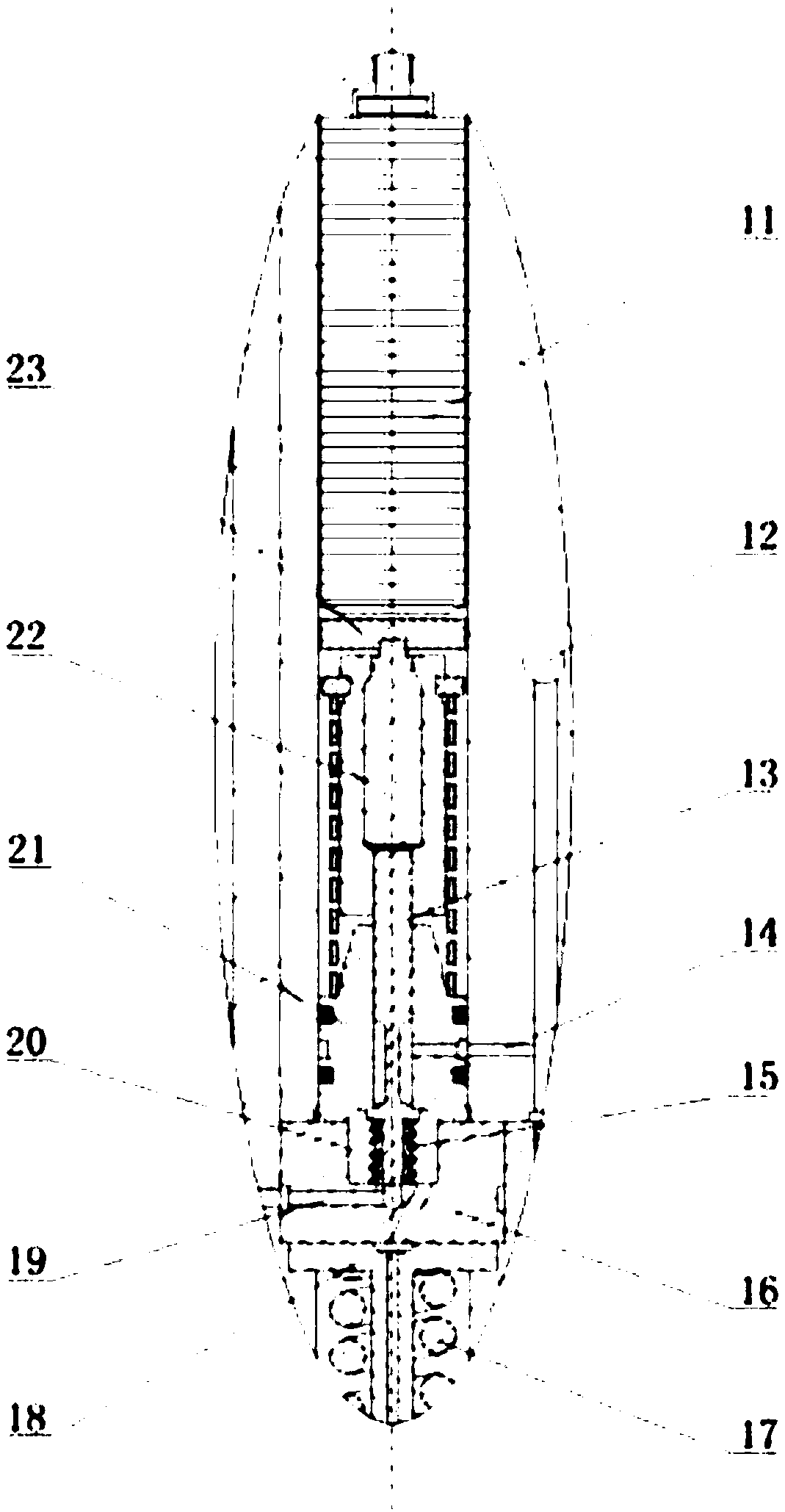

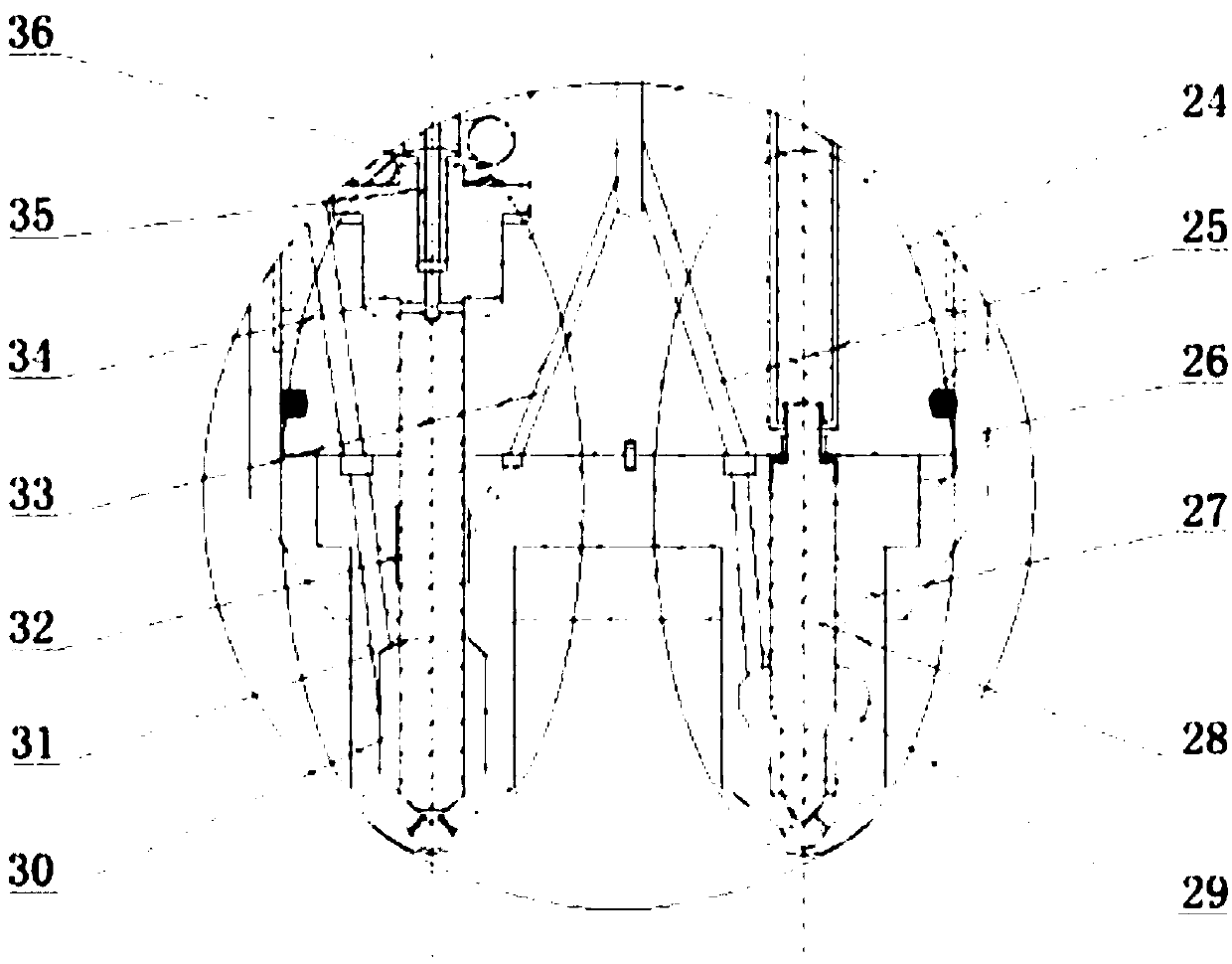

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0017] combine Figure 1~3 , the combined mechanical fuel injection-piezoelectric jet mixed fuel injection device of the present invention mainly includes a piezoelectric control part 9, a nozzle part 6, a control device housing 10, an injection device housing 8, an air intake passage 7, an oil inlet passage 12, Pressure adjusting screw 2, washer 1. The piezoelectric control part 9 mainly includes a piezoelectric element 11, a metal gasket 23, a conversion piston 22, a control valve 13, a control valve seat 21, a control valve return spring 15, a control valve return spring seat 16, a first oil inlet 14, The control valve oil chamber 20, the oil drain port 19, the piezoelectric element 11 is installed inside the control device housing 10, the metal gasket 23 is arranged under the piezoelectric element 11, the changing piston 22 is stuck on the metal gasket 23, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com