Efficient freezing and trimming process for rubber products

A rubber product and trimming technology, which is applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problem of not being able to effectively apply the requirements of large quantities, high efficiency and high quality of rubber products, affecting the quality of rubber product trimming, spraying In order to reduce the probability of clogging and jamming, improve the sensing accuracy and synchronization, and maintain stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

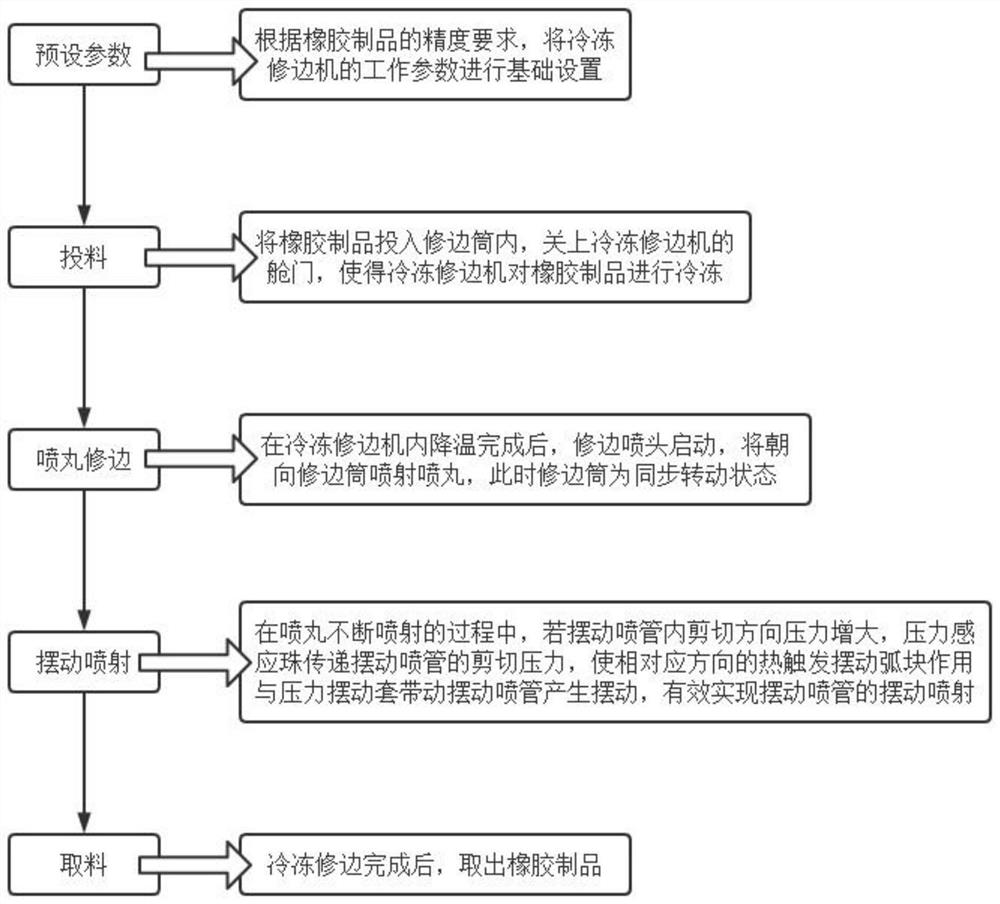

[0048] see Figure 1-10 , an efficient freezing trimming process for rubber products, comprising the following steps:

[0049] S1. Preset parameters, according to the precision requirements of rubber products, basic setting of the working parameters of the frozen trimmer 1;

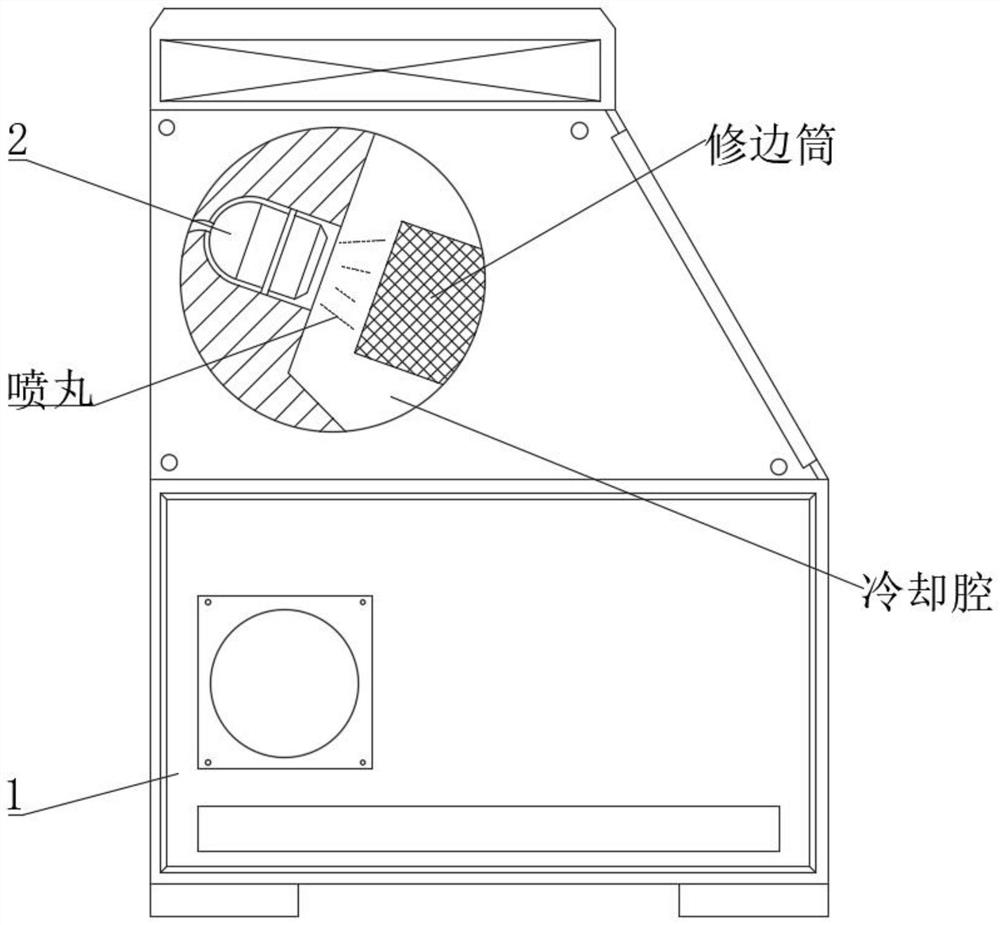

[0050] S2. Feeding, putting the rubber product into the trimming cylinder, and closing the hatch of the refrigerated trimmer 1, so that the refrigerated trimmer 1 freezes the rubber product;

[0051] S3. Shot peening and trimming, after the cooling in the freezer trimming machine 1 is completed, the trimming nozzle 2 is started, and the shot peening will be sprayed toward the trimming cylinder, and the trimming cylinder is in a synchronous rotation state at this time;

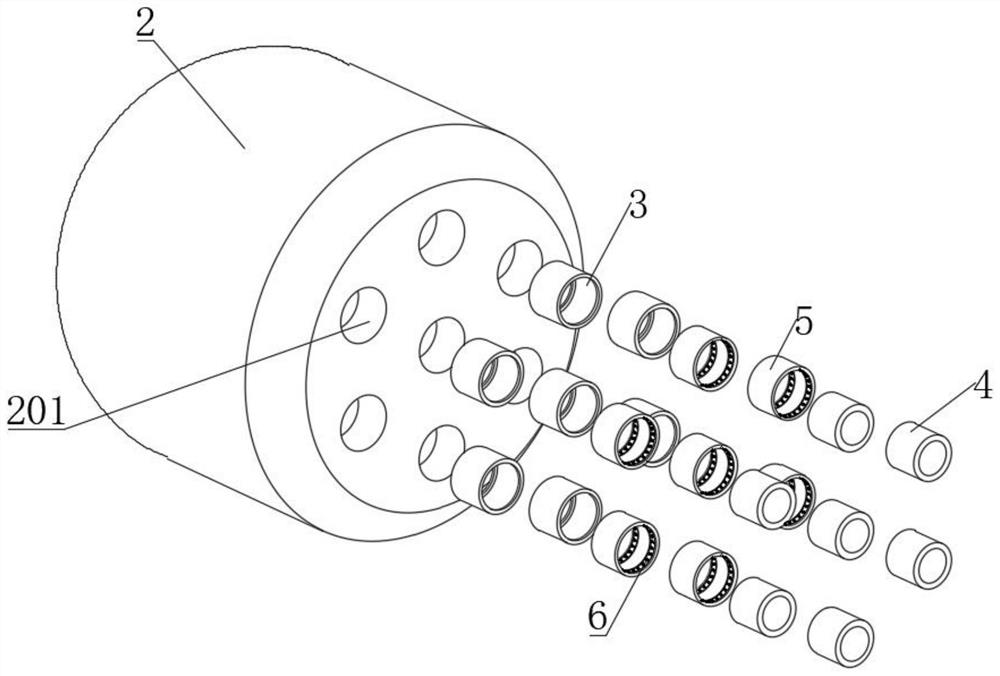

[0052] S4. Swing jet, in the process of continuous shot peening, if the pressure in the shearing direction of the swing nozzle 4 increases, the pressure sensing beads 6 transmit the shear pressure of the swing nozzle 4, so that the heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com