Preparation method of laminated solar battery, and structure of lamination solar battery

A technology for solar cells and tandem cells, applied in the field of solar cells, can solve the problems that the conversion efficiency of cells cannot be further improved, and the sunlight cannot be fully utilized, and achieve the effects of improving the conversion efficiency of cells and broadening the absorption wavelength range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

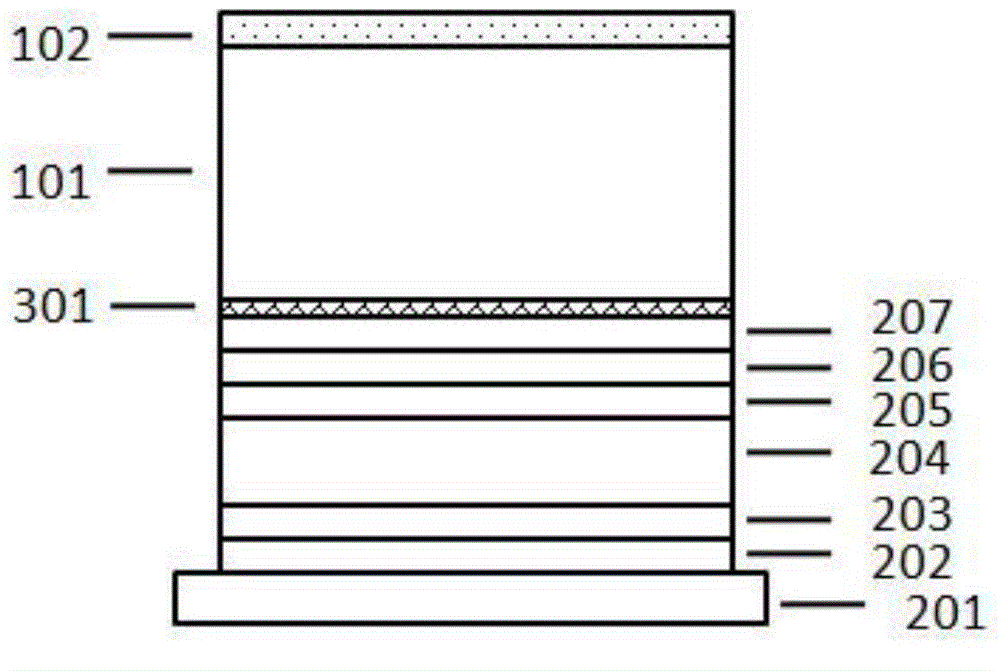

[0064] The monocrystalline silicon / copper indium gallium selenium tandem solar cell is prepared by lift-off technology. The specific preparation process is as follows:

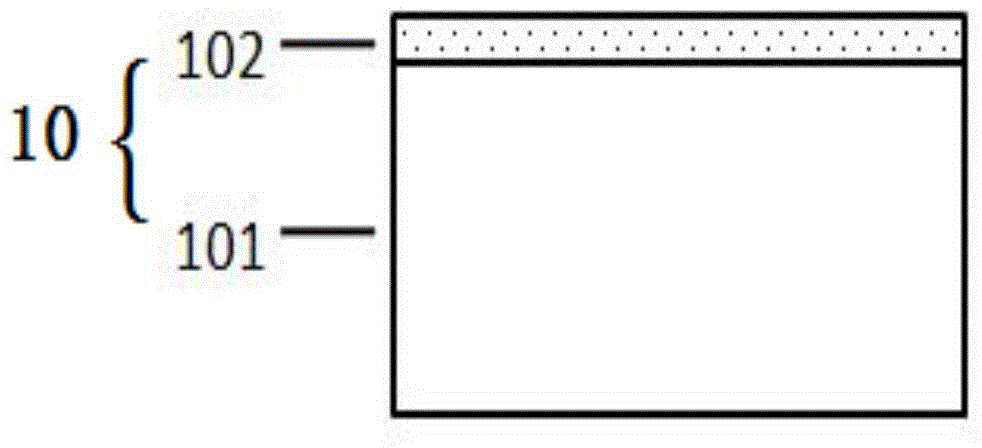

[0065] Step 1, using P-type monocrystalline silicon wafers to prepare monocrystalline silicon cells, such as figure 1 Shown:

[0066] (1) Cleaning: Use acetone solution to remove dust, metal chips, grease, etc. contaminated on the silicon wafer, and then use NaOH solution to remove the damaged layer on the surface of the silicon wafer. The thickness of the damaged layer is 30-50 μm.

[0067] (2) Fabrication of the textured surface: Anisotropic etching was carried out on the silicon wafer with NaOH dilute solution with a concentration of about 1%, and the etching temperature was 80° C., and the textured surface was prepared on the surface of the silicon wafer.

[0068] (3) Phosphorus diffusion: use N at a high temperature of 850°C 2 POCI 3 Bring it into the reaction vessel for phosphorus diffusion to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com