Narrow molecular weight distribution butyl rubber synthesis method

A narrow molecular weight distribution, butyl rubber technology, used in the field of synthetic butyl rubber, can solve the problems of low rubber vulcanization performance and low number-average absolute molecular weight of butyl rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

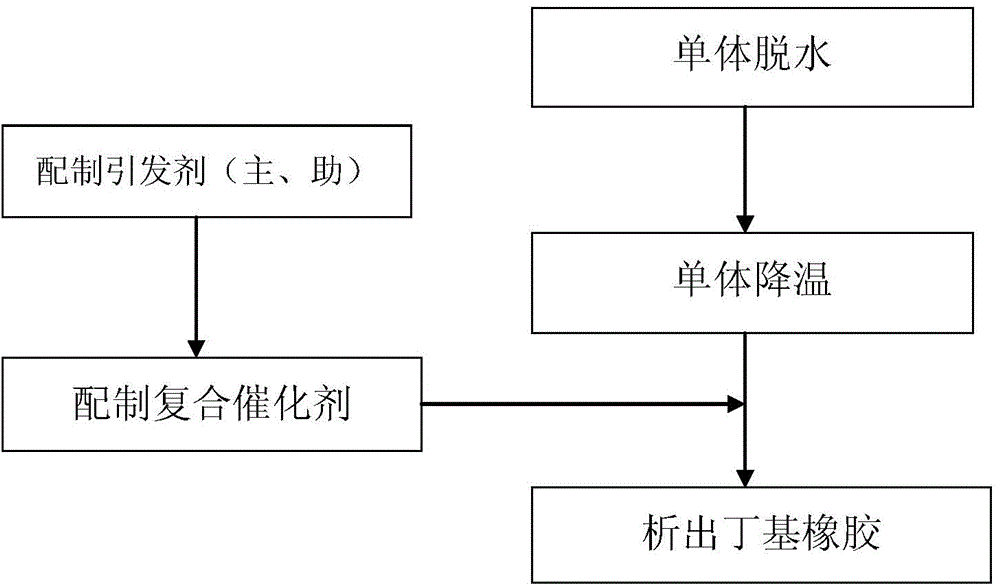

Method used

Image

Examples

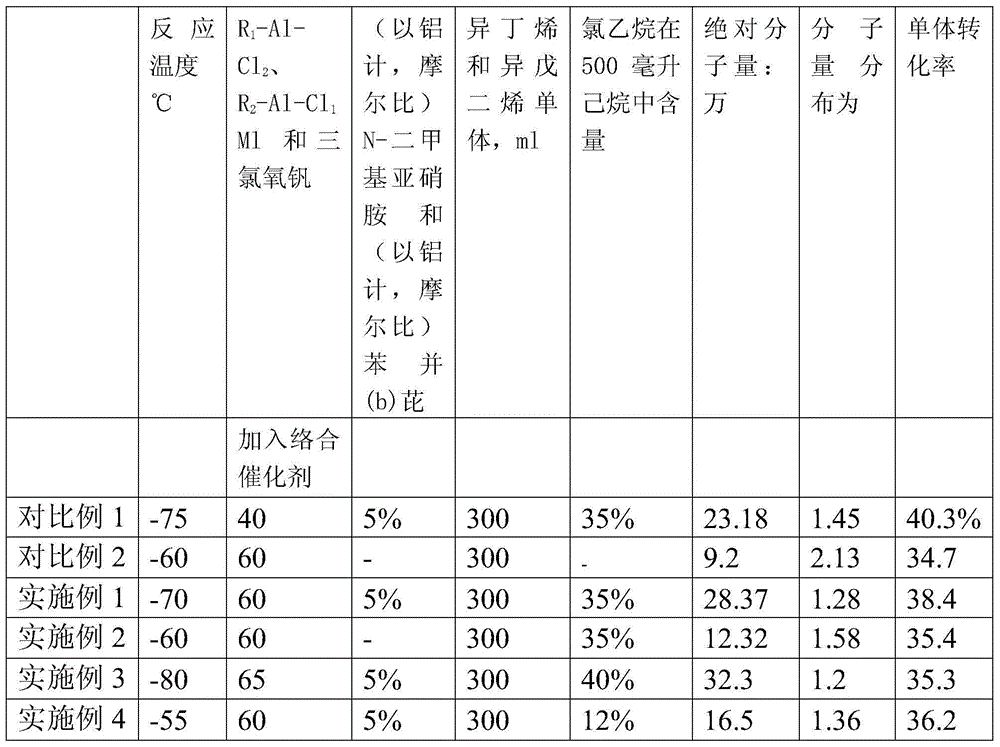

Embodiment 1

[0062] Under the protection of high-purity nitrogen, first remove the moisture in the monomer to below 10ppm, and then remove the R 1 -Al-Cl 2 , R 2 -Al-Cl 1 Mix with vanadyl trichloride in a certain molar ratio (1:1:0.5), then add a small amount of water according to the total number of moles of the catalyst (m catalyst: m water = 2:3), and then add 5% (calculated as aluminum, mole ratio) N-dimethylnitrosamine and 5% (in terms of aluminum, molar ratio) benzo(b)pyrene, prepared as a mixed initiator, mixed and aged for 5 minutes to 400 hours to form a concentration of 0.08 The complex catalyst of M (calculated as aluminum) is ready for use. After cooling 300ml of isobutylene and isoprene monomer to -70°C, mix it with 500ml of solvent (containing 35% (v) ethyl chloride), and then add 60ml The complex catalyst (concentration: 0.08M) aged for 30 minutes was reacted for 30 minutes, and 60ml of methanol was added to precipitate butyl rubber. Wash with 2% (m) NaOH aqueous solutio...

Embodiment 2

[0064] Under the protection of high-purity nitrogen, first remove the moisture in the monomer to below 10ppm, and then remove the R 1 -Al-Cl 2 , R 2 -Al-Cl 1 Mix according to a certain ratio (1:1), then add a small amount of water according to the total number of moles of the catalyst (m catalyst: m water = 2:3), mix well and age for 5 minutes to 400 hours to make a concentration of 0.08M ( The complex catalyst (calculated as aluminum) is ready for use. After 300ml of isobutylene and isoprene monomers are lowered to -60°C, they are evenly mixed with 500ml of solvent (containing 35% (v) of methyl chloride), and then added to 60ml for aging for 30 Minute complex catalyst (concentration is 0.08M), after reacting for 60 minutes, add 60ml methanol to terminate the reaction. Wash with 2% NaOH aqueous solution until alkaline, and then wash with distilled water until neutral. After drying in a vacuum oven at 60°C for 8 hours, the absolute molecular weight of butyl rubber was detec...

Embodiment 3

[0066] Under the protection of high-purity nitrogen, first remove the moisture in the monomer to below 10ppm, and then remove the R 1 -Al-Cl 2 , R 2 -Al-Cl 1 Mix with vanadyl trichloride in a certain molar ratio (2:1:0.2), then add a small amount of water according to the total number of moles of the catalyst (m catalyst: m water = 4:1), and then add 5% (calculated as aluminum, mole ratio) N-dimethylnitrosamine and 5% (in terms of aluminum, molar ratio) benzo(b)pyrene, prepared as a mixed initiator, mixed and aged for 5 minutes to 400 hours to form a concentration of 0.08 The complex catalyst of M (calculated as aluminum) is ready for use. After cooling 300ml of isobutylene and isoprene monomer to -80°C, mix it with 500ml of solvent (containing 40% (v) of methyl chloride), and then add 65ml of The complex catalyst (concentration is 0.08M) was melted for 15 minutes, and after 40 minutes of reaction, 60ml of methanol was added to precipitate butyl rubber. Wash with 2% (m) Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com