Hydroxyl silicone oil and continuous preparation method thereof

A technology of hydroxysilicone oil and hexamethylcyclotrisiloxane, which is applied in the field of hydroxysilicone oil and its continuous preparation, can solve the problems of small effective surface area, low catalytic efficiency, and low conversion rate, and achieve large contact area, slow down Dehydration condensation reaction, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

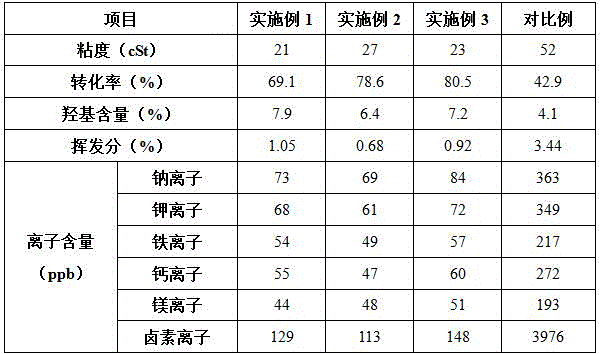

Examples

preparation example Construction

[0026] A continuous preparation method of hydroxy silicone oil, comprising the following steps:

[0027] 1) Add hexamethylcyclotrisiloxane, solvent and water into a mixing tank, stir and mix evenly, then transfer to a fluidized bed equipped with a catalyst to fully react;

[0028] 2) Adsorption filtration, ultrafiltration membrane filtration, delowering under normal pressure, delowering under reduced pressure to obtain hydroxyl silicone oil, recover solvent and unreacted low molecular compounds, and recycle after checking the content of each component.

[0029] Preferably, the molar ratio of hexamethylcyclotrisiloxane, solvent and water in step 1) is 1: (1-5): (1.2-1.5).

[0030] Preferably, the solvent in step 1) is at least one of dichloromethane, tetrahydrofuran, chloroform, acetone, and methanol.

[0031] Preferably, the catalyst in step 1) is Nafion / SiO 2 A nanocomposite material, wherein the mass fraction of Nafion is 5-40%.

[0032] Further preferably, the Nafion / SiO...

Embodiment 1

[0040] 1) Add hexamethylcyclotrisiloxane, methanol and deionized water into the mixing tank according to the molar ratio of 1:2:1.5, and stir and mix for 30 minutes;

[0041] 2) Transfer the material into a Nafion / SiO 2 Catalytic reaction at 60°C for 40 minutes in a fluidized bed of nanocomposite material (Nafion mass fraction is 13%);

[0042] 3) Carry out adsorption filtration and ultrafiltration membrane filtration;

[0043] 4) Under normal pressure at 100°C for 40 minutes;

[0044] 5) Under the conditions of 180°C and vacuum degree less than -0.099MPa, carry out decompression for 2 hours to obtain hydroxyl silicone oil. The solvent and unreacted low molecular weight compounds in the reaction system enter the reaction system for recycling after detecting the content of each component .

Embodiment 2

[0046] 1) Add hexamethylcyclotrisiloxane, acetone and deionized into the mixing tank according to the molar ratio of 1:4:1.2, and stir and mix for 20 minutes;

[0047] 2) Transfer the material into a Nafion / SiO 2 Catalytic reaction at 50°C for 50 minutes in a fluidized bed of nanocomposite material (Nafion mass fraction is 20%);

[0048] 3) Carry out adsorption filtration and ultrafiltration membrane filtration;

[0049] 4) Under normal pressure at 80°C for 60 minutes;

[0050] 5) Under the conditions of 150°C and vacuum less than -0.099MPa, carry out decompression for 3 hours to obtain hydroxyl silicone oil. The solvent and unreacted low-molecular compounds in the reaction system enter the reaction system for recycling after detecting the content of each component .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com