A method for preparing kombucha solid beverage

A technology for solid beverages and kombucha, which is applied in the field of food processing, can solve problems such as studies that have not yet been reported, and achieve the effects of solving moisture absorption and caking, improving fermentation speed, and increasing nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

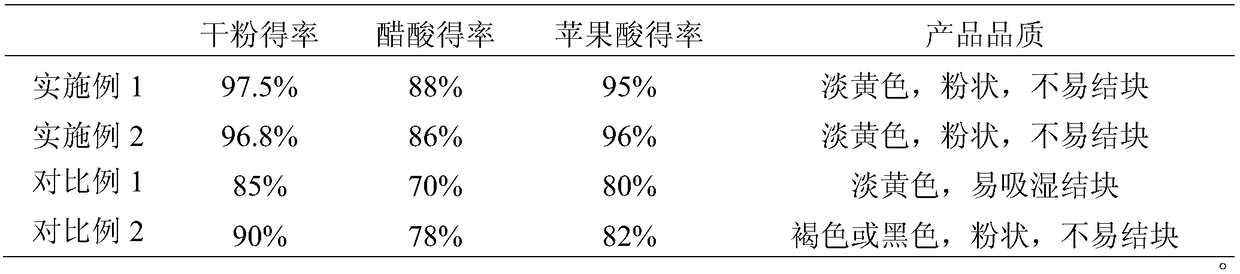

Examples

Embodiment 1

[0033] A kombucha solid beverage, the specific preparation method is as follows:

[0034] (1) Put black tea, apple juice and sucrose into water, boil and cool, filter out the tea leaves, add black tea strains, and ferment at 30°C for 8 days; wherein, the mass ratio of black tea, fruit juice, sucrose, kombucha to water For 1:25:8:12:75, obtain kombucha fermented liquid;

[0035] The acidity of the above-mentioned Kombucha fermented liquid was measured to be 3g / 100ml, the solid content (mass fraction) was 10%, the acetic acid content was 55g / L, and the malic acid content was 0.3g / L.

[0036] (2) Take kombucha fermented liquid and concentrate it in vacuum at 50° C. for 1 hour to obtain concentrated liquid.

[0037] (3) Based on the quality of the solids in the concentrated solution, add 12% of the composite filler to the concentrated solution, and at a speed of 40 to 50 rpm, stir evenly with magnetic force to obtain a mixed solution; wherein, the composite filler The mass ratio...

Embodiment 2

[0043] A kombucha solid beverage, the specific preparation method is as follows:

[0044] (1) Put black tea, apple juice and sucrose into water and boil, then cool, filter out the tea leaves, add black tea strains, and ferment for 9 days at 30°C; wherein, the mass ratio of black tea, fruit juice, sucrose, kombucha and water is 1:30:10:10:70, obtain kombucha fermented liquid;

[0045] The acidity of the above kombucha fermentation liquid was measured to be 3g / 100ml, the solids content was 11%, the acetic acid content was 58g / L, and the malic acid content was 0.35g / L.

[0046] (2) Take kombucha fermented liquid and concentrate it in vacuum at 50° C. for 1 hour to obtain concentrated liquid.

[0047](3) Based on the quality of the solids in the concentrated solution, add 5% of the composite filler to the concentrated solution, and at a speed of 40 to 50 rpm, stir evenly with magnetic force to obtain a mixed solution; wherein, the composite filler The mass ratio of white granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com