A device for processing garlic slices

A processing device and garlic slice technology, applied in metal processing and other directions, can solve the problems of time-consuming, labor-intensive, low-efficiency, and difficult to meet quickly, and achieve the effects of cost reduction, quick adjustment and conversion, and convenient assembly, disassembly, maintenance and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

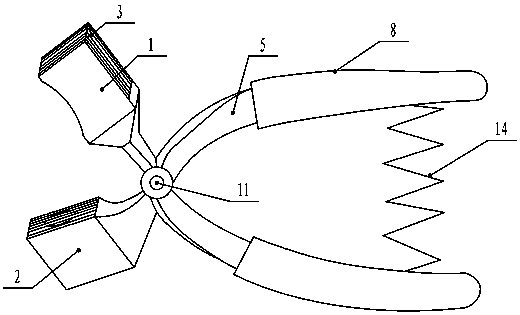

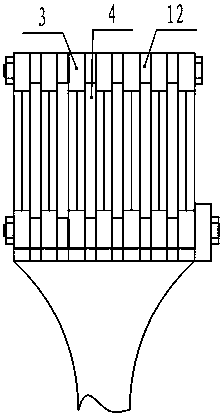

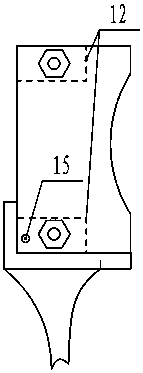

[0021] Embodiment 1: as Figure 1~Figure 6 As shown, a garlic slice processing device includes a main blade group 1 and a slave blade group 2, the main blade group 1 and the slave blade group 2 can rotate around a rotating shaft 11, and a rotating handle 5 is provided at the tail end, and the main blade group 1 There are multiple main blades 3, and a gap 4 is provided between every two adjacent main blades 3. The slave blade group 2 has multiple slave blades 6, and a gap 2 7 is provided between every two adjacent slave blades 6. The main blades 3 are positive For the gap two 7, the secondary blade 6 is facing the gap one 4, the thickness of the secondary blade 6 is smaller than the gap one 4, the cutting edge of the secondary blade 6 is flat, the cutting edge of the main blade 3 is sharp, the main blade group 1 and the secondary blade group 2 is provided with positioning pin 15, and positioning pin 15 is convenient for the rapid installation of the main blade and the slave bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com