A kind of peelable blue glue and preparation method thereof

A blue glue, curing resin technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of residue, cumbersome peeling process, long curing time of peelable blue glue, etc. Interactions, effects of low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

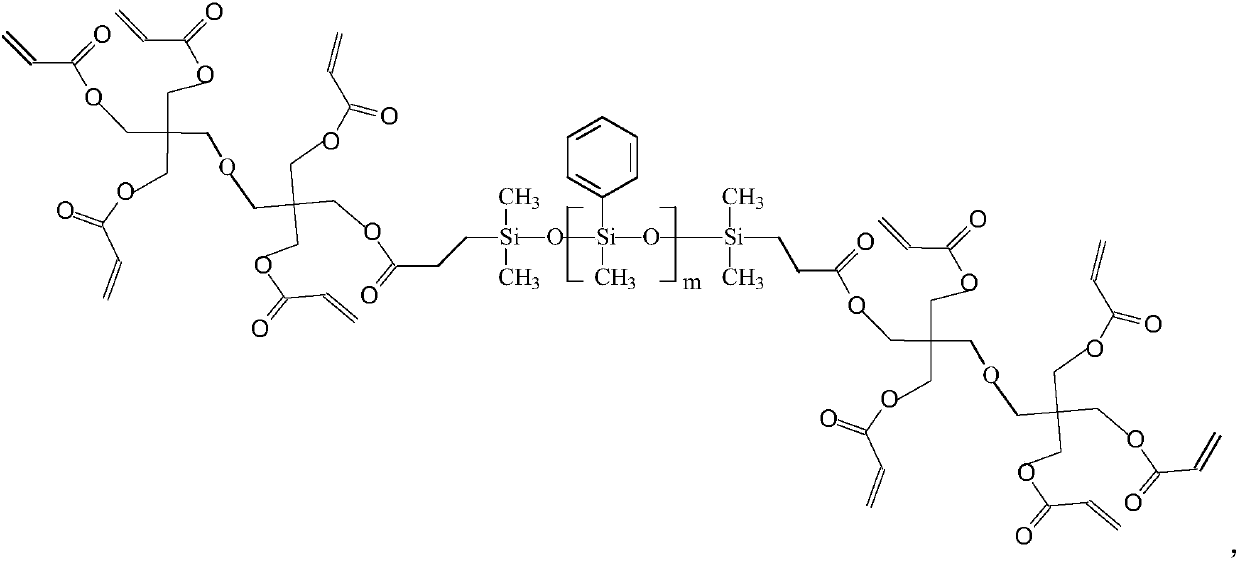

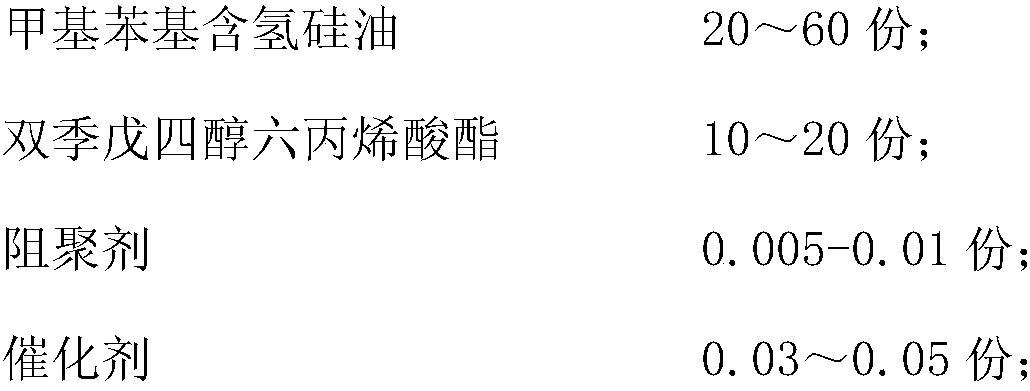

[0084] A kind of peelable blue glue, calculated by weight, its raw material composition and content are as follows:

[0085] 50 parts of UV curing resin A;

[0086] 50 parts of UV curing resin B;

[0087] 50 parts of UV curing resin C;

[0088] Leveling agent 0.05 parts;

[0089] 1 part of wetting agent;

[0090] 0.2 part of defoamer;

[0091] 1 part of color paste;

[0092] 3 parts of photoinitiator A;

[0093] 3 parts of photoinitiator B;

[0094] Wherein said UV curable resin A is calculated in parts by weight, and its composition and content are as follows:

[0095] 20 parts of methyl phenyl hydrogen silicone oil;

[0096] 10 parts of dipentaerythritol hexaacrylate;

[0097] 0.005 part of polymerization inhibitor;

[0098] Catalyst 0.03 part;

[0099] Described UV curing resin A is prepared as follows:

[0100] Add 20 parts of methylphenyl hydrogen-containing silicone oil and 10 parts of dipentaerythritol hexaacrylate into a 500ml three-necked flask, then add 0...

Embodiment 2

[0115] A kind of peelable blue glue, calculated by weight, its raw material composition and content are as follows:

[0116] 80 parts of UV curing resin A;

[0117] 80 parts of UV curing resin B;

[0118] 80 parts of UV curing resin C;

[0119] Leveling agent 0.1 parts;

[0120] 10 parts of wetting agent;

[0121] 1 part of defoamer;

[0122] 10 parts of color paste;

[0123] 5 parts of photoinitiator A;

[0124] 5 parts of photoinitiator B;

[0125] Wherein said UV curable resin A is calculated in parts by weight, and its composition and content are as follows:

[0126] 60 parts of methyl phenyl hydrogen silicone oil;

[0127] 20 parts of dipentaerythritol hexaacrylate;

[0128] Inhibitor 0.01 part;

[0129] Catalyst 0.05 part;

[0130] Described UV curing resin A is prepared as follows:

[0131] Add 60 parts of methylphenyl hydrogen-containing silicone oil and 20 parts of dipentaerythritol hexaacrylate into a 500ml three-necked flask, then add 0.01 part of polymeri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com