Bridge bottom operation vehicle special for row-type pier continuous beam bridge and convenient to inspect and construct

A working vehicle, a convenient technology, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of time-consuming, labor-intensive, costly, etc., and achieve the effect of expanding the operating range, reducing shaking, and large volume and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

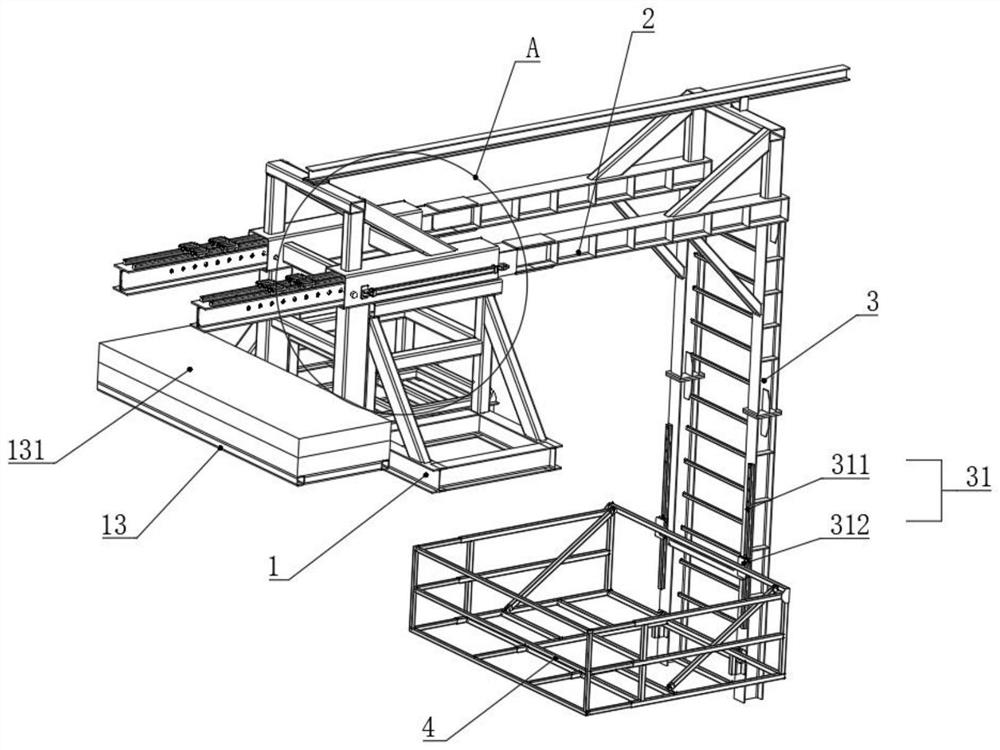

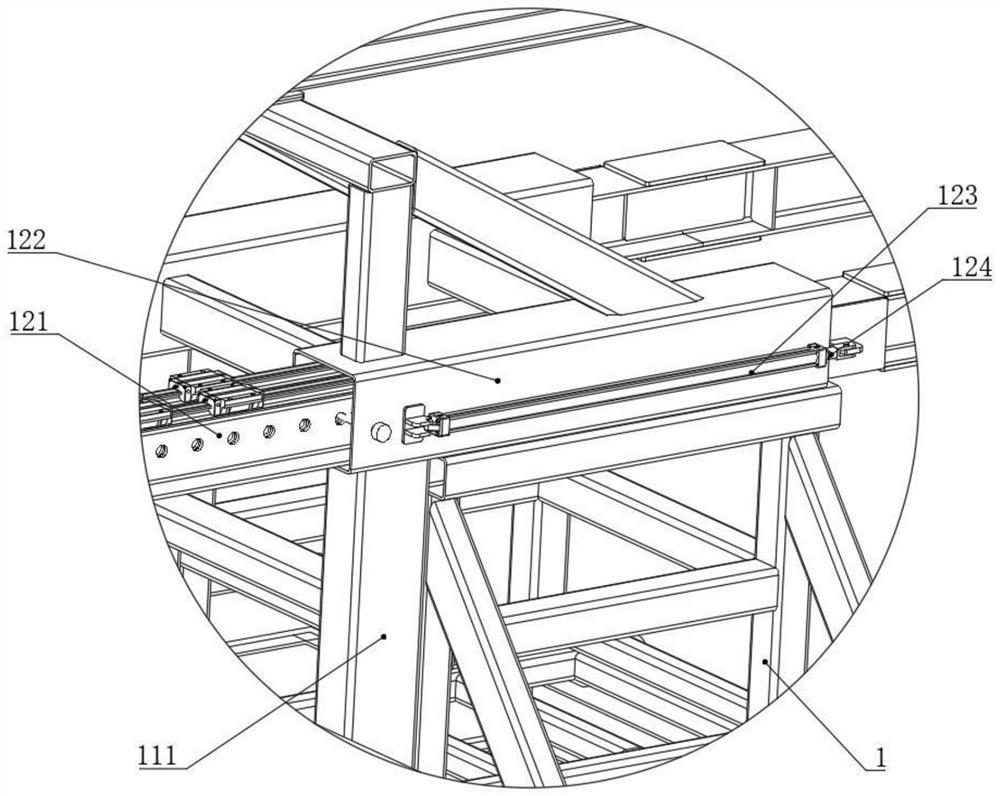

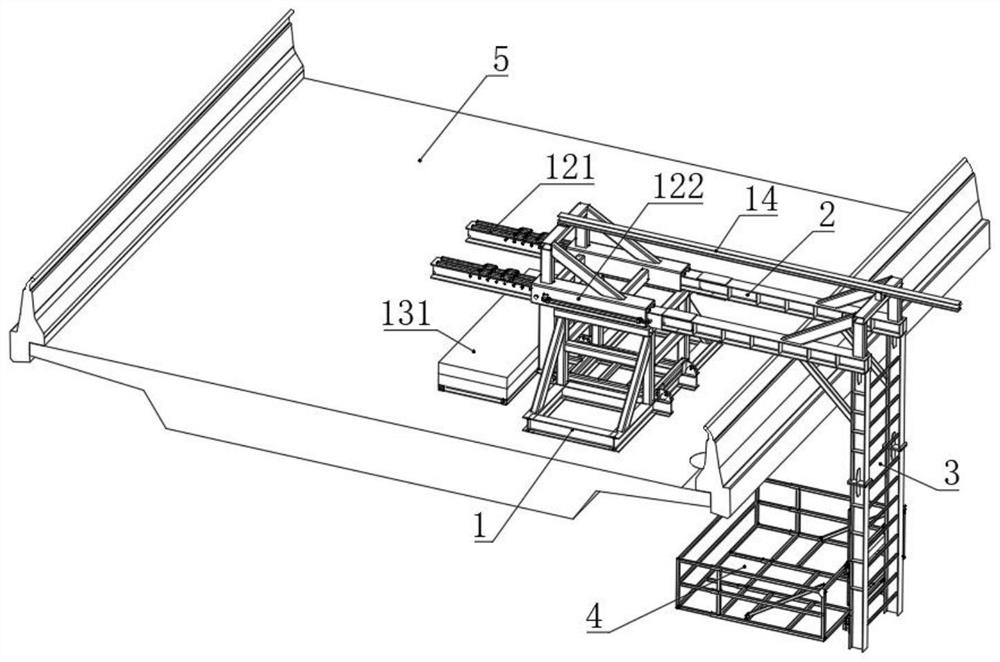

[0038] like Figure 1-Figure 5 As shown, a special bridge bottom operation vehicle for row-type pier continuous girder bridges of the present invention, which is convenient for inspection and construction, includes a bottom frame 1 and an operating frame installed on the bottom frame 1. The shape of the operating frame is a "horizontal folding hook" shape;

[0039] The operating frame includes a horizontal support 2, a vertical support 3 and a working platform 4. The left end of the horizontal support 2 is installed on the bottom frame 1, the upper end of the vertical support 3 is fixed to the right end of the horizontal support 2, and the working platform 4 is installed on the vertical support 3. bottom left of the .

[0040] When the work vehicle is in use, the bottom frame 1 is on the deck of the bridge, the working platform 4 is below the bridge, workers and installation materials are placed on the working platform 4, and the work is carried out below the bridge. The stru...

Embodiment 2

[0054] This embodiment is a further improvement of the previous embodiment, such as Figure 1-Figure 5 As shown, a special bridge bottom operation vehicle for row-type pier continuous girder bridges of the present invention, which is convenient for inspection and construction, includes a bottom frame 1 and an operating frame installed on the bottom frame 1. The shape of the operating frame is a "horizontal folding hook" shape;

[0055] The operating frame includes a horizontal support 2, a vertical support 3 and a working platform 4. The left end of the horizontal support 2 is installed on the bottom frame 1, the upper end of the vertical support 3 is fixed to the right end of the horizontal support 2, and the working platform 4 is installed on the vertical support 3. bottom left of the .

[0056] When the work vehicle is in use, the bottom frame 1 is on the deck of the bridge, the working platform 4 is below the bridge, workers and installation materials are placed on the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com