An etching line process for increasing fishing line

A technology of fishing line and etching line, which is applied in the direction of surface etching composition, input/output process of data processing, conductive/antistatic filament manufacturing, etc., which can solve the problem of affecting touch screen performance and product yield, and is prone to warping , Low etching efficiency and other issues, to achieve the effect of uniform and stable etching, neat edges of electrode patterns, and high etching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] An etching line process for increasing fishing line, comprising the following steps:

[0061] (1) Provide a flexible substrate 2, the flexible substrate 2 includes an ITO conductive layer, and screen-print an etching-resistant ink layer on the surface of the ITO conductive layer;

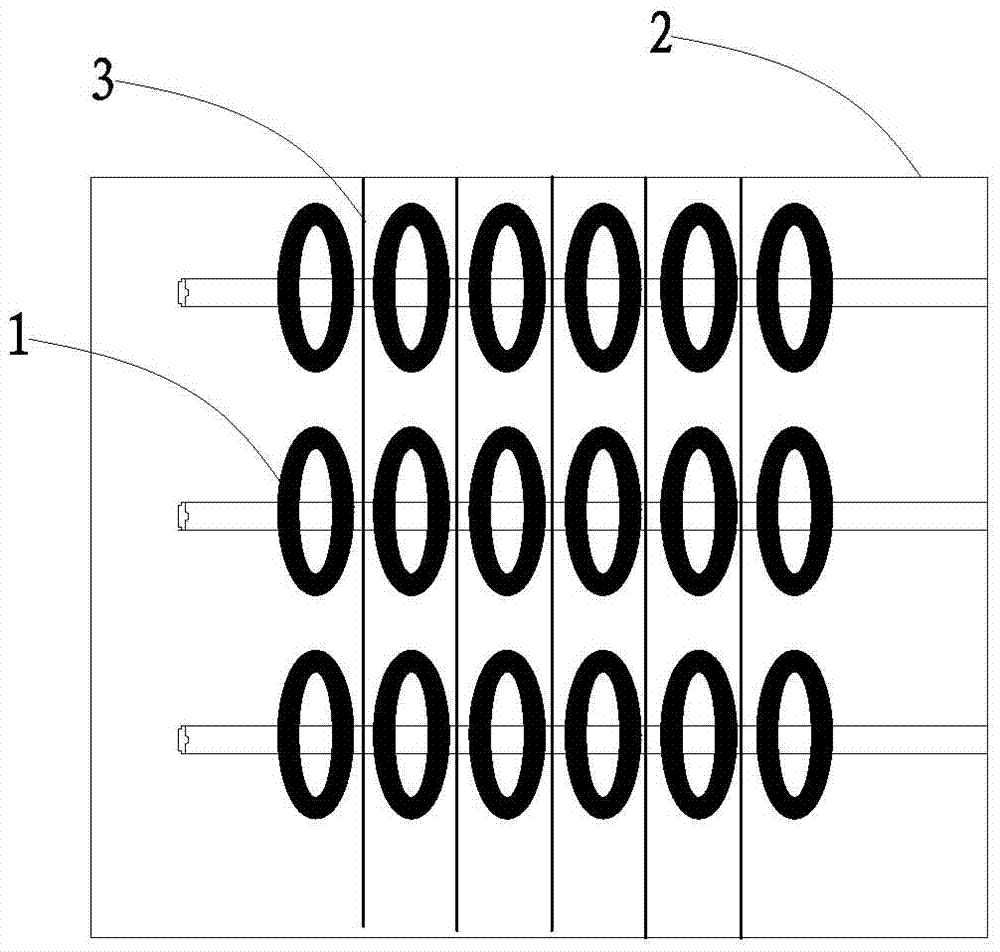

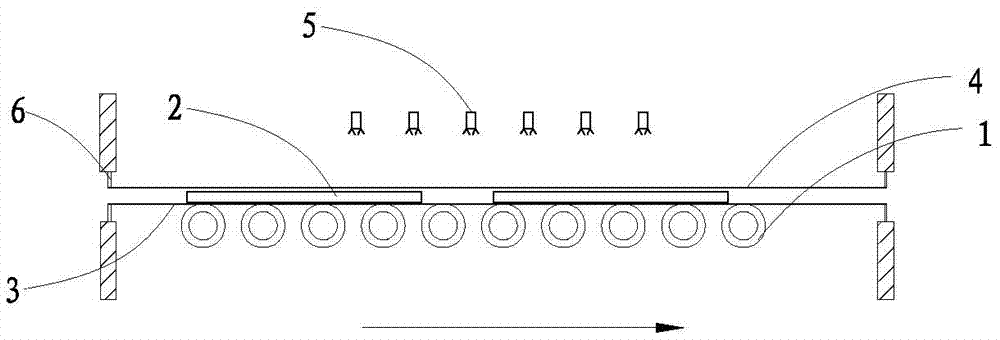

[0062] (2) Enabling etching equipment to etch the flexible substrate 2. The etching equipment includes a processing chamber, and a spraying device and a conveying device are arranged in the processing chamber. The spraying device includes a plurality of nozzles 5; It includes a plurality of coaxial rollers 1, a first fishing line 3 contacting the lower surface of the flexible substrate 2 is arranged between adjacent rollers 1, the first fishing line 3 extends toward the moving direction of the flexible substrate 2, and a fishing line 3 is arranged in the processing chamber. Line fixing part 6, the two ends of the first fishing line 3 are fixed on the fishing line fixing part 6, the first fish...

Embodiment 2

[0092] In this embodiment, the first fishing line 3 in the step (2) includes the following components in mass percentage:

[0093] Polycaprolactam 40%

[0094] Modified epoxy resin 40%

[0095] Polyhexamethylene adipate 10%

[0096] Nano carbon fiber 5%

[0097] Liquid polybutadiene 4.8%

[0098] Vinyl bis-stearamide 0.2%.

[0099] Further, the modified epoxy resin is modified furfural epoxy resin.

[0100] Further, the particle size of carbon nanofibers is 30nm.

[0101] Further, the preparation process of the first fishing line 3 in the step (2) includes the following steps:

[0102] The components are mixed evenly in proportion, melted and extruded at 250°C, the polymer melt is cooled and formed through the spinning process, and the cooled and formed filaments are stretched, heat-treated and shaped, and wound.

[0103] The etching solution in the step (2) includes the following components in mass percentage:

[0104] Hydrochloric acid 30%

[0105] Acetic acid 20 % ...

Embodiment 3

[0115] In this embodiment, the first fishing line 3 in the step (2) includes the following components in mass percentage:

[0116] Polycaprolactam 70%

[0117] Modified epoxy resin 20%

[0118] Polyhexamethylene adipate 4%

[0119] Nano carbon fiber 1%

[0120] Liquid polybutadiene 4%

[0121] Vinyl Bis Stearamide 1%.

[0122] Further, the modified epoxy resin is modified furfural epoxy resin.

[0123] Further, the particle size of the carbon nanofiber is 100nm.

[0124] Further, the preparation process of the first fishing line 3 in the step (2) includes the following steps:

[0125] The components are mixed evenly in proportion, melted and extruded at 255°C, the polymer melt is cooled and formed through the spinning process, and the cooled and formed filaments are stretched, heat-treated and shaped, and then wound.

[0126] The etching solution in the step (2) includes the following components in mass percentage:

[0127] Hydrochloric acid 50%

[0128] Acetic acid 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com