A high-speed lubrication performance testing machine for pre-repairing friction pairs and its application

A lubrication performance and friction pair technology, applied in the field of high-speed lubrication performance testing machines, can solve the problems of difficulty in meeting high-speed friction test requirements, affecting test accuracy and accuracy, and harsh conditions in the running-in process, so as to achieve high-speed lubrication performance testing, Ensure the relative motion accuracy and reduce the effect of the running-in process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

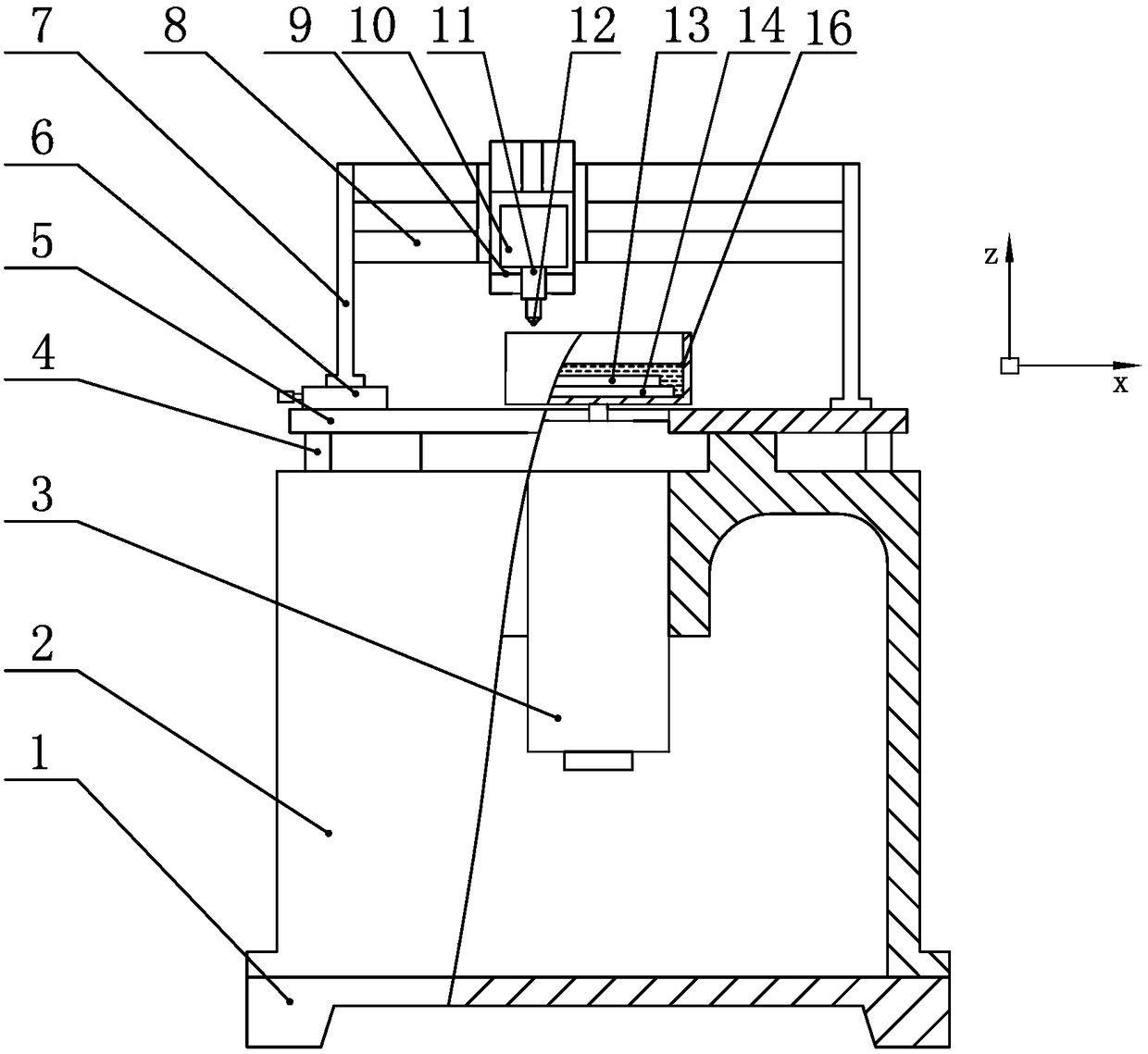

[0060] Please check Figure 1 to Figure 5 , a high-speed lubrication performance testing machine for pre-repairing friction pairs, including:

[0061] The fixed seat includes the bed 2 and the base 1 arranged up and down and fixed with bolts; the bed 2 is a cast iron structure, which can ensure the overall rigidity of the testing machine and has a certain vibration absorption capacity;

[0062] The horizontally arranged workbench 5 is fixed on the top of the bed 2; an adjustment device is provided between the workbench 5 and the bed 2, which is an adjustment screw 4 for leveling the workbench 5 and exerting a certain force on the workbench 5. Supporting function to increase the rigidity of the workbench 5; the middle part of the workbench 5 is a hole structure;

[0063] The vertically arranged electric spindle 3 is fixed on the bed 2, and the electric spindle 3 penetrates the worktable 5 upwards from the hole structure of the worktable 5; The speed change device drives the m...

Embodiment 2

[0084] Utilize the high-speed lubrication performance testing machine of the pre-repaired friction pair of the embodiment of the present invention 1 to carry out concrete test:

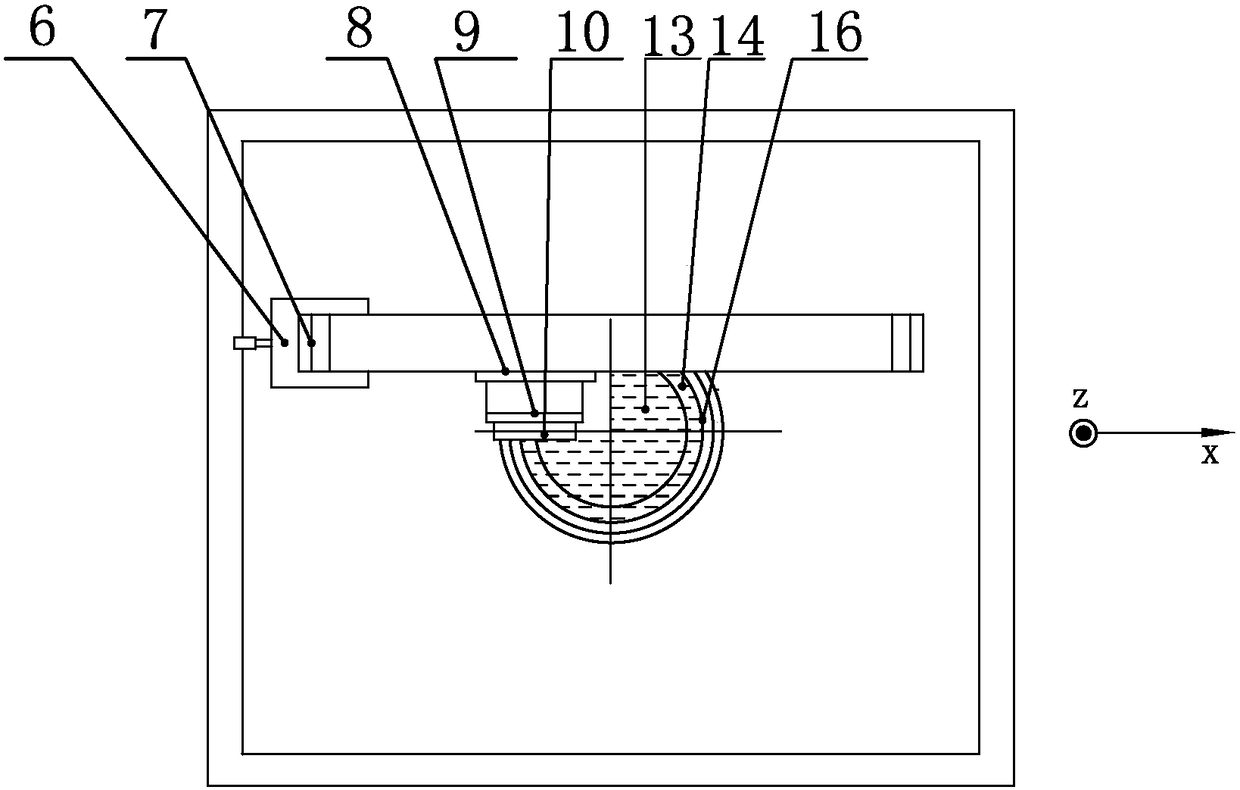

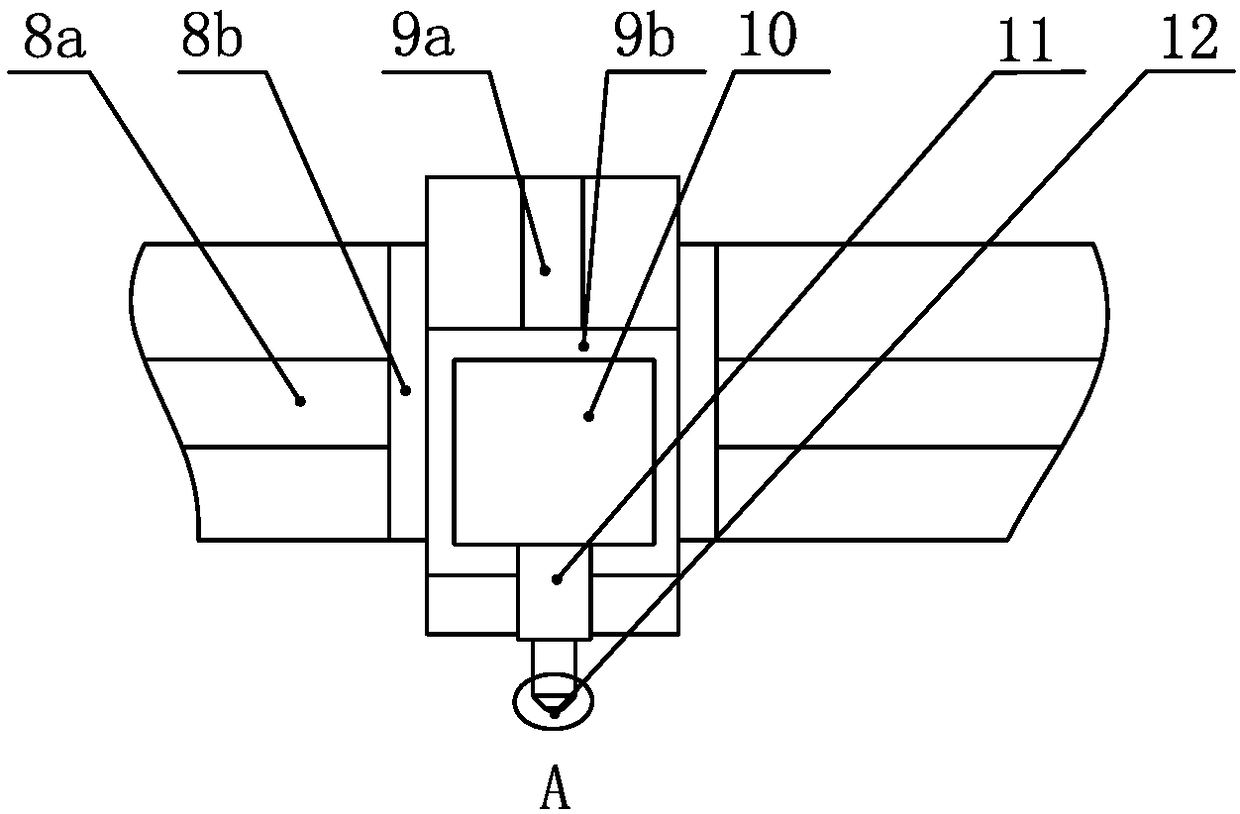

[0085] 1) Fix an oxygen-free copper disc-shaped friction disc 13 with a diameter of 400 mm in the center of the bottom of the splash-proof box 16, and the splash-proof box 16 is fixed on the electric spindle 3, and the friction disc 13 can be rotated by the electric spindle 3; use a dynamic balancer The friction disc 13 and the anti-splash box 16 are dynamically balanced on-line as a whole to reduce the vibration of the friction disc 13 and the anti-splash box 16 during high-speed rotation, thereby ensuring that the grinding tool 12 and the friction disc 13 can be stably touch;

[0086] 2) The electric spindle 3 drives the friction disc 13 to rotate, and the disc repair tool 15b is a diamond turning tool, which is driven by the Z-direction linear motor 9 with a certain depth of cut and driven by the X...

Embodiment 3

[0093] 1) Fix the disc-shaped friction disc 13 of gear steel 42CrMoV (hardness HRC50) with a diameter of 400mm in the center of the inner bottom of the splash-proof box 16, and the splash-proof box 16 is fixed on the electric spindle 3, and the friction disc 13 can be rotated by the electric spindle 3; Use a dynamic balancer to carry out overall online dynamic balance on the friction disc 13 and the anti-splash box 16 to reduce the vibration of the friction disc 13 and the anti-splash box 16 during high-speed rotation, so as to ensure the grinding tool 12 and the friction disc during the scratching process 13 can be stably contacted;

[0094] 2) The electric spindle 3 drives the friction disc 13 to rotate, and the disc repairing tool 15b is a CBN (cubic boron nitride) turning tool, driven by the Z-direction linear motor 9 with a certain depth of cut and driven by the X-direction linear motor 8 along the friction disc. 13 radial feed, cutting into the friction disc 13 radially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com