Welding method for circumferential weld of thick-wall nickel-based alloy header

A technology of nickel-based alloys and welding methods, which is applied to the welding of deep grooves of nickel-based alloy thick-walled pipes and the welding field of nickel-based alloys, which can solve the problems of high linear expansion coefficient, large shrinkage deformation, and reduced weld performance of nickel-based alloys And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

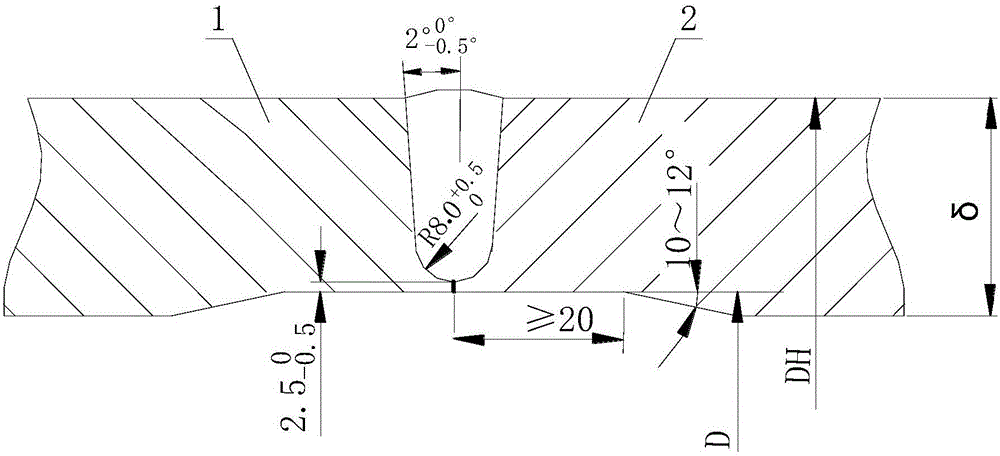

[0052] A method for welding the girth weld of a thick-walled nickel-based alloy header according to the present invention, wherein the wall thickness δ of the nickel-based alloy header is 30-150mm, and the method comprises the following steps:

[0053] S1: Selection of welding consumables

[0054] Use homogeneous welding materials: the wire grade is ERNiCrCo-1.

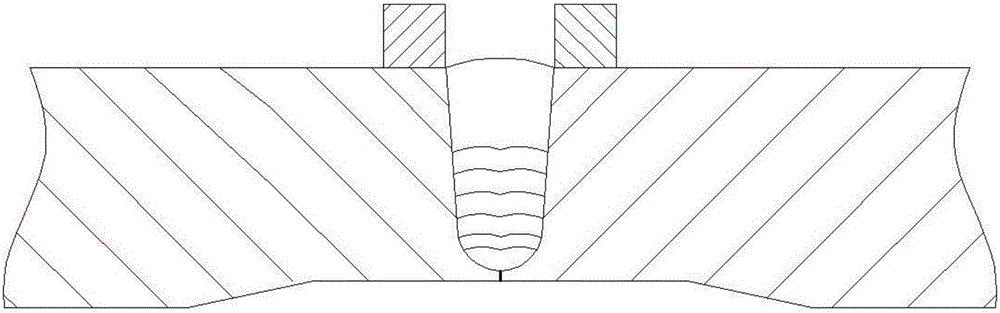

[0055] S2: Selection of welding method

[0056] Hot wire TIG welding is adopted, the thickness of the welding torch is H12mm, the welding head has the function of two-way shielding gas, and the tungsten pole can swing during the welding process.

[0057] S3: Preparation before welding

[0058] Such as figure 1 As shown, respectively measure the wall thickness of the joint of the first nickel-based alloy header cylinder 1 and the second nickel-base alloy header cylinder 2 to be welded, and according to the difference between the two wall thicknesses, the two nickel-based alloy header cylinders The inner wall of the...

Embodiment 2

[0074] The specific implementation steps of this embodiment are roughly the same as those of Embodiment 1, except that step S44: welding, and the welding includes the following sub-steps:

[0075] S441: Back welding, current 160A, voltage 10V, welding speed 80-120mm / min, tungsten electrode does not swing during welding;

[0076] S442: Transition welding, current 200A, voltage 10V, welding speed 90-130mm / min, tungsten electrode swings during welding;

[0077] S443: Filler welding, current 280A, voltage 10V, welding speed 80-120mm / min, tungsten electrode swings during welding;

[0078] S444: Cover welding, current 260A, voltage 10V, welding speed 80-120mm / min, tungsten electrode does not swing during welding.

Embodiment 3

[0080] The specific implementation steps of this embodiment are roughly the same as those of Embodiment 1, except that step S44: welding, and the welding includes the following sub-steps:

[0081] S441: bottom welding, current 200A, voltage 10V, welding speed 80-120mm / min, tungsten electrode does not swing during welding;

[0082] S442: Transition welding, current 240A, voltage 10V, welding speed 90-130mm / min, tungsten swing during welding;

[0083] S443: Filler welding, current 320A, voltage 10V, welding speed 80-120mm / min, tungsten electrode swings during welding;

[0084] S444: Cover welding, current 300A, voltage 10V, welding speed 80-120mm / min, tungsten electrode does not swing during welding.

[0085] The selection of the welding parameter of step S44 among the table 4. embodiment 1-3

[0086]

[0087] In the above three embodiments, when the bottom welding current is 180A, the excess welding current is 220A, the filling welding current is 300A, and the cover weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com