A method and device for producing sodium bicarbonate from acid gas and purifying hydrogen sulfide

A technology of sodium bicarbonate and acid gas, which is applied in the fields of hydrogen sulfide, chemical instruments and methods, alkali metal carbonates, etc., and can solve problems such as failure to realize continuous production, low purity of sulfur products, and expensive desulfurization catalysts, etc. Achieve the effects of improving product economic benefits, small equipment scale, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

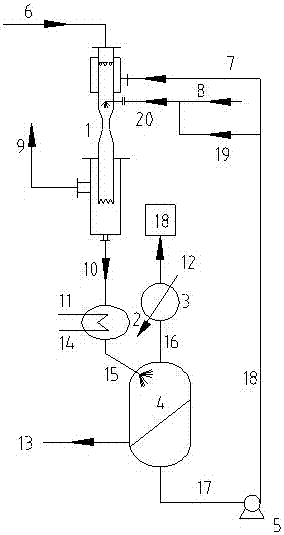

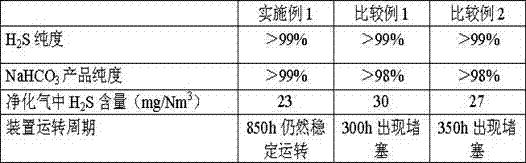

[0060] use as figure 1 The shown method and device use acid gas as raw material, sodium carbonate as absorption liquid, and sodium sulfide solution as protection liquid to carry out the reaction. CO in acid gas 2 The volume fraction is 7%, H 2 The volume fraction of S is 92%, and the volume fraction of hydrocarbons is 1%. Na 2 CO 3 The mass concentration of the solution is 20%.

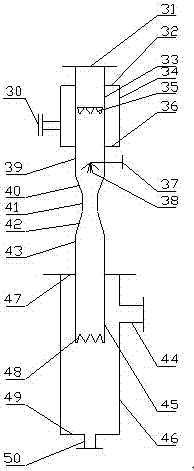

[0061] In embodiment 1, described absorption reactor adopts figure 2 The reactor shown. In embodiment 1, process solution sodium sulfide reflux part is 20% of gross weight, and the liquid-gas ratio of absorption liquid and acid gas in the absorption reactor is 5L / m 3 . The reaction temperature was controlled between 80°C and 85°C, and the reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com