Method for generating composite oxide nanotube array on high-entropy alloy surface

A technology of nanotube arrays and composite oxides, which is applied in the field of surface treatment of composite oxide nanotube films on the surface of high-entropy alloys, can solve the problems that oxide nanotubes have not been reported, and achieve simple equipment, simple operation, and maintenance The effect of completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

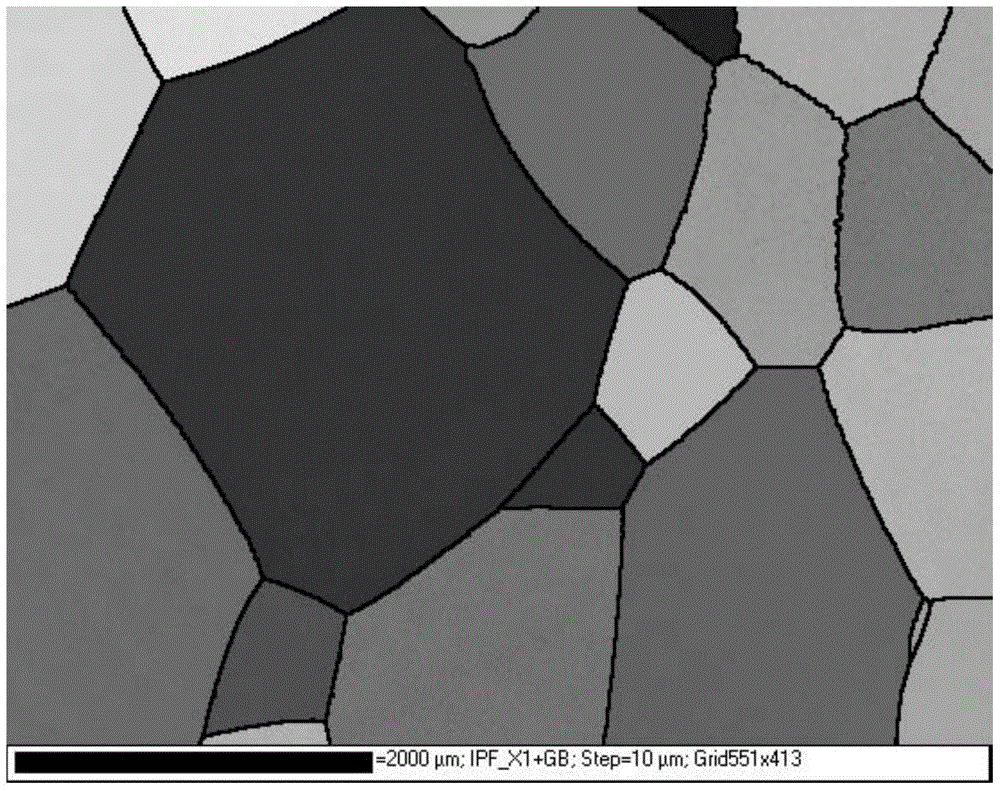

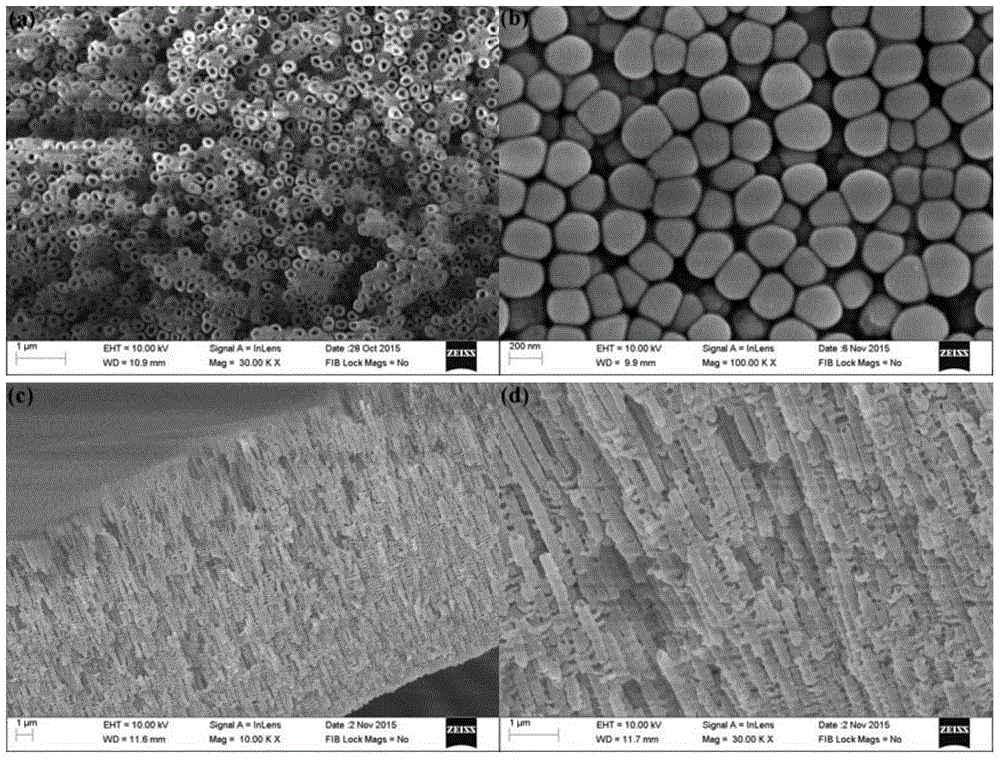

[0044] TaNbHfZrTi high-entropy alloy was melted by arc, and sucked into a 10×10mm water-cooled copper mold, the obtained high-entropy alloy rod was sucked, filled with argon gas to seal the tube, and then homogenized at 1400°C for 24h. figure 1 and figure 2 The XRD patterns and EBSD patterns of the prepared high-entropy alloys are respectively. It can be seen that the matrix alloy used is a typical BCC high-entropy alloy. Wire-cut to get 10×10×1mm slices, which are connected to copper wires and finally sealed together in a cold insert. The cold mount samples were carefully ground with 240#, 800#, 1000#, 2000# metallographic sandpaper in turn, ultrasonically cleaned with absolute ethanol, methanol, isopropanol and deionized water for 10 minutes each, and placed in N 2 Dry the surface of the sample in a stream of air.

[0045] Anodizing process: 1M (NH 4 ) 2 SO 4 +0.5wt%NH 4 F is the solute, water is used as the solvent, the oxidation voltage is 70V, the oxidation time i...

Embodiment 2

[0048] Using the same method, a typical FCC high-entropy alloy FeCoNiCrMn is selected, and the electrolyte is 0.35wt%NH 4 F + 3.0% deionized water in ethylene glycol solution, under the conditions of heating in a water bath at 60°C, the voltage is 40V, the oxidation time is 10h, and anodic oxidation is carried out. Similarly, regular composite oxide nanotube arrays with a length of about 10 μm can be obtained.

Embodiment 3

[0050] Using the same method, select the typical HCP high-entropy alloy ScYLaTiZrHf, and select the electrolyte as 1.0mol / L (NH 4 ) 2 SO 4 +0.1mol / LNH 4 F is the solute, water is used as the solvent, the voltage is selected as 80V, the oxidation time is 8h, and anodic oxidation is performed, and a regular array of composite oxide nanotubes with a length of about 20 μm can also be obtained.

[0051] The results of the examples show that choosing a suitable electrolyte, suitable oxide voltage, oxidation time and oxidation temperature, whether it is a high-entropy alloy with a BCC structure, a high-entropy alloy with an FCC structure, or a high-entropy alloy with an HCP structure Entropy alloys can generate composite oxide nanotube films on their surfaces. This is also the first time that high-entropy alloys have been used to prepare composite oxide nanotube arrays. Moreover, the prepared oxide nanotubes have exceptionally high thermal stability. Therefore, the nanotube oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com