High and large full-automatic waste lead-acid storage battery crushing and sorting system

A waste lead-acid battery and sorting system technology, which is applied in the direction of grain processing, etc., can solve the problems of long equipment production lines, easy blockage of crushers, unreasonable structure, etc., to reduce serious material leakage, improve recycling efficiency and environmental benefits, Achieving results at scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The preferred embodiment of the high and large-scale automatic waste lead-acid storage battery crushing and sorting system of the present invention is as follows:

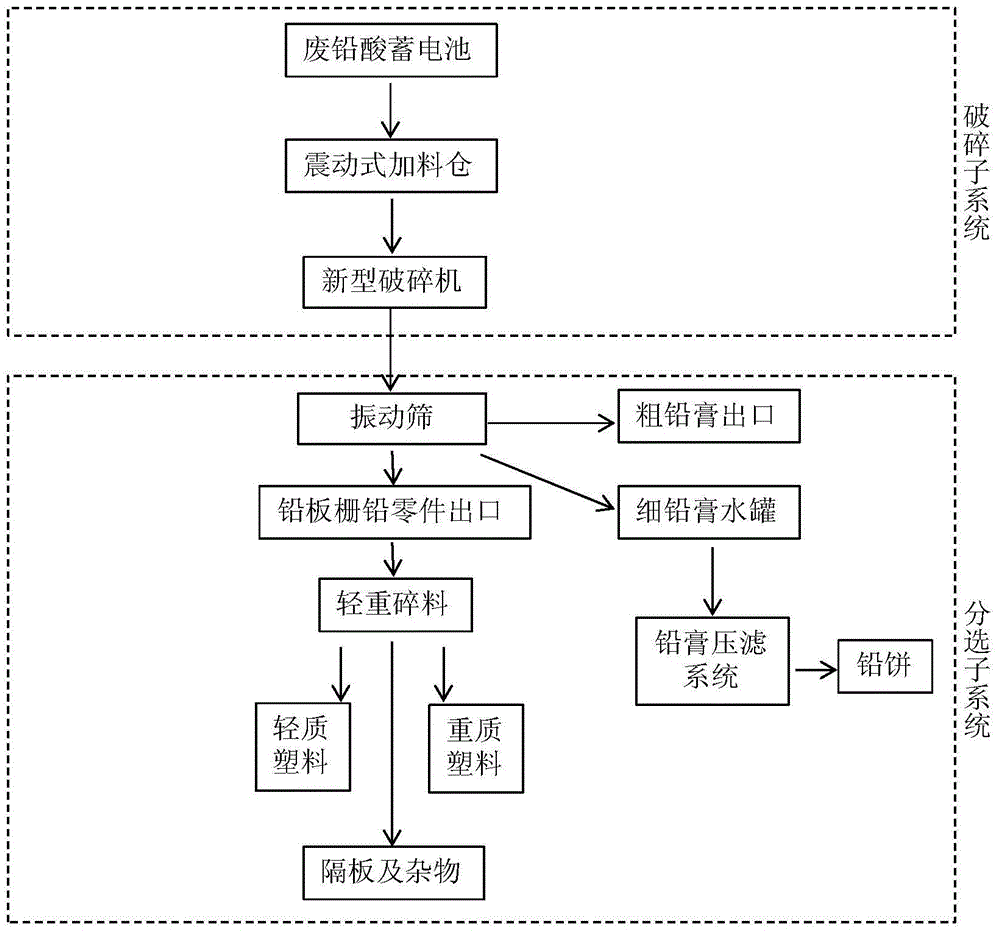

[0026] Including crushing subsystem and sorting subsystem;

[0027] The crushing subsystem includes a waste lead-acid battery storage bin, a vibrating feeding bin, and a hammer crusher connected in sequence;

[0028] The sorting subsystem includes a vibrating screen, the feed port of the vibrating screen is connected with the discharge port of the hammer crusher, and the vibrating screen is connected with a coarse lead plaster outlet, a fine lead plaster storage tank and a lead plate The outlet of the grid lead parts, the fine lead paste storage tank is connected with a fine lead paste filter press system, the outlet of the lead grid lead parts is connected to a multi-stage separator, and the multi-stage separator is provided with a heavy plastic outlet , Lightweight plastic outlets and partitions and sundr...

specific Embodiment

[0048] The high and large-scale automatic waste lead-acid battery crushing and sorting system of the present invention belongs to the waste lead-acid battery crushing and sorting treatment system in the secondary lead industry. The battery crushing subsystem and the crushing material sorting subsystem are mainly composed of crushing system, vibrating screen system, hydraulic separator, heavy plastic screw conveyor, acid mist scrubber, electrical control and monitoring system, etc.

[0049] Such as figure 1 As shown, in the crushing subsystem of the present invention, waste lead-acid batteries are transported to the crushing system through a vibrating feeding bin, and after being crushed by a heavy hammer high-speed impact crusher, they are transported to the primary and secondary vibrating screens, and the circulating water of the vibrating screens There is a lead mud receiving pool below the outlet, and there are fine lead paste water tanks and coarse lead paste outlets. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com