Container cell carrier for carrying at least one container cell and cleaning machine

A container room and cleaning machine technology, applied in the field of container room supports, can solve the problems of damaged cleaning, reduced bending stiffness, torsional stiffness and vibration stiffness, severe load of container room supports, etc., and achieves high stability and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] A preferred exemplary embodiment is explained below with reference to the drawings. Identical, similar or identically acting parts are identified with the same reference symbols. To avoid redundancy, part of the repeated description of the components is omitted below.

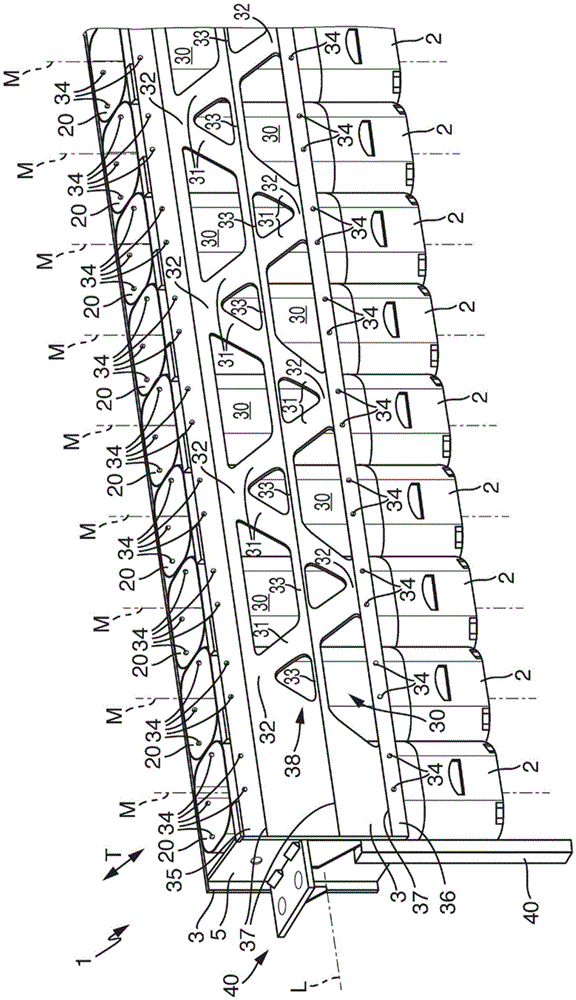

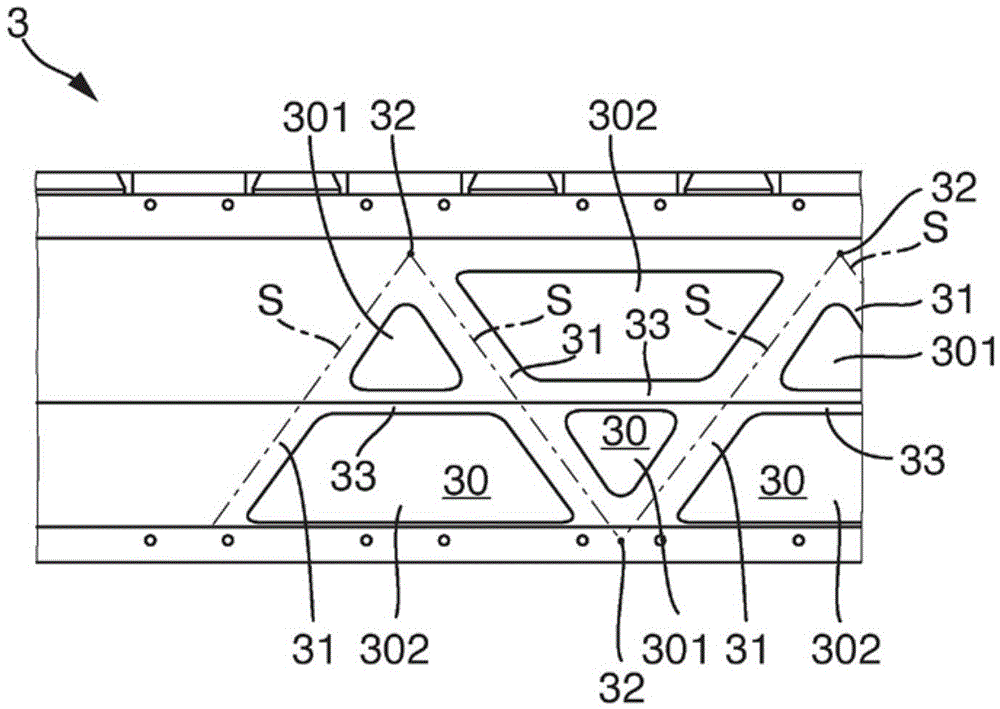

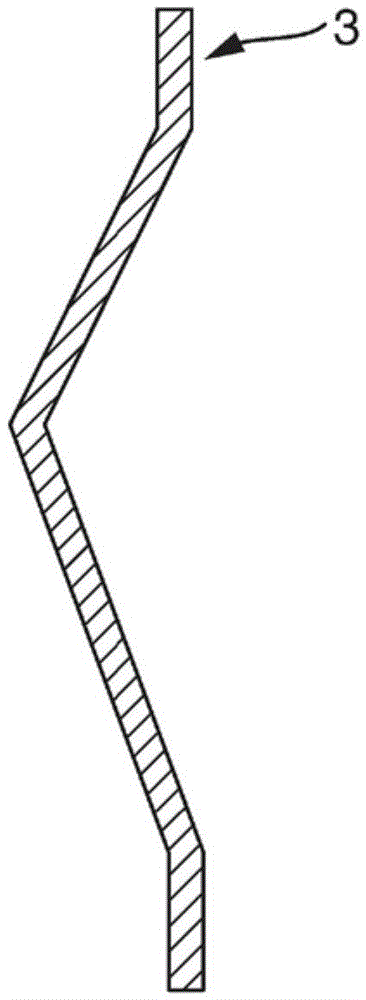

[0053] attached figure 1 The container chamber holder 1 with a plurality of container chambers 2 for holding containers to be cleaned in a washing machine is shown in a schematic perspective view. The container compartment frame has frame bars 3 on both sides that set the longitudinal axis L. Between the support bars 3 the container chamber 2 is arranged along the longitudinal axis L and is secured by the support bars 3 arranged on both sides. The container chambers 2 each have a container chamber center axis M perpendicular to the longitudinal axis L. As shown in FIG. The container chamber 2 has an inlet 20 on its upper side, through which containers to be cleaned can enter the container chamber 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com