A carbon-sulfur composite for positive electrode of lithium-sulfur battery and its preparation and application

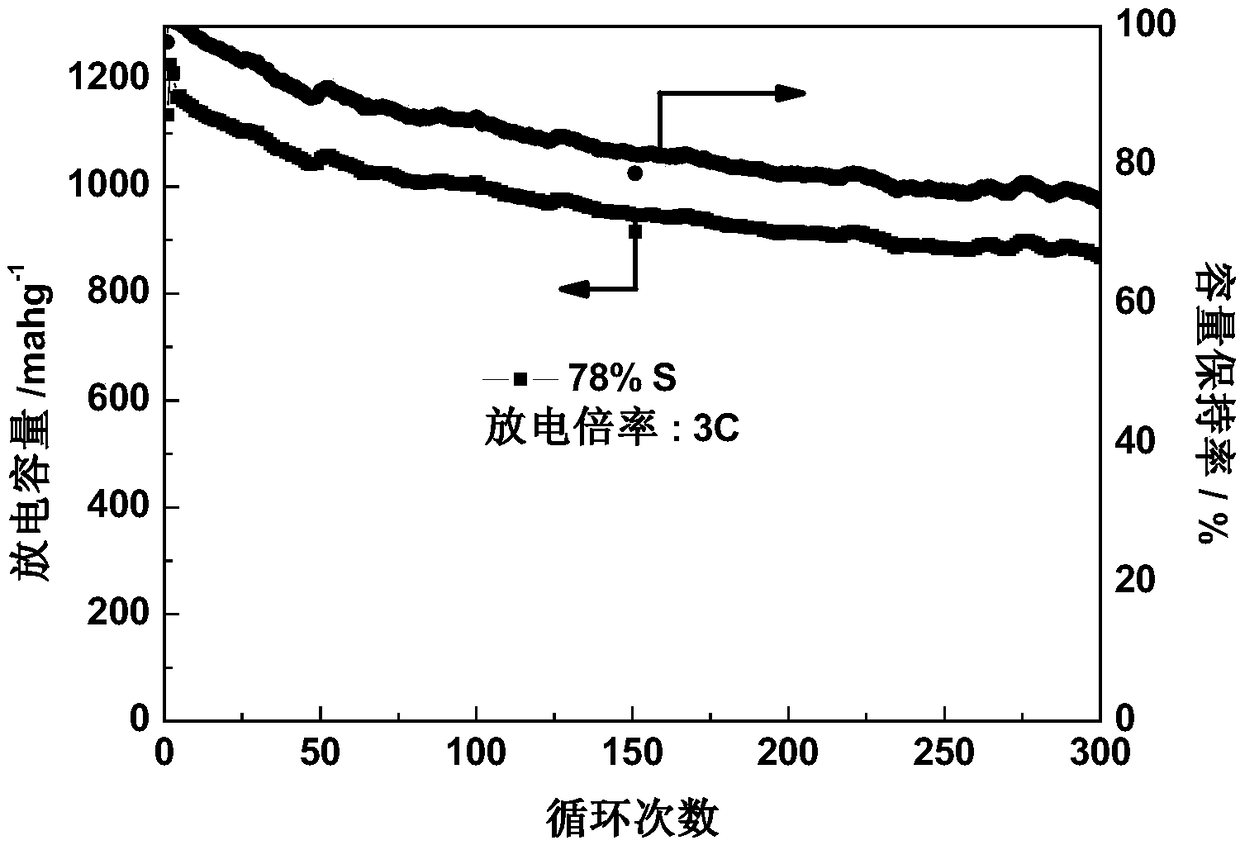

A lithium-sulfur battery and composite technology, which is applied in the field of nanocomposite materials and its preparation, can solve the problems of low utilization rate of active material sulfur, restrictions on industrialized large-scale production, unsafe and environmentally friendly thiophene, etc., achieve good cycle stability, and benefit Diffusion and transport, the effect of improving electrochemical capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

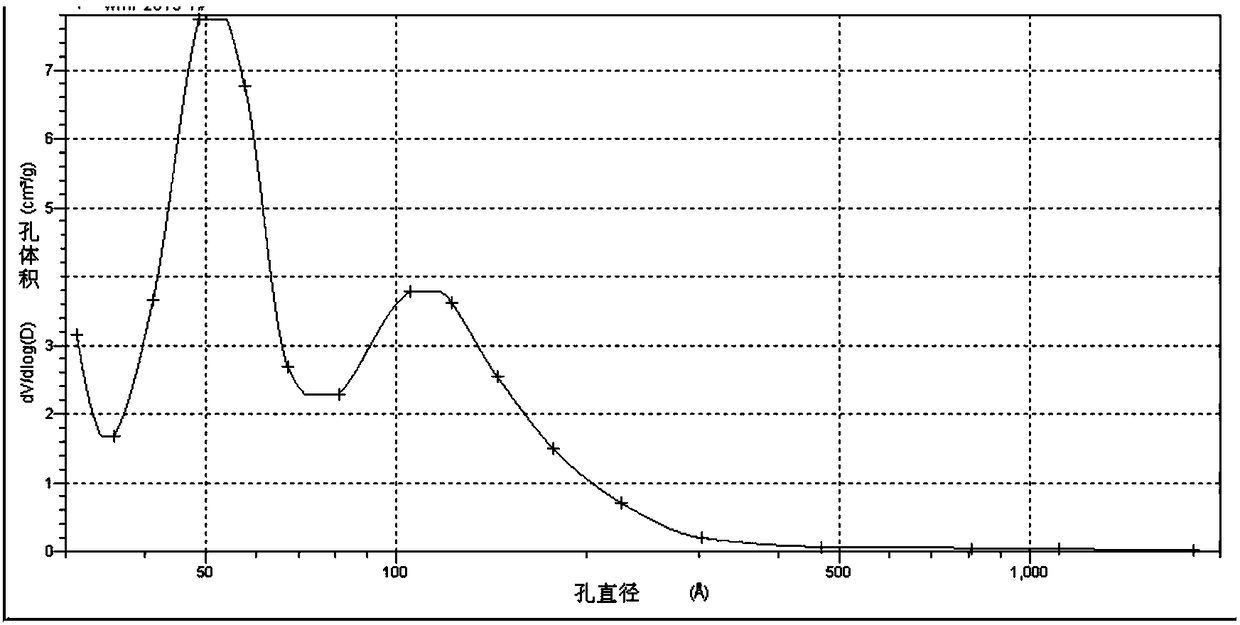

[0044] Dissolve non-ionic surfactant P123 in ethanol, stir at 35°C to dissolve completely, and form solution A; wherein the mass ratio of surfactant to ethanol is 1:5, add 0.05M hydrogen to solution A Sodium oxide solution, adjust the pH value to 8, continue to stir for 1h to form solution B; add tetraethyl orthosilicate to solution B, stir for 1h to form solution C; wherein the mass ratio of surfactant to tetraethyl orthosilicate is 1:1; add 10nm 20% silica gel solution and 20% phenolic resin solution to solution C, continue stirring for 3 hours to form solution D; wherein the mass ratio of P123 to silica gel solution is 1:1, silica gel and phenolic resin The mass ratio is 1:1; the solution D is aged at 90°C for 12h to obtain powder E; the powder E is kept at 400°C for 2h and 800°C for 2h under nitrogen gas protection to obtain powder F; the obtained powder Soak and wash with 5% hydrofluoric acid solution for 12 hours, and dry at 80°C to obtain the carbon material with gradie...

Embodiment 2

[0050] Dissolve non-ionic surfactant F127 in ethanol, stir at 40°C to dissolve completely, and form solution A; wherein the mass ratio of surfactant to ethanol is 1:5, add 1M hydroxide to solution A Sodium solution, adjust the pH value to 9, continue to stir for 1h to form solution B; add tetraethyl orthosilicate to solution B, stir for 1h to form solution C; wherein the mass ratio of surfactant to tetraethyl orthosilicate is 1 : 2; Add 20nm 40% silica gel solution and 20% phenolic resin solution in solution C, continue to stir for 3h, form solution D; Wherein the mass ratio of F127 and silica gel solution is 1:1, the ratio of silica gel and phenolic resin The mass ratio is 2:1; the solution D is aged at 100°C for 24 hours to obtain powder E; the powder E is kept at a constant temperature of 350°C for 3 hours and 900°C for 3 hours under nitrogen gas protection to obtain powder F; the obtained powder is used Soak and wash in 10% hydrofluoric acid solution for 24 hours, and dry ...

Embodiment 3

[0060] Dissolve non-ionic surfactant P123 in isopropanol, stir at 50°C to dissolve completely, and form solution A; wherein the mass ratio of surfactant to ethanol is 1:6, add 1M Potassium hydroxide solution, adjust the pH value to 11, continue to stir for 3 hours to form solution B; add methyl orthosilicate to solution B, stir for 3 hours to form solution C; wherein the mass ratio of surfactant to ethyl orthosilicate 1:3; add 30nm 40% silica gel solution and 40% phenolic resin solution to solution C, and continue to stir for 6 hours to form solution D; wherein the mass ratio of P123 to silica gel solution is 1:3, silica gel and phenolic resin The mass ratio of the solution D is 4:1; the solution D is aged at 150°C for 72h to obtain the powder E; the powder E is kept at a constant temperature of 350°C for 5h and 1000°C for 5h under the protection of nitrogen gas to obtain the powder F; the obtained powder Soak and wash in 1M sodium hydroxide solution at 80°C for 12 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com