Construction equipment and application of reinforced skeleton of tunnel second lining

A steel skeleton and tunnel technology, applied in tunnel lining, tunnel, shaft equipment, etc., can solve the problems of labor-intensive manual lifting, time-consuming, and limited operating space, so as to achieve sufficient and safe operating space, reduce construction costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

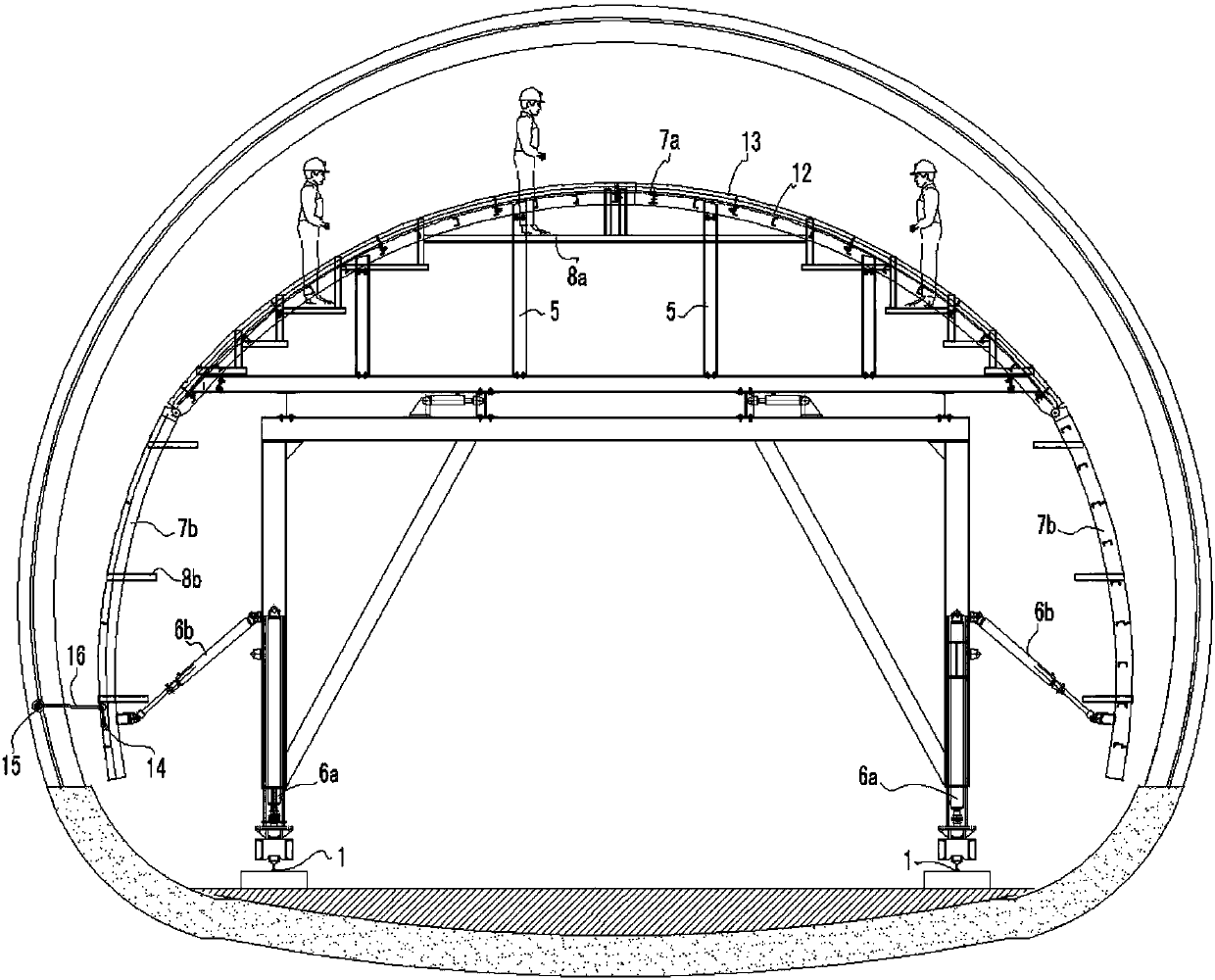

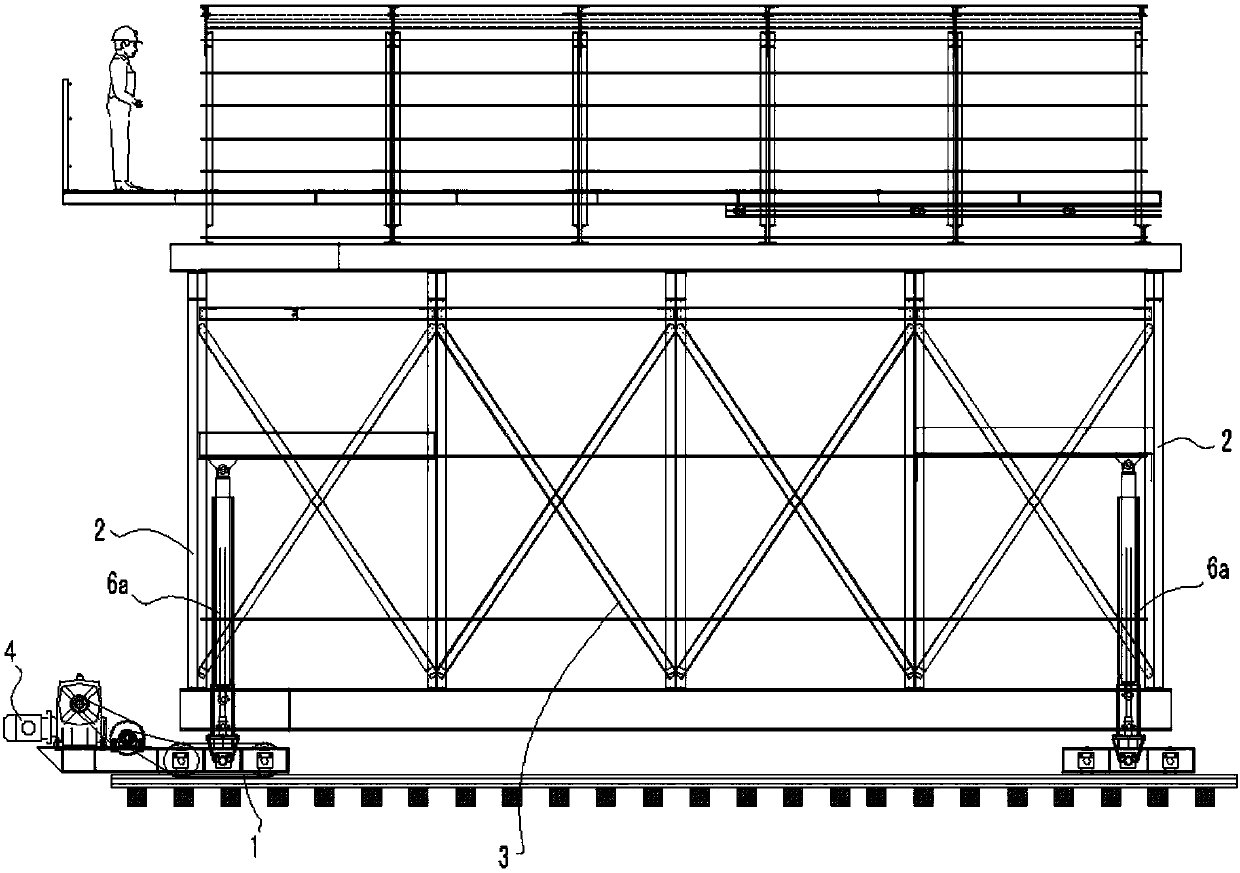

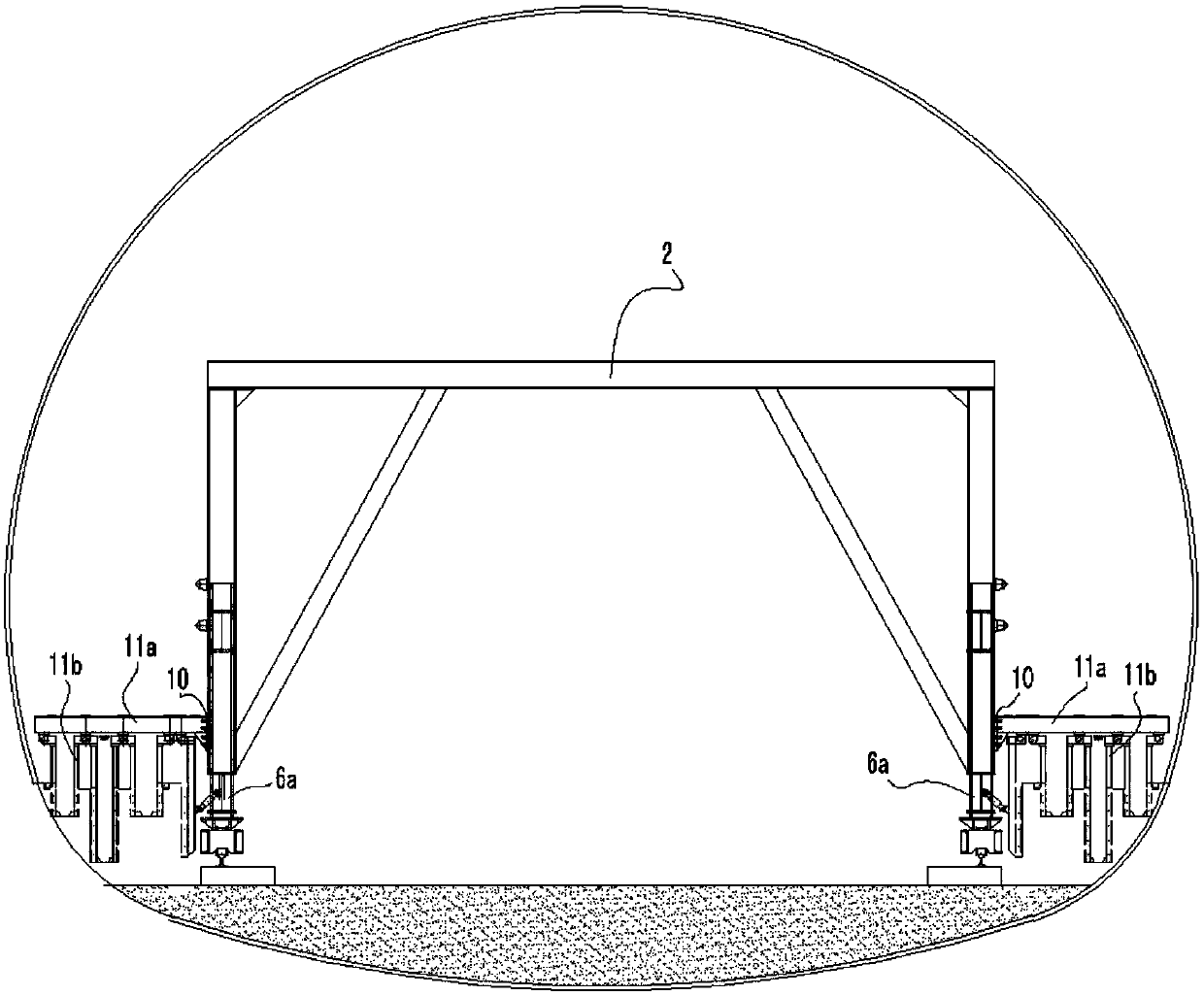

[0044] see figure 1 , figure 2 and image 3 , the structural form of the construction equipment for the second lining of the tunnel reinforced skeleton in this embodiment is:

[0045] The trolley track 1 is set to be two parallel steel rails that are auxiliary arranged in the tunnel along the direction of the tunnel.

[0046]The setting platform frame is composed of two front and rear "door" steel frames 2 and a "door" shaped truss 3 arranged between the front and rear two "door" steel frames 2; the "door" steel frame 2 and the "door" The "type trusses 3 are respectively composed of steel frame top beams and columns on both sides, and the trolley frame is supported on the trolley track 2 by using the casters at the bottom of the columns on both sides of the two "door" steel frames 2 at the front and rear, and Driven by the motor 4, it can move along the trolley track 1 to realize mechanized movement and improve construction efficiency.

[0047] At the bottom of the column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com