Novel technology for preparing high-potassium-content and high-water-absorption resin by using carboxymethyl potato starch and acrylamide as raw materials

A technology of potato starch and superabsorbent resin, which is applied in the field of simple preparation, can solve the problems of little industrialization, and achieve the effects of reducing energy consumption, high water absorption, and high potassium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

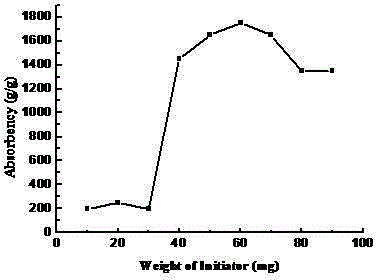

Embodiment 1

[0024] Example 1: Weigh 25g of acrylamide, dissolve it in 25ml of deionized water, weigh 9.86g of potassium hydroxide, dissolve it in 15ml of deionized water, add the potassium hydroxide solution dropwise to the above acrylamide solution, and stir at room temperature Hydrolyze acrylamide; weigh 2.5g carboxymethyl potato starch and mix with 30ml deionized water evenly, mix the hydrolyzate of acrylamide and carboxymethyl potato starch mixture evenly, add 4ml of potassium persulfate with a concentration of 10mg / ml Solution, 6ml of N,N'-methylenebisacrylamide solution with a concentration of 2.5mg / ml, nitrogen gas, slowly heating to gradually increase the temperature of the reaction system, the polymerization reaction occurs at 44°C, and when the temperature rises to 80°C Keep it warm for 1.5 hours, then take out the product, dry and pulverize to obtain a super absorbent resin. The water absorption of the super absorbent resin prepared in this example in 5000 times deionized water ...

Embodiment 2

[0025] Example 2: Weigh 25g of acrylamide, dissolve it in 25ml of deionized water, weigh 9.86g of potassium hydroxide, dissolve it in 15ml of deionized water, add the potassium hydroxide solution dropwise to the above-mentioned acrylamide solution, and stir at room temperature Hydrolyze acrylamide; weigh 2.5g carboxymethyl potato starch and mix with 30ml deionized water, mix the acrylamide hydrolyzate and carboxymethyl potato starch mixture evenly, add 6ml of potassium persulfate with a concentration of 10mg / ml Solution, 6ml of N,N'-methylenebisacrylamide solution with a concentration of 2.5mg / ml, nitrogen gas, slowly heating to increase the temperature of the reaction system gradually, the polymerization reaction occurs at 36°C, and when the temperature rises to 80°C Keep it warm for 1.5 hours, then take out the product, dry and pulverize to obtain a superabsorbent resin. The water absorption of the superabsorbent resin prepared in this example is 1750g / g in 5000 times deioniz...

Embodiment 3

[0026] Example 3: Weigh 25g of acrylamide, dissolve it in 25ml of deionized water, weigh 9.86g of potassium hydroxide, dissolve it in 15ml of deionized water, add the potassium hydroxide solution dropwise to the above acrylamide solution, and stir at room temperature Hydrolyze acrylamide; weigh 2.5g carboxymethyl potato starch and mix with 30ml deionized water, mix the acrylamide hydrolyzate and carboxymethyl potato starch mixture evenly, add 9ml of potassium persulfate with a concentration of 10mg / ml Solution, 6ml of N,N'-methylenebisacrylamide solution with a concentration of 2.5mg / ml, nitrogen gas, slowly heating to gradually increase the temperature of the reaction system, the polymerization reaction occurs at 39°C, and when the temperature rises to 80°C Keep it warm for 1.5 hours, then take out the product, dry and pulverize to obtain a super absorbent resin. The water absorption of the super absorbent resin prepared in this example in 5000 times deionized water is 1350 g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com