Novel electric chuck device based on PLC control device

A control device and electric chuck technology, applied in the direction of chucks, etc., can solve the problems of low degree of automation, low machining accuracy, low operation efficiency, etc., and achieve the effects of reducing labor costs, improving clamping accuracy, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

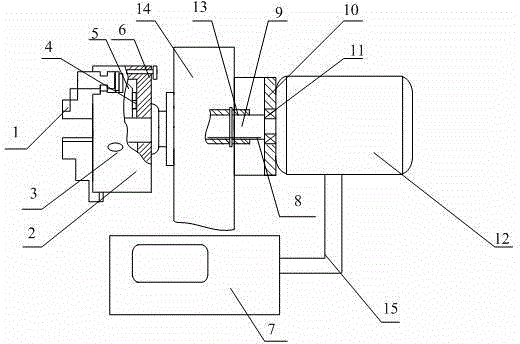

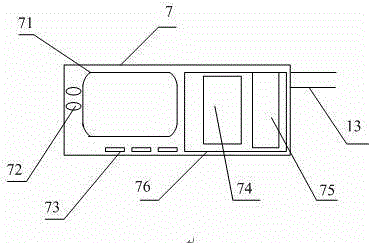

[0021] As attached figure 1 And figure 2 Shown

[0022] The present invention provides a new type of electric chuck device based on a PLC control device, which includes a jaw 1, a chuck 2, a manual screw hole 3, a pressure sensitive sensor 4, a pressure plate 5, a chuck housing 6, a PLC control device 7, a linear Degree measuring device 8, transmission shaft 9, power pylon 10, bearing 11, electric motor 12, shaft sleeve 13, machine bed body 14 and wire 15, said jaw 1 is arranged on the left side of chuck 2; The manual knob 3 is arranged on the turning side of the chuck 2; the pressure-sensitive sensor 4 is arranged between the pressure plate 5 and the chuck housing 6; the PLC control device 7 is connected to the motor 12 through a wire 15; The straightness measuring device 8 is arranged between the transmission shaft 9 and the shaft sleeve 13; the power hanger 10 is arranged on the right side of the machine bed 14; the bearing 11 is arranged on the upper part of the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com