Plastic product processing line

A processing line and product technology, which is applied in the field of plastic product processing lines, can solve problems such as low production efficiency and worker burns, and achieve the effect of improving production efficiency and avoiding burns to workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

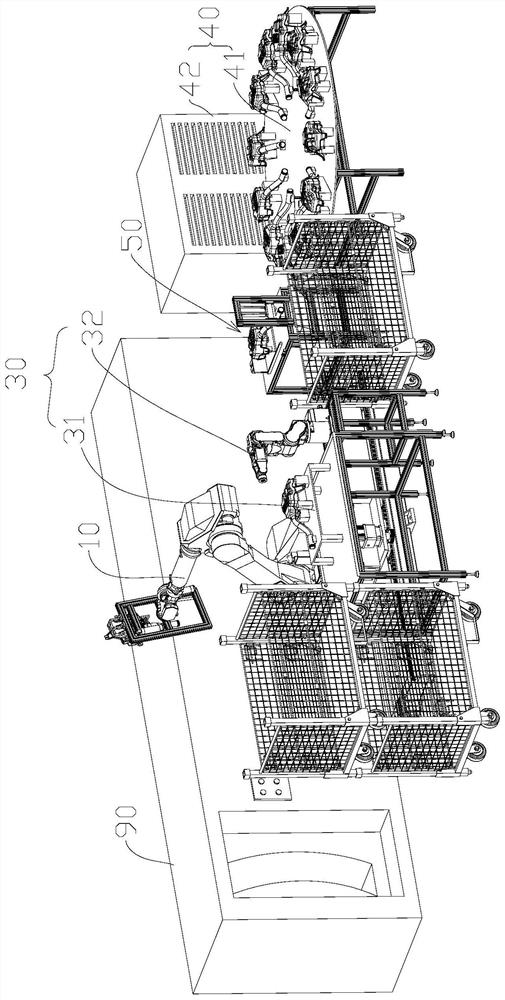

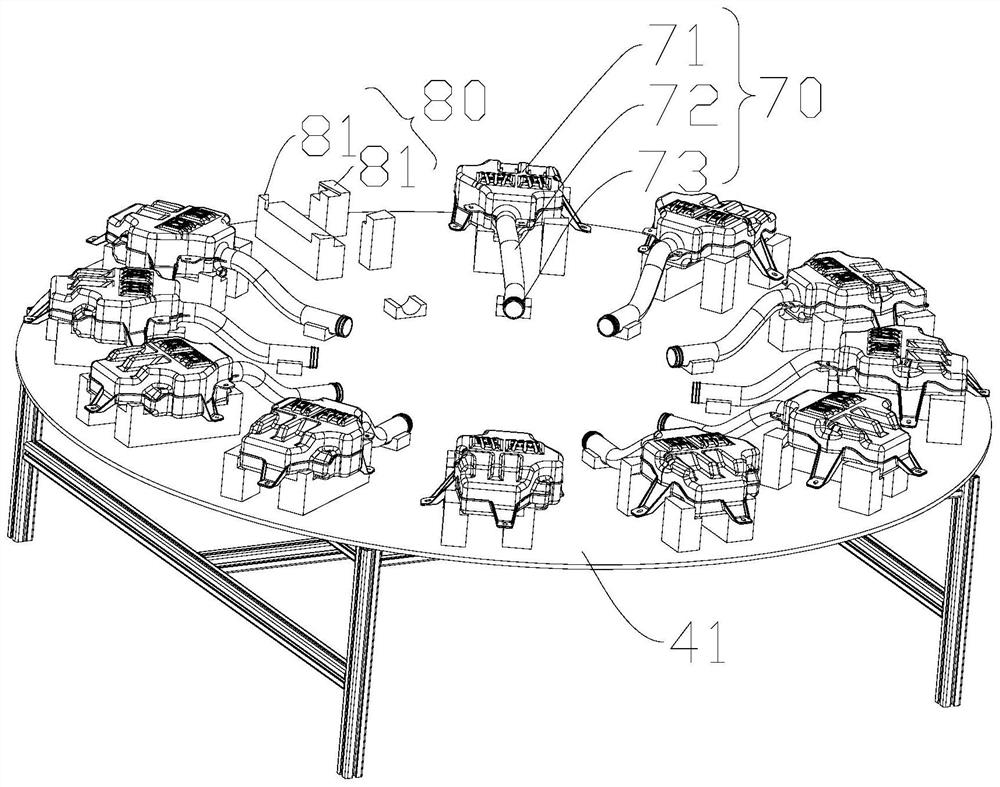

[0025] see Figure 1 to Figure 3 As shown, a plastic product processing line includes a handling device 10, a trimming device 30, a cooling device 40 and a nozzle shearing device 50; wherein,

[0026] The handling device 10 is used to sequentially transfer the plastic product 70 to the trimming device 30, the nozzle shearing device 50 and the cooling device 40; specifically, the handling device 10 takes out the plastic product 70 of the external injection molding machine 20, and sequentially transfers it to the trimming device 30. In the nozzle shearing device 50 and the cooling device 40; the above-mentioned handling device 10 can use a handling manipulator;

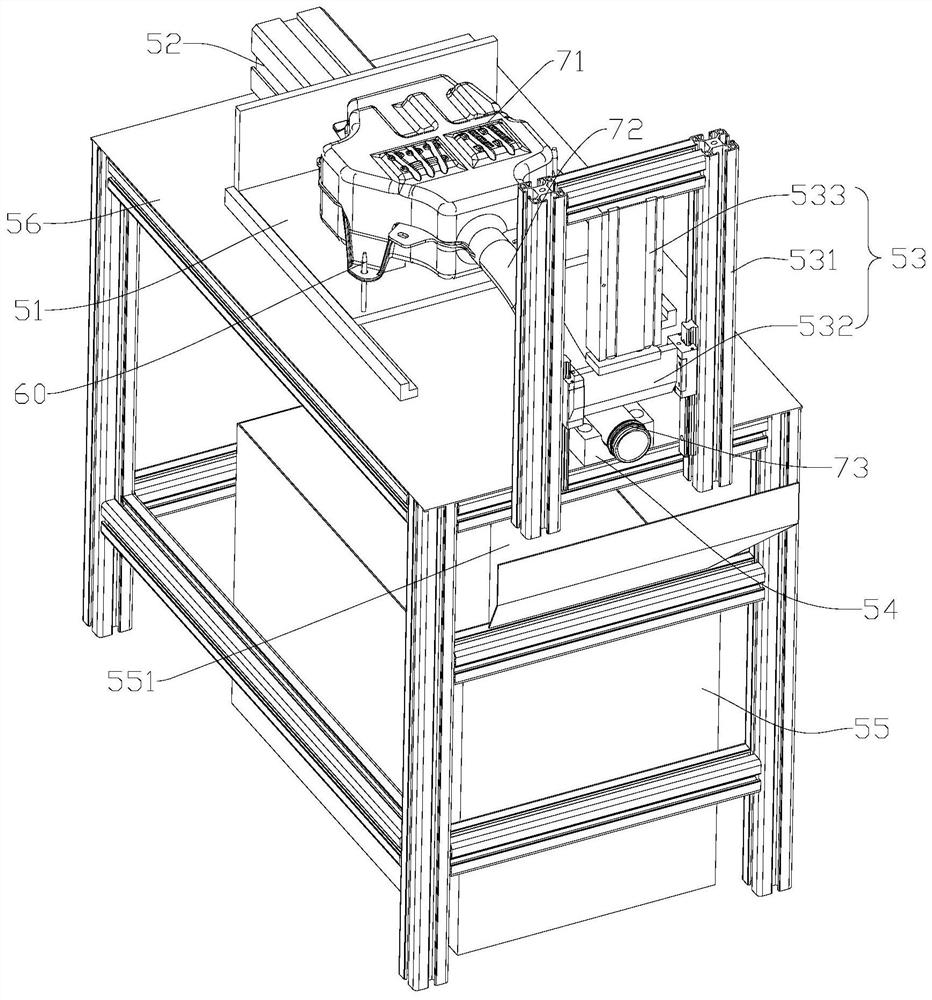

[0027] The nozzle shearing device 50 is used to cut off the nozzle 73 of the plastic product;

[0028] The trimming device 30 is used to trim the plastic product 70; specifically, the trimming device 30 includes a trimming manipulator 32, a tool and a processing table 31 installed on the trimming manipulator 32; The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com