A kind of foamed thermoplastic polyurethane artificial leather and preparation method thereof

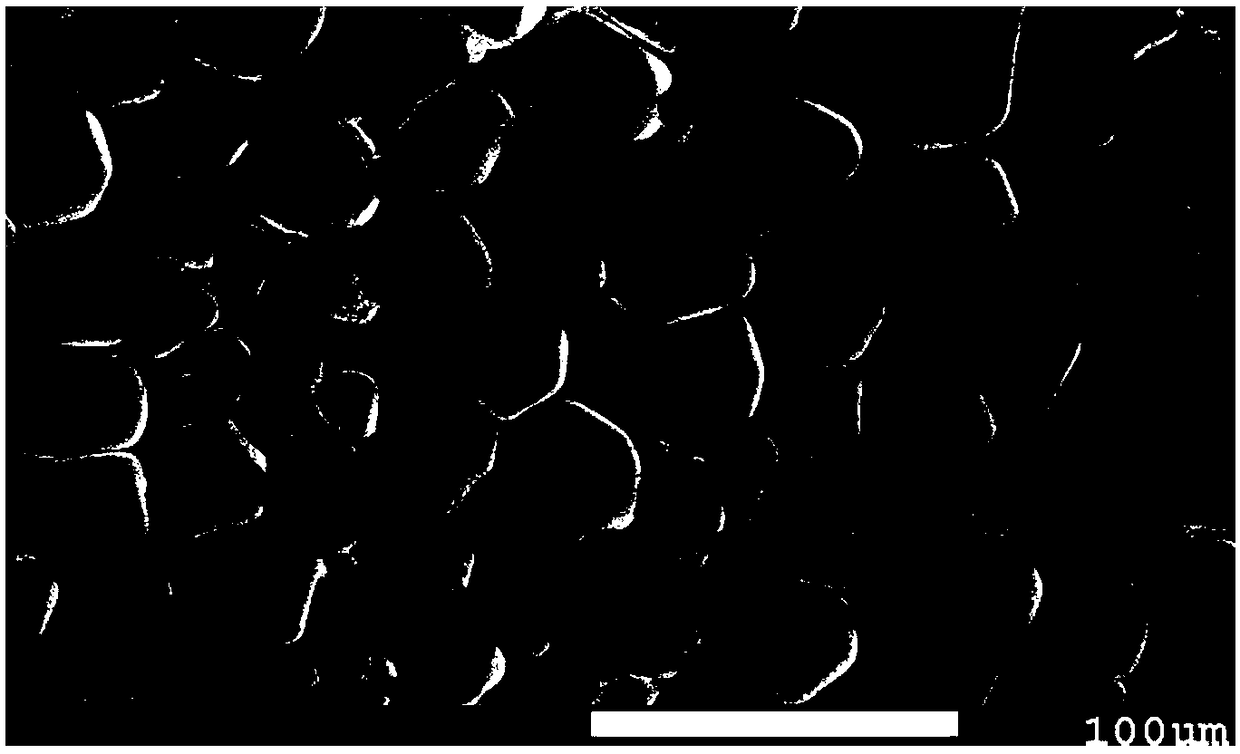

A technology of thermoplastic polyurethane and plastic polyurethane, which is applied in the field of artificial leather materials, can solve the problems of difficult control and stability of product quality, environmental protection, etc., and achieve the effect of good elasticity, high closed cell rate, and uniform cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 100 parts by weight of thermoplastic polyurethane particles A are dried at 100° C. for 4 hours and then put into an extruder. The extruder screw temperature is 120-150° C., and the surface layer is prepared by calendering;

[0031] Wherein, the thermoplastic polyurethane particle A has a Shore hardness of 50A and a melt flow rate of 20g / 10min, which is measured by applying a weight of 5kg at 200°C according to ASTM-1238;

[0032] (2) impregnating the fiber cloth with a water-based PU resin with a solid content of 10% for 10 minutes, and then drying it at 100° C. for 1 hour to obtain the bottom layer.

[0033] Wherein, the above-mentioned step (1) and step (2) procedures are in no particular order;

[0034] (3) Use a high mixer to mix 100 parts by weight of thermoplastic polyurethane particles B, 1 part by weight of PE wax, and 1 part by weight of color masterbatch into the first extruder, and control the screw temperature of the first extruder to be 150 -165-180-17...

Embodiment 2

[0038] (1) 100 parts by weight of thermoplastic polyurethane particles A are put into an extruder, the temperature of the screw of the extruder is 130-160° C., and the surface layer is prepared by casting process;

[0039] Wherein, the thermoplastic polyurethane particle A Shore hardness is 60A, and the melt flow rate is 30g / 10min, which is measured according to ASTM-1238 at 200°C by applying a weight of 5kg;

[0040](2) After impregnating the fiber cloth with a water-based PU resin with a solid content of 20% for 20 minutes, dry it at 100° C. for 2 hours to prepare the bottom layer.

[0041] Wherein, the above-mentioned step (1) and step (2) procedures are in no particular order;

[0042] (3) 100 parts by weight of thermoplastic polyurethane particles B, 2 parts by weight of erucamide, and 5 parts by weight of color masterbatch are uniformly mixed by a high-mixer and then added to the first extruder, and the temperature of the screw of the first extruder is controlled to be ...

Embodiment 3

[0045] (1) 100 parts by weight of thermoplastic polyurethane particles A are put into an extruder, the extruder screw temperature is 140-180° C., and the surface layer is prepared by calendering;

[0046] Wherein, the thermoplastic polyurethane particle A has a Shore hardness of 80A and a melt flow rate of 40g / 10min, which is measured by applying a weight of 5kg at 200°C according to ASTM-1238;

[0047] (2) After impregnating the fiber cloth with a water-based PU resin with a solid content of 40% for 30 minutes, dry it at 100° C. for 3 hours to prepare the bottom layer.

[0048] Wherein, the above-mentioned step (1) and step (2) procedures are in no particular order;

[0049] (3) 100 parts by weight of thermoplastic polyurethane particles B, 5 parts by weight of stearic acid amide, and 10 parts by weight of color masterbatch are mixed uniformly by a high-mixer and then added to the first extruder to control the temperature of the first extruder screw. 170-185-200-195°C to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com