Reduction-type electroless gold plating solution and electroless gold plating method using said plating solution

A chemical gold plating and reduction technology, applied in the field of chemical gold plating solution, can solve the problems of increased cost, difficulty in ensuring the safety of plating treatment, poor productivity, etc., and achieve the effects of saving raw materials, good precipitation selectivity, and preventing diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

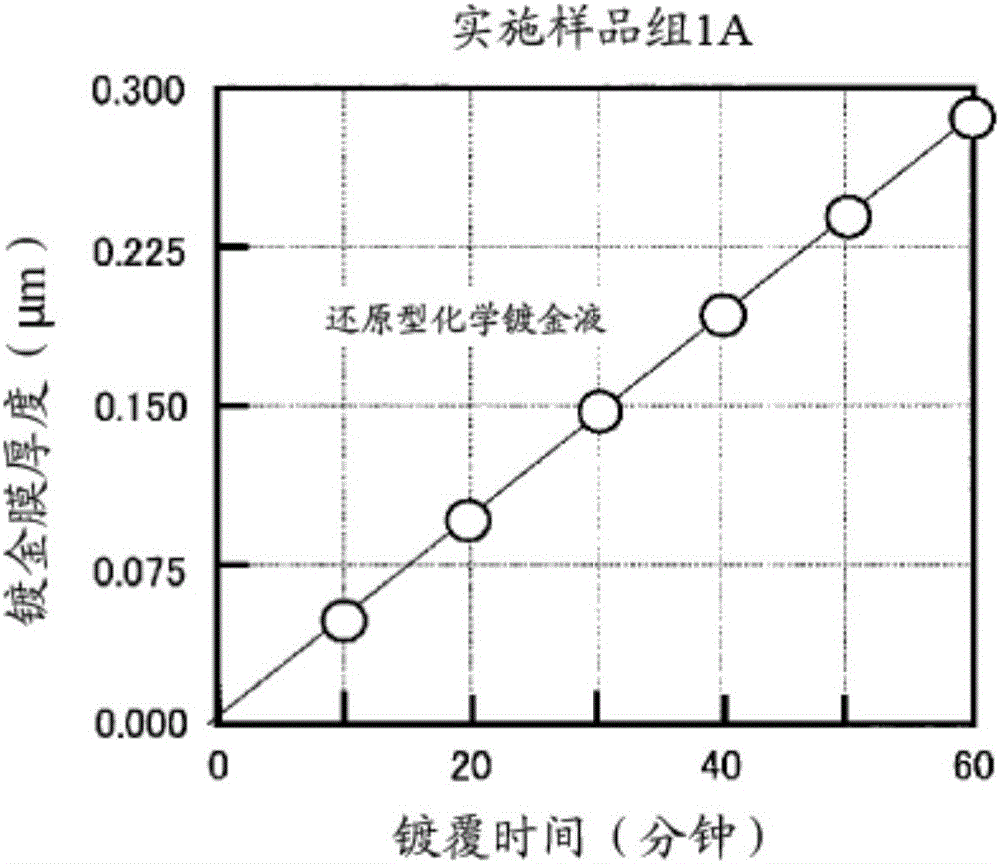

[0077] In Example 1, using the reduced gold plating solution of the present invention, a copper plate is used as a substrate, and a plating film consisting of electroless nickel plating film / electroless palladium plating film / electroless gold plating film is formed on the substrate.

[0078] Adjustment of reduction type electroless gold plating solution: The composition of the reduction type electroless gold plating solution used in the present embodiment is as follows. The plating conditions (pH, liquid temperature) are shown together with the composition.

5mmol / L

Dipotassium EDTA

0.03mol / L

0.15mol / L

3mmol / L

3,3'-Diamino-N-methyldipropylamine

0.02mol / L

Thallium acetate

5mg / L

pH

8.5

80℃

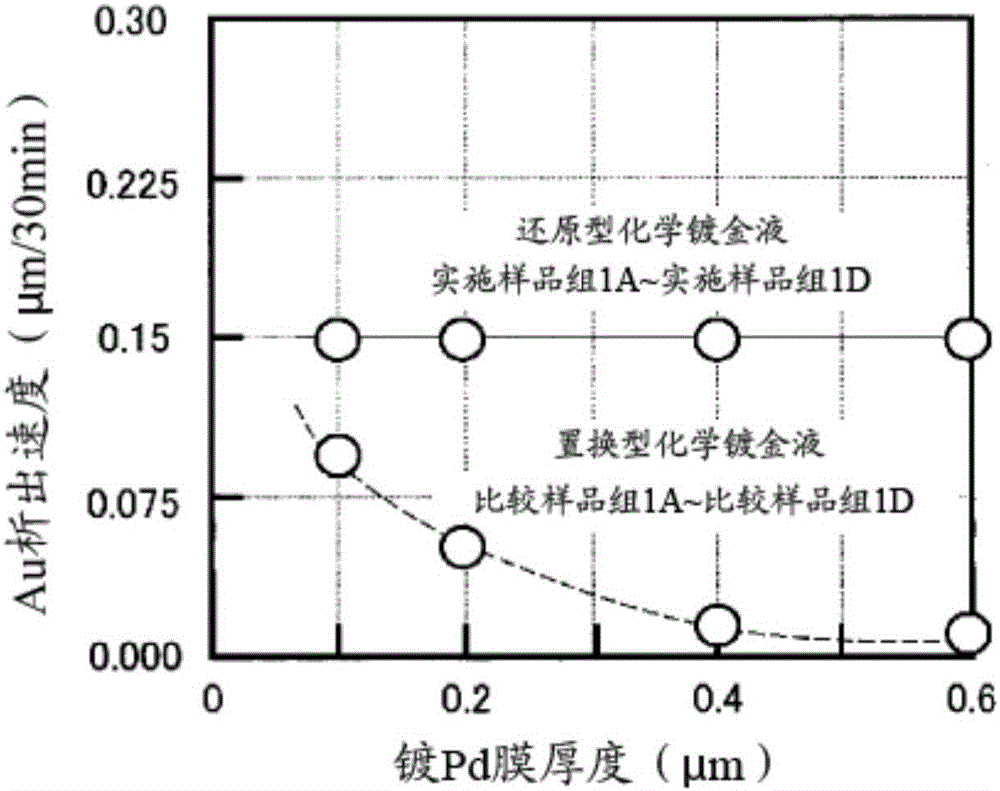

[0080] Manufacture of a coating film: The sample with a coating film of Example 1 consists of implementation sam...

Embodiment 2

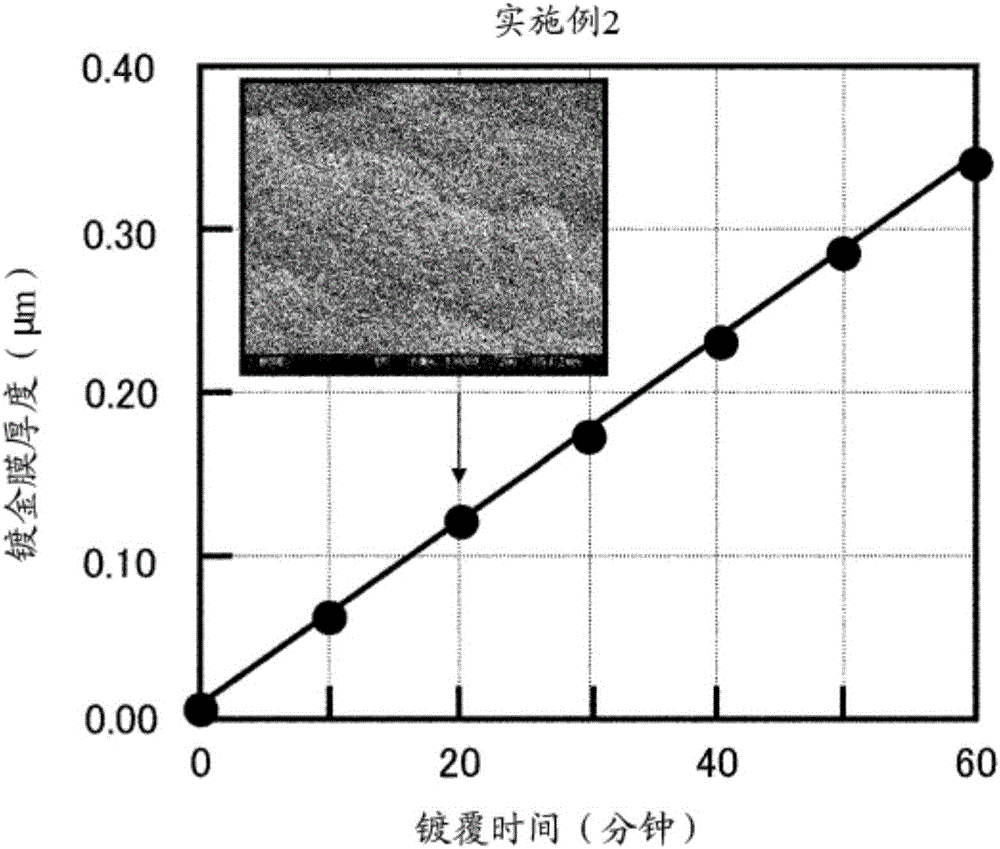

[0086] In embodiment 2, the same reduced gold plating solution as in embodiment 1 was used, and a copper plate was used as a substrate to form a plating film consisting of electroless nickel plating film / replacement type electroless gold plating film / reduction type electroless gold plating film on the substrate. The coating film samples of Example 2 consist of implementation sample 2-1 to implementation sample 2-6. In each of the implementation samples 2-1 to 2-6, an electroless nickel plating film with a film thickness of 5 μm was formed on the surface of the copper plate, and then a displacement type electroless gold plating film with a film thickness of 0.07 μm was formed on the surface of the electroless nickel plating film. Then, using the reduction type electroless gold plating solution, a reduction type electroless gold plating film is formed on the surface of the displacement type electroless gold plating film according to each plating time condition. In addition, each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com