A kind of preparation method of titanium alloy surface liquid diffusion aluminizing composite coating

A composite coating and titanium alloy technology, which is used in the preparation of aluminized coatings on metal surfaces and the preparation of liquid diffusion aluminized composite coatings on titanium alloy surfaces. Poor plasticity and other problems, to achieve the effect of not easy to peel and crack, improve the bonding force, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] test 1

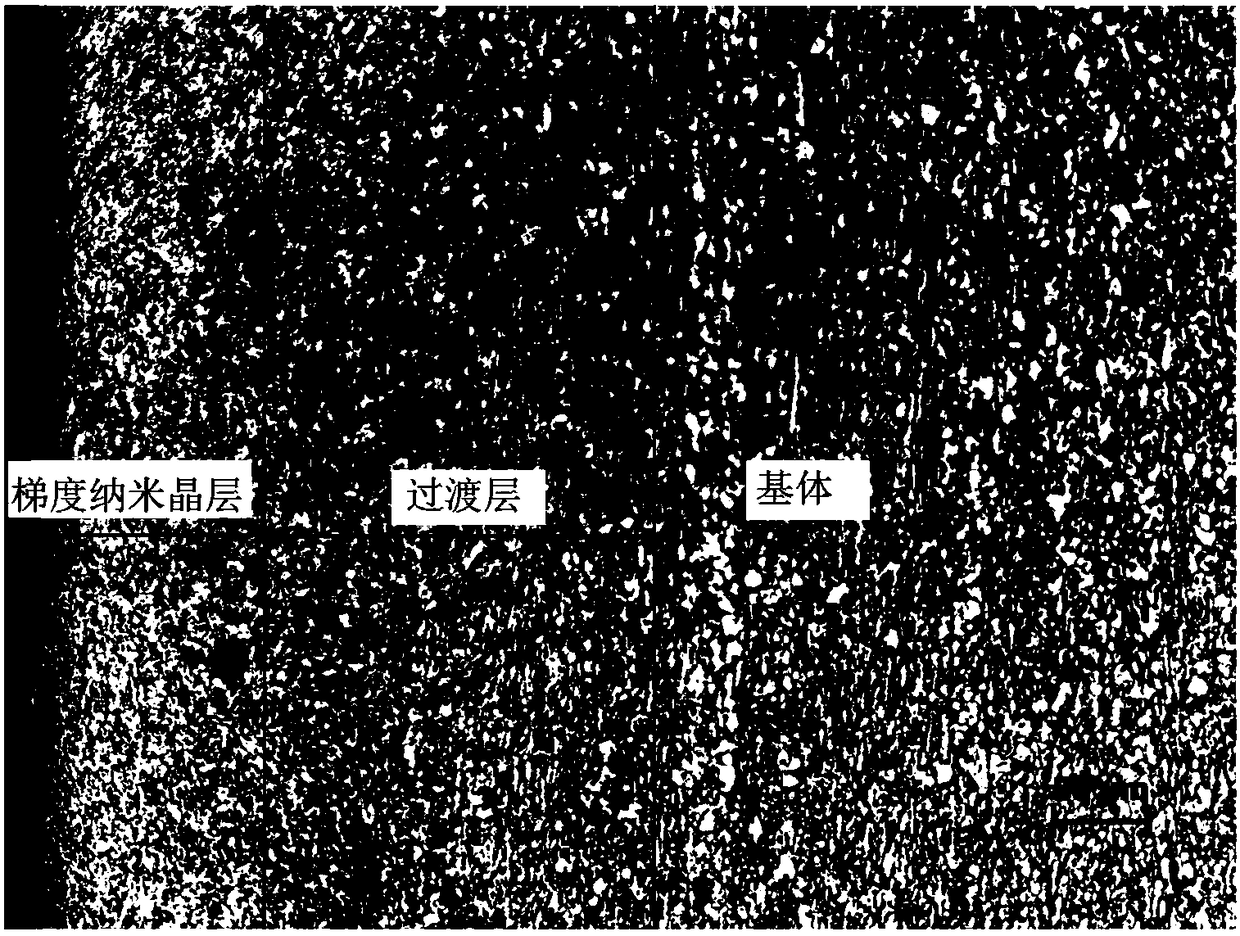

[0036] After the titanium alloy sample is polished off the surface oxide layer, it is clamped on the fixture, and the fixture is fixed on the rotary table. A hydraulic system is used to drive the indenter base so that the needle roller embedded in the indenter base is pressed into the surface of the titanium alloy sample and a pressure of 76kN is maintained on the needle roller. Power equipment is used to drive the workbench to rotate at a speed of 2r / min to drive the titanium alloy sample to rotate. The needle roller rolls on the surface of the titanium alloy sample for 30 minutes to cause strong plastic deformation on the surface of the titanium alloy sample, thereby forming gradient nanocrystals on the surface of the titanium alloy sample. Floor.

[0037] The aluminum block is polished to remove the oxide layer and ultrasonically cleaned in absolute ethanol. At the same time, the surface nanosized titanium alloy sample is ultrasonically cleaned in absolute ...

Embodiment 2

[0046] test 1

[0047] The process flow and other process parameters of Experiment 1 of this embodiment are the same as those of Experiment 1 of Example 1, except that the time of aluminum expansion in the treatment of liquid aluminum expansion is 1.5 h.

[0048] test 2

[0049] The process flow and other process parameters of Experiment 2 of this embodiment are the same as those of Experiment 2 of Example 1, except that the time of aluminum expansion in the treatment of liquid aluminum expansion is 1.5 h.

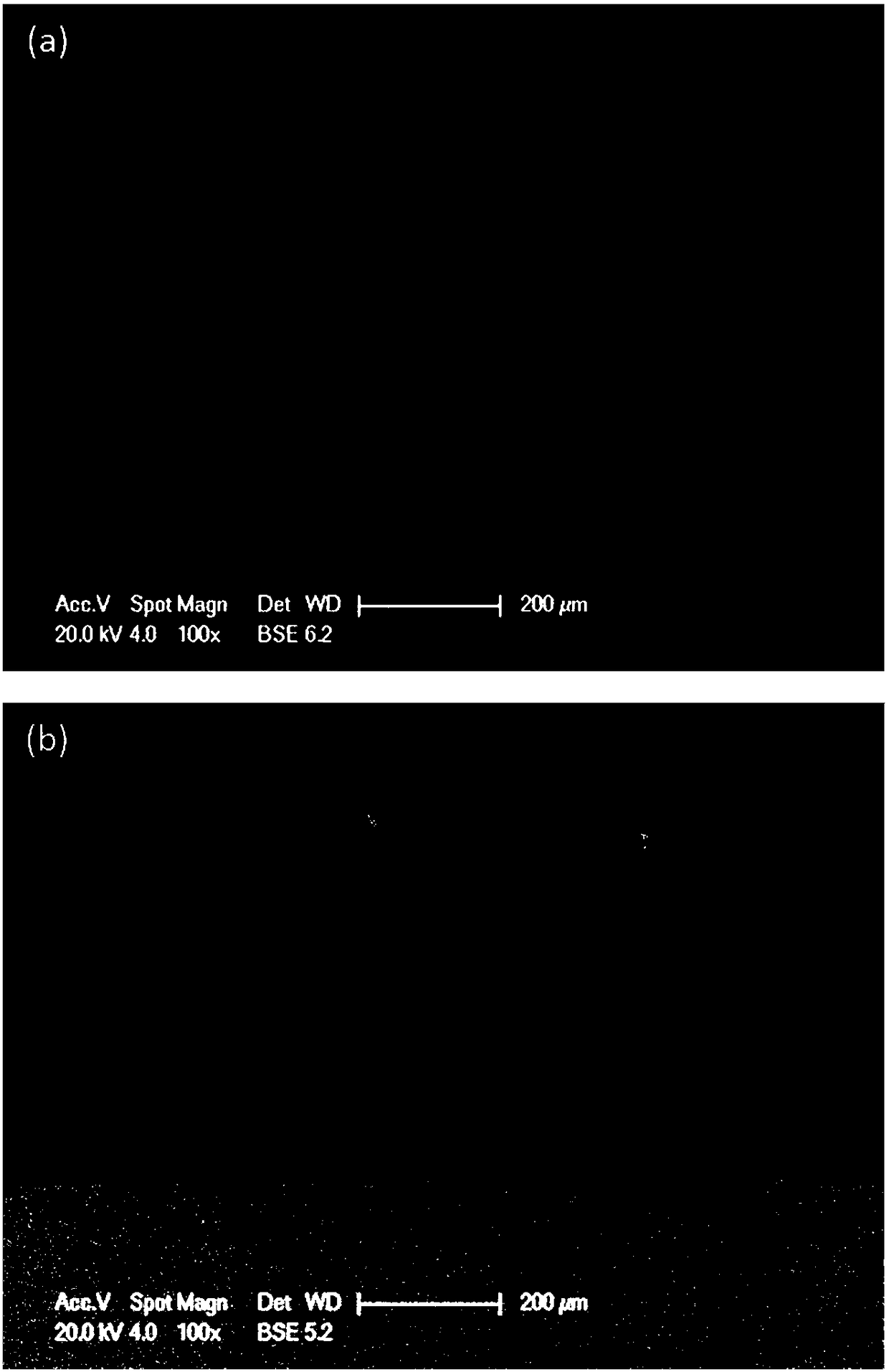

[0050] Figure 4 It is the SEM image of the titanium alloy surface coating obtained in this embodiment, wherein, Figure (a) is the SEM image of the titanium alloy surface coating obtained in Test 1, wherein it can be seen that the average thickness of the diffusion reaction layer is about 650 μm, and the maximum can reach 1000 μm. The closer the alloy matrix is, the TiAl 3 The denser the phase distribution; the farther TiAl 3 The more sparse the phase distribution, it ...

Embodiment 3

[0052] test 1

[0053] The process flow and other process parameters of Experiment 1 of this embodiment are the same as those of Experiment 1 of Example 1, except that the time of aluminum expansion in the treatment of liquid aluminum expansion is 4 hours.

[0054] test 2

[0055] The process flow and other process parameters of Experiment 2 of this embodiment are the same as those of Experiment 2 of Example 1, except that the time of aluminum expansion in the treatment of liquid aluminum expansion is 4 hours.

[0056] Figure 5 It is the SEM image of the titanium alloy surface coating obtained in this example. Figure (a) is the SEM image of the titanium alloy surface coating obtained in Test 1, where it can be seen that the average thickness of the diffusion reaction layer is about 810 μm. Figure (b) is the SEM image of the titanium alloy surface coating obtained in Experiment 2, where it can be seen that only a diffusion reaction layer about 100 μm thick is formed. In add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com