Linear steel component

A technology of steel components and glyphs, applied to building components, building structures, walls, etc., can solve the problems of poor concrete integrity, large steel consumption, and large welding workload, so as to improve bearing capacity, reduce steel consumption, The effect of improving component performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The in-line steel member of the present invention will be described in detail below with reference to the drawings and embodiments.

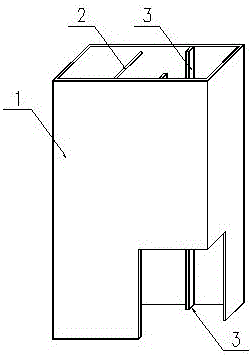

[0030] An embodiment of the inline steel member proposed by the present invention, such as figure 1 , the steel member is composed of a box-shaped steel piece 1 and a connecting piece, and the connecting piece connects the long side steel plate of the box-shaped steel piece, figure 1 In the shown embodiment, the connectors are steel rods 2; the steel bars on the long side of the box-shaped steel part 1 are provided with stiffeners 3; a row of steel rods 2 is arranged at a certain interval along the length direction of the box-shaped steel part, and each row of steel rods is arranged along the box-shaped The length direction of the steel parts is arranged at a certain interval. figure 2 In the shown embodiment, the steel plate on the long side of the box-shaped steel part 1 is provided with stiffening ribs 3, and the steel rods 2 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com