Sapo‑34 molecular sieve with adjustable micropore diameter, preparation method and application

A technology of SAPO-34 and micropore diameter, which is applied in the field of catalyst preparation, can solve problems such as the difficulty in adjusting the ratio of ethylene and propylene, and achieve the effects of simple method, good shape-selective separation performance, and reliable repeatable zeolite application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

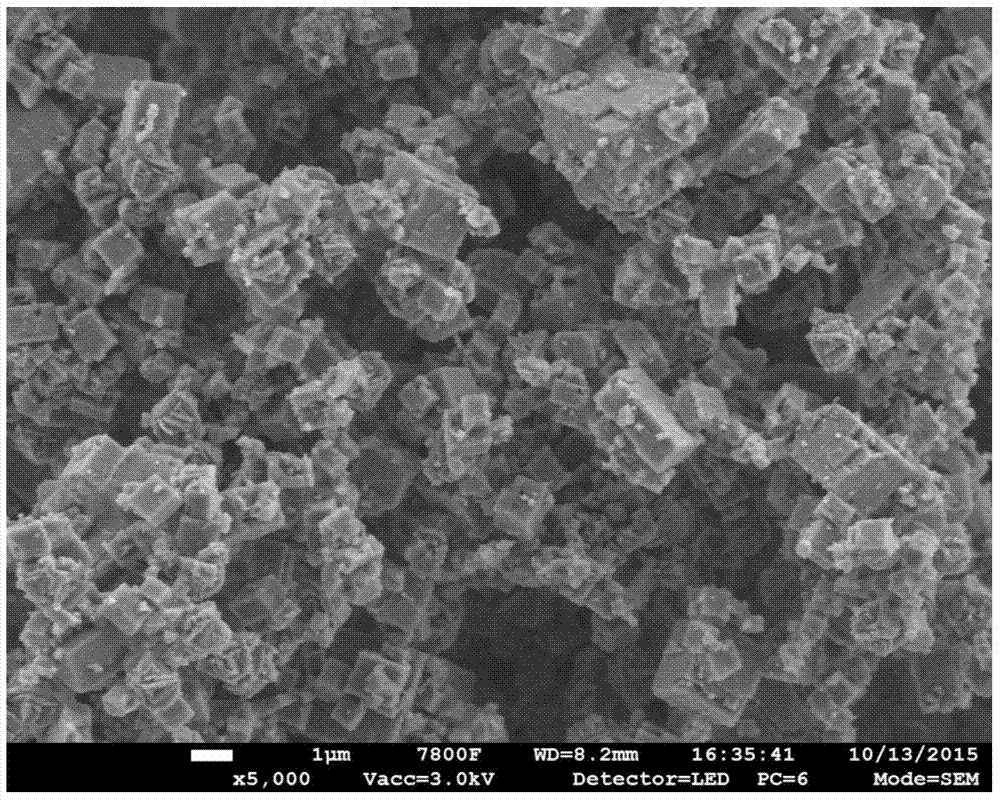

Embodiment 1

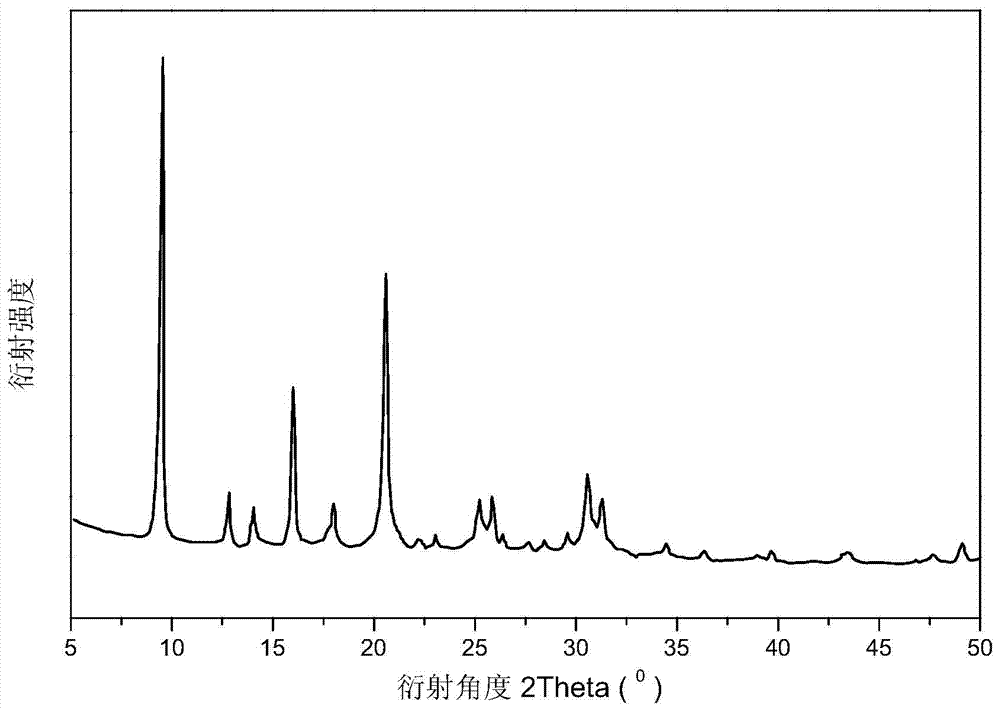

[0042] A SAPO-34 molecular sieve with adjustable micropore diameter is prepared by the following method:

[0043] (1) Preparation of SAPO-34 molecular sieve:

[0044] Weigh 14.57g of SB powder, dissolve it in 88.27g of deionized water and stir evenly at room temperature, then add 11.53g of orthophosphoric acid with a mass fraction of 85% and continue to stir evenly for 2 hours, filter the slurry, dry at 120°C for 2h, and roast at 450°C for 2h Obtain phosphoaluminum dry glue, and then pulverize to obtain particles of ≤100 μm;

[0045] Mix and stir all the particles obtained above with 0.31g of white carbon black, 45g of deionized water, 11.78g of tetraethylammonium hydroxide and 3.07g of triethylamine, and transfer the uniformly mixed gel to a stainless steel autoclave, 500 rpm After stirring at a speed of 0.5h per minute, stir and crystallize at 140°C for 24h, then raise the temperature to 170°C and crystallize for 48h; After drying at ℃ for 12 hours, the raw molecular sieve...

Embodiment 2

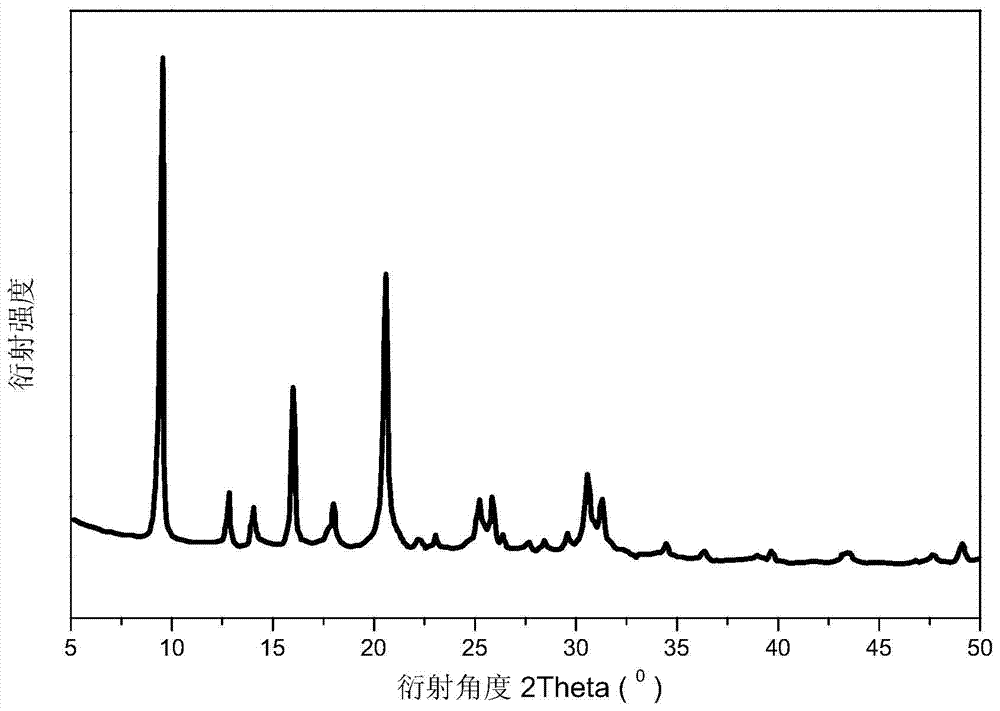

[0050] A SAPO-34 molecular sieve with adjustable micropore diameter, the preparation method is basically the same as in Example 1, the difference is that in step 2, the precipitant SiCl 4 The addition amount of 0.1ml is 0.05mol, and the prepared product is marked as SAPO-34 molecular sieve A2. The results of the pore structure measured by N2 isothermal adsorption-desorption are shown in Table 1.

Embodiment 3

[0052] A SAPO-34 molecular sieve with adjustable micropore diameter, the preparation method is basically the same as in Example 1, the difference is that in step 2, the precipitant SiCl 4 The addition amount of 0.15ml is 0.075mol, and the prepared product is marked as SAPO-34 molecular sieve A3, and the pore structure results obtained by N2 isothermal adsorption-desorption are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com