Polypeptide iron chelate prepared from soy isolate protein serving as substrate and preparation method

A soybean protein isolate and chelate technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of amino acid imbalance, low polypeptide content, high price, etc., and achieve high social and economic benefits, purity and content. The effect of improving and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

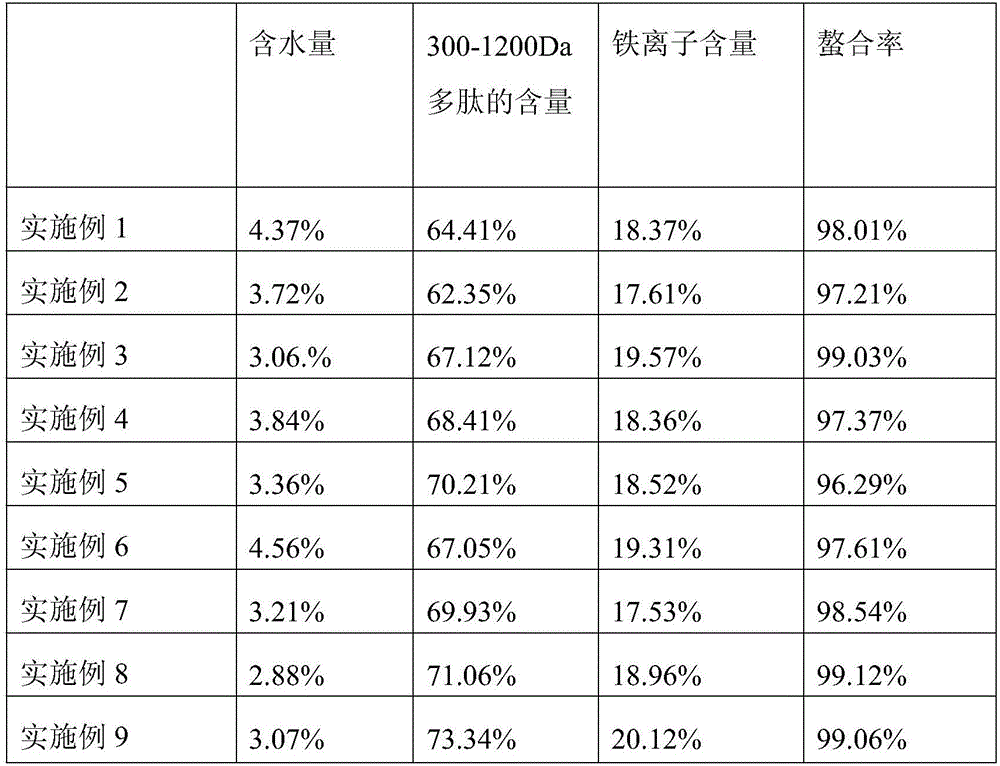

Examples

Embodiment 1

[0043] Embodiment 1: preparation is the polypeptide iron chelate of substrate with soybean protein isolate, comprises the following steps:

[0044] 1) Preparing medium: use soybean protein concentrate as the base material, prepare medium with ultra-fine powder soybean meal and glucose, the weight ratio of soybean protein concentrate: soybean meal: glucose is 85:5:10, soybean meal and glucose provide carbon source and Trace elements required for microbial growth, prepared and mixed evenly, and sterilized by steaming at 105°C;

[0045] 2) Fermentation stage: Prepare three-stage expansion culture strains, in which lactic acid bacteria: yeast = 1:3, and the inoculation concentration is 4×10 7 -9×10 7 cfu / ml, according to the ratio of material to water 1:2.0, mix with appropriate water and mix with the prepared medium evenly, control the fermentation temperature at 37-42°C, and the fermentation time is 42h;

[0046] 3) Enzymolysis stage: mix neutral protease and flavor protease w...

Embodiment 2

[0050] Embodiment 2: preparation is the polypeptide iron chelate of substrate with soybean protein isolate, comprises the following steps:

[0051] 1) Preparation of medium: use soybean protein concentrate as the base material, and prepare medium with ultrafine powder soybean meal and glucose, wherein the weight ratio of soybean protein concentrate: soybean meal: glucose is 85:10:5, and soybean meal and glucose provide carbon Sources and trace elements required for microbial growth, prepared and mixed evenly, and sterilized by steaming, the sterilization temperature is 105°C;

[0052] 2) Fermentation stage: Prepare three-stage expansion culture strains, in which lactic acid bacteria: yeast = 1:3, and the inoculation concentration is 4×10 7 -9×10 7 cfu / ml, according to the ratio of material to water 1:1.2-1:2.5, mix with appropriate water and mix with the prepared medium evenly, control the fermentation temperature at 37-42°C, and the fermentation time is 42h;

[0053] 3) Enz...

Embodiment 3

[0057] Embodiment 3: prepare the polypeptide iron chelate with soybean protein isolate as substrate, comprise the following steps:

[0058] 1) Preparation of medium: use soybean protein concentrate as the base material, and prepare medium with ultrafine powder soybean meal and glucose, wherein the weight ratio of soybean protein concentrate: soybean meal: glucose is 85:8:7, soybean meal and glucose provide carbon Sources and trace elements required for microbial growth, prepared and mixed evenly, and sterilized by steaming, the sterilization temperature is 105°C;

[0059] 2) Fermentation stage: Prepare three-stage expansion culture strains, in which lactic acid bacteria: yeast = 1:3, and the inoculation concentration is 4×10 7 -9×10 7 cfu / ml, according to the ratio of material to water 1:1.2-1:2.5, mix with appropriate water and mix with the prepared medium evenly, control the fermentation temperature at 37-42°C, and the fermentation time is 42h;

[0060] 3) Enzymolysis stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com