Partial oxidation process burner and application thereof

An oxidation process and head technology, applied in the direction of burners, combustion methods, inorganic chemistry, etc., can solve the problems of damaged refractory bricks in the furnace, burner flange overheating, burner easy to ablate, etc., to improve the operating cycle , temperature reduction, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

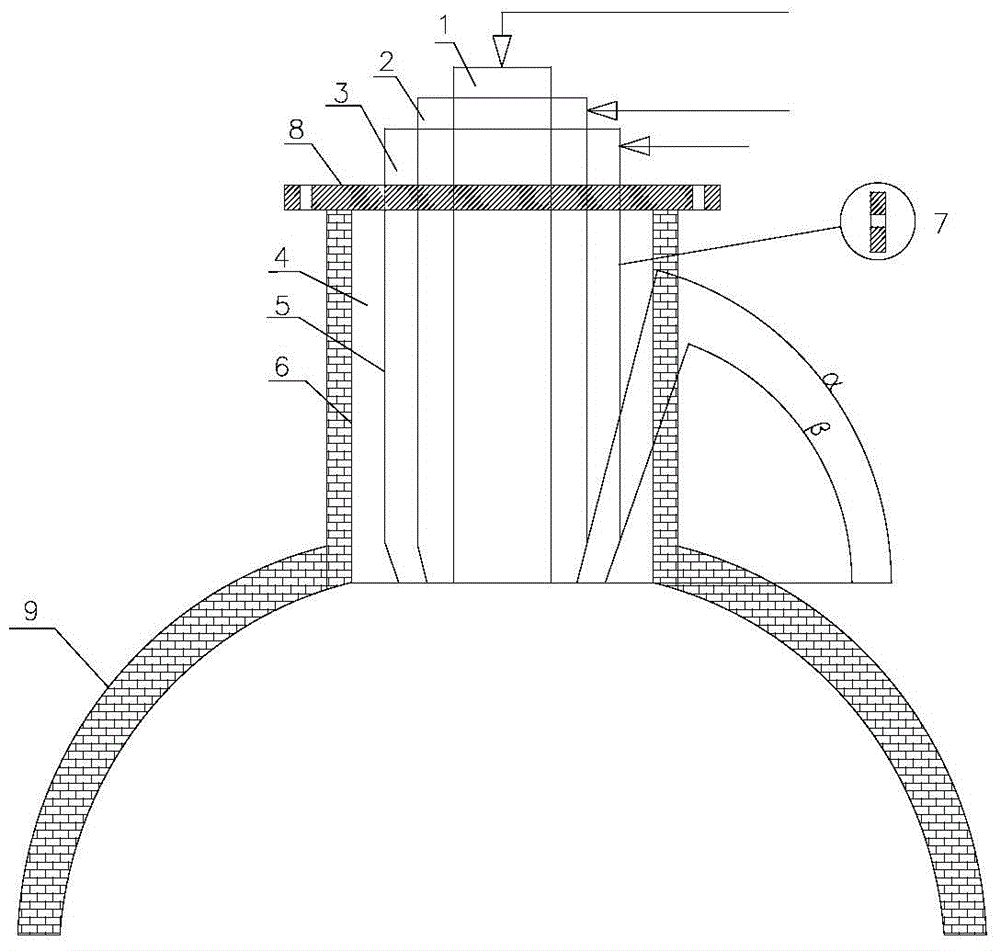

[0033] like figure 1 As shown, in this embodiment, the burner of the gaseous hydrocarbon reformer includes a gasification agent channel (1), an auxiliary gasification agent channel (2), a fuel channel (3) and a protective fuel channel arranged sequentially from the inside to the outside. The passage (4) is composed of; the head of the gasification agent passage (1) is a straight pipe structure; the external inclination angle of the head of the auxiliary gasification agent passage (2) is 75°; the fuel passage (3) The external inclination of the head is 70°. The number of holes on the outer wall (5) of the fuel channel (3) is 4, the diameter of the holes is 4 mm, and the angle between the axis of the holes and the outer wall (5) is 90°.

[0034] In this embodiment, the gasification agent pure oxygen enters the furnace through the gasification agent channel (1); the gasification agent water vapor enters the furnace through the auxiliary gasification agent channel (2). Gaseous h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com