Method for measuring content of cerium in glass

A glass and content technology, applied in material excitation analysis, thermal excitation analysis, etc., can solve problems such as difficulty, complex composition of cover glass, dissolution, etc., and achieve the effect of small matrix effect, true and reliable detection results, and fast and accurate analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

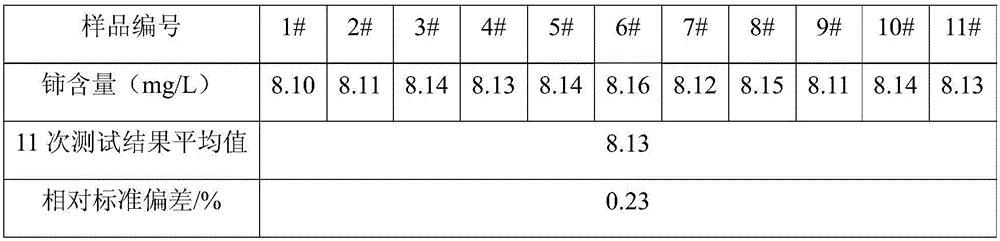

[0063] This example is used to illustrate the method for determining the content of cerium in glass according to the present invention.

[0064] (1) Use a glass knife to cut 35g from a flawless, flawless, cleaned and dried glass sample, put it into an agate mortar and grind it into a 3-8μm glass powder, put it in a ziplock bag and mix it evenly.

[0065] (2) Take out 10g of glass powder from the ziplock bag, put it into a washed and dried weighing dish, dry it in an oven at 110°C for 2 hours, put it in a desiccator and cool it to 25°C, and set it aside.

[0066] (3) Accurately weigh 0.1000g of dried glass powder with a precision electronic balance, and place it in a cleaned and dried platinum crucible, then add 9ml of high-grade pure hydrofluoric acid into the platinum crucible, and place the platinum crucible in Heat at 250°C for 25 minutes on a resistance furnace to completely consume high-grade pure hydrofluoric acid, then add 2.5ml of high-grade pure perchloric acid to the...

Embodiment 2

[0092]According to the method of Example 1, the difference is that in step (3), the method for obtaining the complete solution of glass powder is: accurately weigh 0.1000g of dried glass powder with a precision electronic balance, and place it in a cleaned and dried In a dry platinum crucible, add 9.5ml of superior grade pure hydrofluoric acid into the platinum crucible, place the platinum crucible on a resistance furnace and heat it at 220°C for 40min to completely exhaust the superior grade pure hydrofluoric acid, and then add it to the platinum Add 3ml of high-grade pure perchloric acid into the crucible, and heat it on a resistance furnace at 320°C for 60 minutes to completely dissolve the glass powder to obtain a complete solution of the glass powder.

[0093] After measurement, the cerium content of the constant volume solution is 8.13mg / L, and after calculation, the cerium content in the glass sample is 0.4065wt%.

Embodiment 3

[0095] According to the method of Example 1, the difference is that in step (3), the method for obtaining the complete solution of glass powder is: accurately weigh 0.1000g of dried glass powder with a precision electronic balance, and place it in a cleaned and dried dry platinum crucible, then add 10ml of high-grade pure hydrofluoric acid into the platinum crucible, place the platinum crucible on a resistance furnace and heat it at 260°C for 20min to completely exhaust the high-grade pure hydrofluoric acid, and then pour into the platinum crucible Add 3.5ml of high-grade pure perchloric acid to the solution, and heat it on a resistance furnace at 360°C for 40 minutes to completely dissolve the glass powder to obtain a complete solution of the glass powder.

[0096] After measurement, the cerium content of the constant volume solution is 8.14mg / L, and after calculation, the cerium content in the glass sample is 0.407wt%.

[0097] The method for measuring the cerium content in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com