Dye mixing and toning integrated device for graphic design

A graphic design, dye technology, applied in mixers, shake/oscillation/vibration mixers, transportation and packaging, etc., can solve the problems of cumbersome mixing and color matching, inconvenient use, etc., and achieve the effect of improving work efficiency and mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

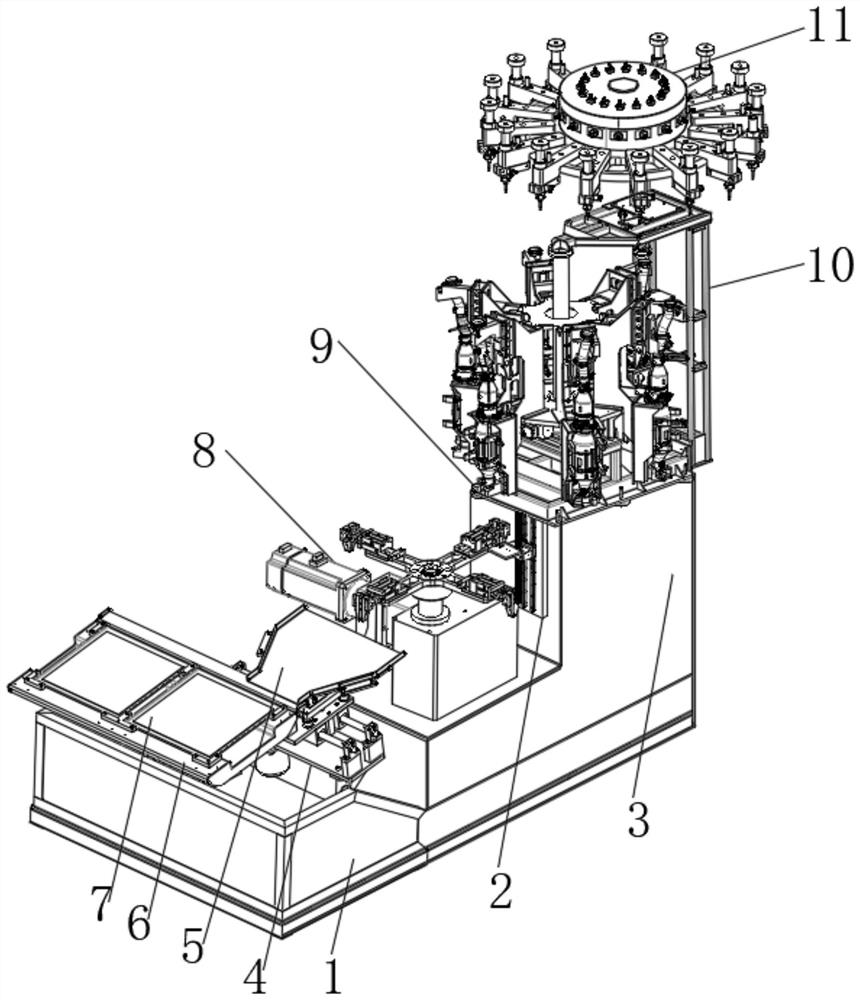

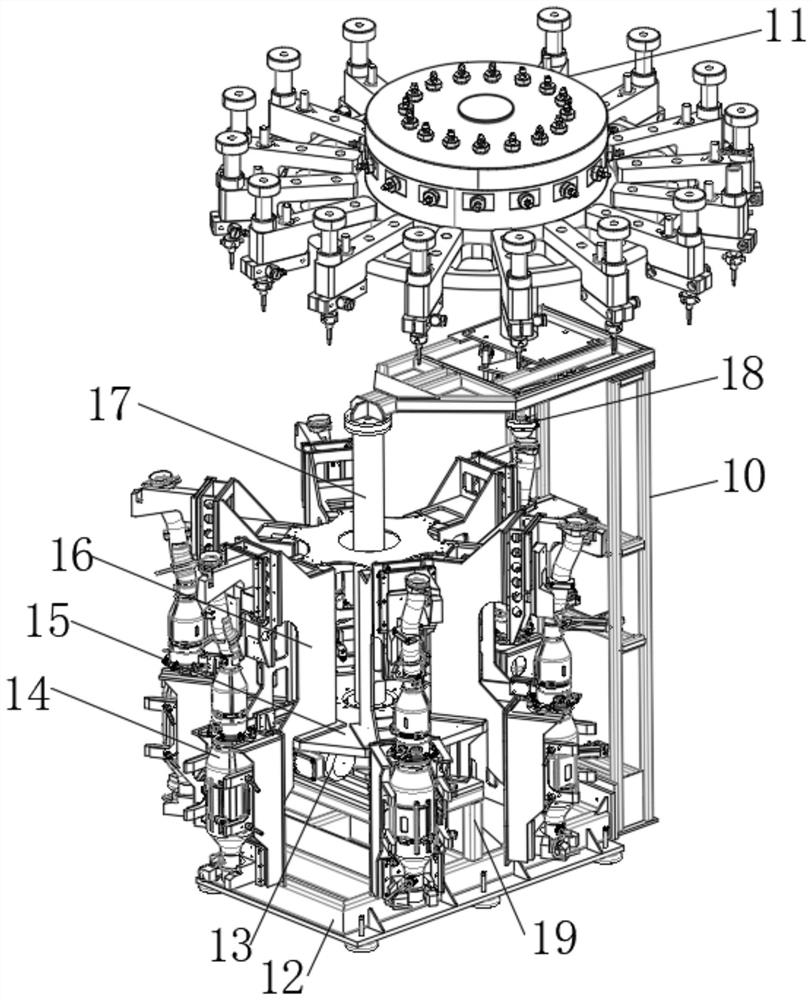

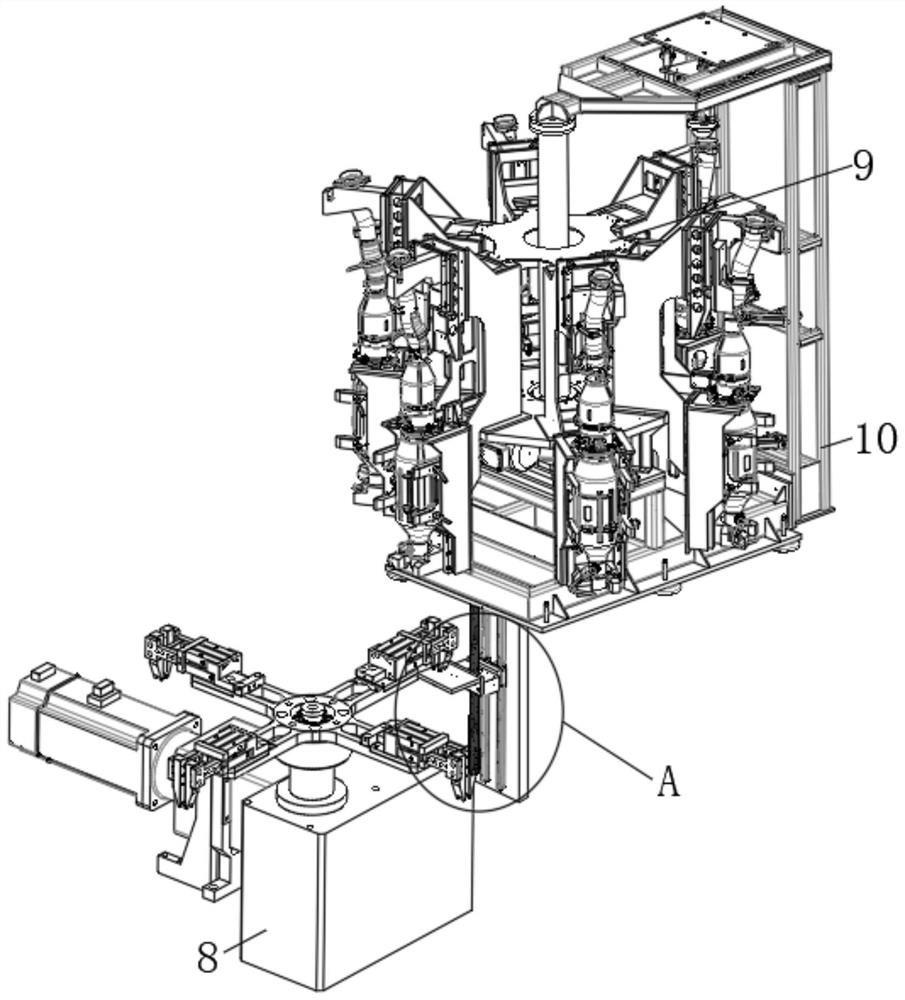

[0034] see Figure 1-9 , the preferred embodiment of the present invention provides an integrated dye mixing and coloring device for graphic design, including a base 1, an L-shaped seat 3 is fixedly installed on one side of the base 1, and the concave part of the L-shaped seat 3 is fixedly installed with a rotating Sandwich structure 8. The both sides of the convex part of L-shaped seat 3 are fixedly installed with mixing structure 9 and frame 10 respectively, and the top of frame 10 is provided with feeding structure 11, and L-shaped seat 3 is provided with receiving structure 2, and base 1 The top of the base 1 and the side away from the L-shaped seat 3 are fixedly installed with a placement shelf plate 6, and the top of the placement shelf plate 6 is equidistant and fixedly installed with a number of design placement plates 7, and the top of the base 1 is located near the L-shaped seat 3 One side of the carrier disc displacement structure 4 is fixedly installed, and the lo...

Embodiment 2

[0039] In a preferred embodiment, the rotating clamping structure 8 includes a box body 35 , the box body 35 is rotatably mounted with a rotating column 36 through a bearing inlaid on the top of the box body 35 , and a cross-shaped rotating seat 37 is fixedly installed at the top of the rotating column 36 . The top of the cross-shaped rotating base 37 is fixedly equipped with four electric telescopic rods two 38, and the movable end of the electric telescopic rod two 38 is fixedly connected with a rectangular plate 39, and one side of the rectangular plate 39 is fixedly equipped with a clamp head 40. A motor is fixedly installed at the bottom of the rotating post 36 , and the motor is fixedly installed inside the box body 35 . The placement shelf plate 6 includes two electric push rods, and the movable end of the electric push rods is fixedly connected with a clamping plate. The carrier plate displacement structure 4 includes two L-shaped frames 48, and the top of the L-shaped ...

Embodiment 3

[0041] In a preferred embodiment, the top of the mounting bracket 30 is provided with a tray support 31, and the tray support 31 is fixedly connected to the tray 5, and the bottom of the horizontally placed plate 26 is fixedly installed with a drive motor 2 50, and the drive motor 2 50 The driving end is fixedly connected with a rotating disk frame 52, and the top of the rotating disk frame 52 is fixedly equipped with a rotating short axis 51, and the horizontal plate 28 is installed with a push-pull rod 25 for rotation between the long axis and the rotating short axis 51 at the bottom, and the mounting bracket 30 is connected by hinge rotation between the tray support 31, and the top of the horizontal plate 28 is fixedly equipped with an electric telescopic link-32, and the top of the electric telescopic link-32 is hingedly connected with the bottom of the tray support 31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com