Ultra low sulfur gasoline combination production method

A production method and ultra-low sulfur technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as large loss of octane number, and achieve small loss of octane number, long operating period, high liquid the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

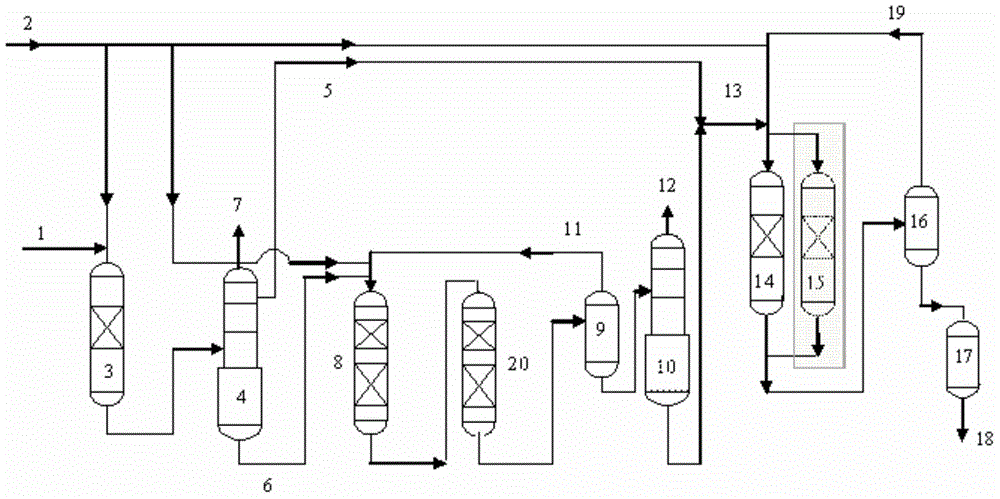

Method used

Image

Examples

Embodiment a

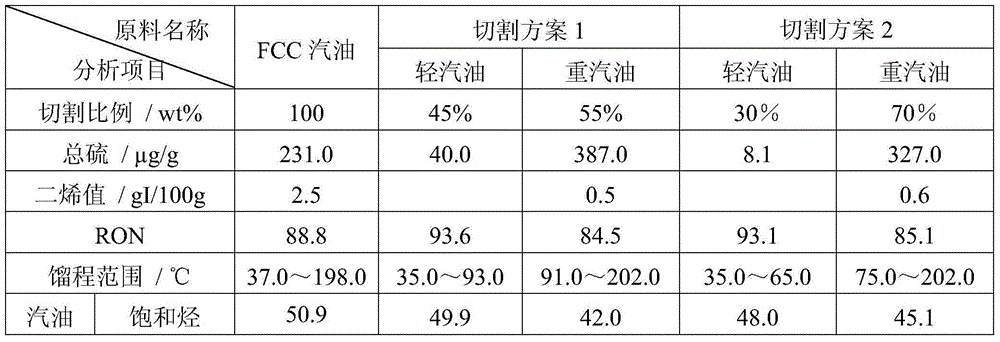

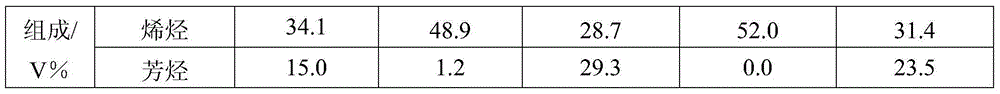

[0087] This embodiment provides a combined production method of ultra-low sulfur gasoline, including the following steps:

[0088] 1) Mix the full-cut FCC gasoline with hydrogen, enter the pre-hydrogenation reactor after preheating for pre-hydrogenation, remove part of the diolefins in the FCC gasoline feedstock, and reconstitute part of the light sulfide; The pre-hydrogenation reaction conditions are: hydrogen partial pressure 1.0MPa, volumetric space velocity 1.0h -1 , The reaction temperature is 80°C, the hydrogen-to-oil volume ratio is 1v / v, the catalyst is a pre-hydrogenation catalyst; the pre-hydrogenation catalyst is: Al 2 O 3 The monomer is the carrier, and based on 100% of the carrier weight, 4% of the VIB group element and 6% of the VIII group element are used as active components;

[0089] 2) Introduce the reaction effluent from step 1) into the fractionation tower, the top pressure of the fractionation tower is 0.7MPa, the bottom temperature is 190°C, and the top tempera...

Embodiment b

[0096] This embodiment provides a combined production method of ultra-low sulfur gasoline, including the following steps:

[0097] 1) Mix the full-cut FCC gasoline with hydrogen, enter the pre-hydrogenation reactor after preheating for pre-hydrogenation, remove part of the diolefins in the FCC gasoline feedstock, and reconstitute part of the light sulfide; The pre-hydrogenation reaction conditions are: hydrogen partial pressure 6.0MPa, volumetric space velocity 10.0h -1 , The reaction temperature is 250°C, the hydrogen-to-oil volume ratio is 100v / v, the catalyst is a pre-hydrogenation catalyst; the pre-hydrogenation catalyst is: Al 2 O 3 The monomer is the carrier, and based on 100% of the carrier weight, 10% of the VIB group element and 15% of the VIII group element are used as the active component;

[0098] 2) Introduce the reaction effluent from step 1) into the fractionation tower, the top pressure of the fractionation tower is 0.75MPa, the bottom temperature is 230°C, and the t...

Embodiment c

[0105] This embodiment provides a combined production method of ultra-low sulfur gasoline, including the following steps:

[0106] 1) Mix the full-cut FCC gasoline with hydrogen, enter the pre-hydrogenation reactor after preheating for pre-hydrogenation, remove part of the diolefins in the FCC gasoline feedstock, and reconstitute part of the light sulfide; The pre-hydrogenation reaction conditions are: hydrogen partial pressure 2.0MPa, volumetric space velocity 2.0h -1 , The reaction temperature is 80°C, the hydrogen-to-oil volume ratio is 4v / v, the catalyst is a pre-hydrogenation catalyst; the pre-hydrogenation catalyst is: Al 2 O 3 The monomer is the carrier, and based on 100% of the carrier weight, 4% of the VIB group element and 6% of the VIII group element are used as active components;

[0107] 2) Introduce the reaction effluent from step 1) into the fractionation tower, the top pressure of the fractionation tower is 0.7MPa, the bottom temperature is 190°C, and the top tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com