Method for simulating corrosion of weathering resistant steel in high-moist-heat marine atmosphere

A marine atmosphere and weather-resistant steel technology, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of unreported test methods and achieve good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

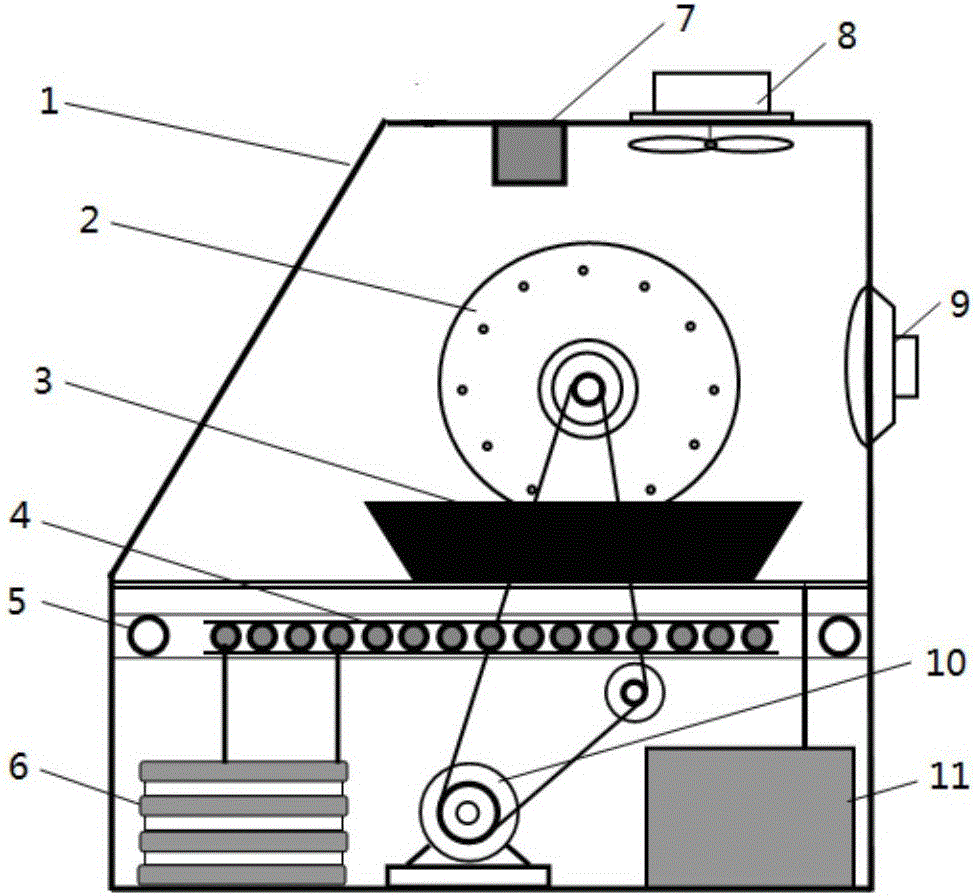

Method used

Image

Examples

Embodiment 1

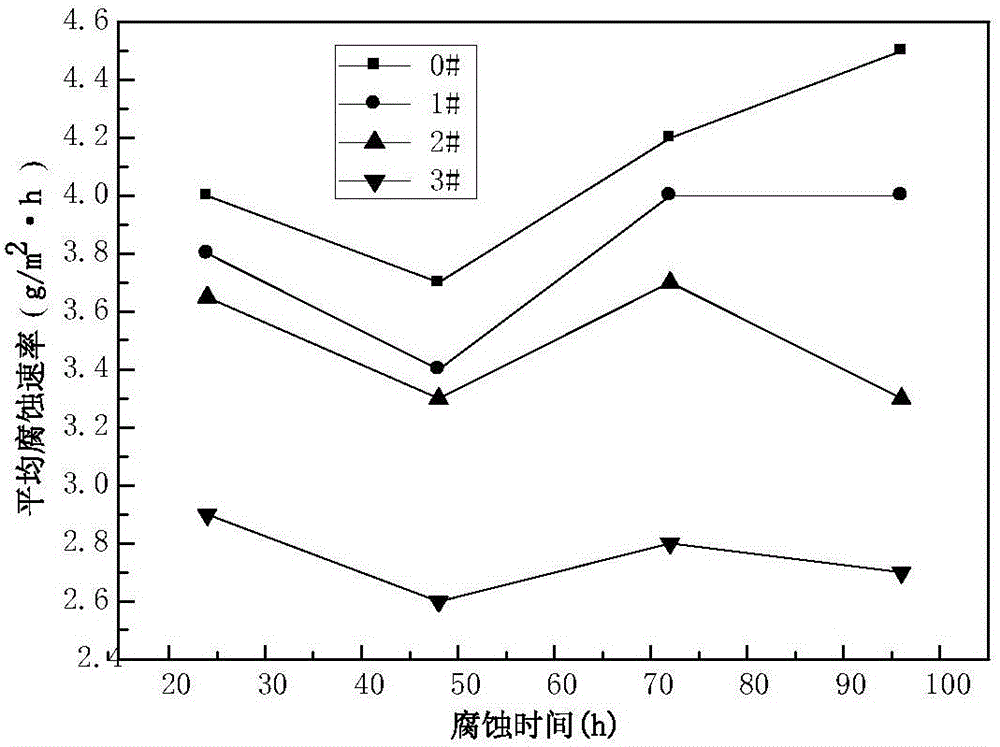

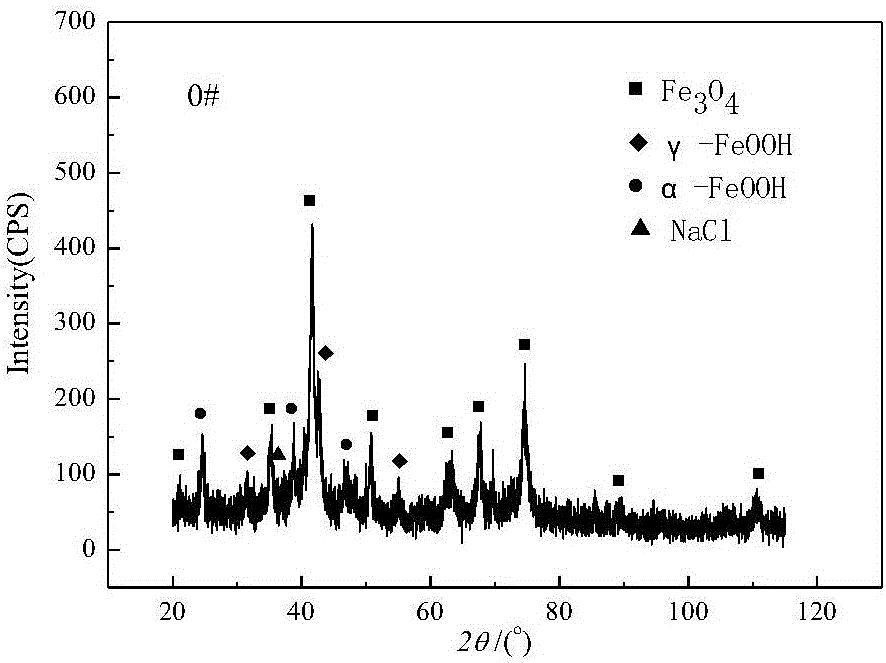

[0046] Adopt four kinds of weathering steel grades, carry out the method for simulating high-humidity marine atmospheric corrosion of the present invention, wherein 0# is contrast steel, is the common weathering steel that domestic certain steel factory produces, and 1#, 2# and 3# are experimental The material composition of the weathering steel smelted in the laboratory is shown in Table 1.

[0047] Table 14 Chemical composition of experimental weathering steel

[0048] steel C S P mn Si Cr Ni Cu Nb 0#(Q450NR1) 0.075 0.0068 0.012 0.80 0.39 0.50 0.19 0.24 0.035 1# 0.070 0.0045 0.0050 0.88 0.40 0.54 0.95 0.27 0.0046 2# 0.069 0.0058 0.0058 0.87 0.36 0.51 1.90 0.27 0.0033 3# 0.081 0.0058 0.0062 0.90 0.40 0.51 2.93 0.27 0.0038

[0049] Cut the sample weathering steel into small samples with a size of 60mm (length) × 40mm (width) × (3mm~5mm) (thickness), then deburr, clean and dry with hot air, and use...

Embodiment 2

[0053] Cut the four kinds of weathering steel test materials into small samples with the size of 150mm (length) × 75mm (width) × (3mm~5mm) (thickness), and then carry out deburring, cleaning and hot air drying, and use them first when cleaning. Gasoline or petroleum ether, then absolute ethanol, and finally acetone, then measure and record the original size (accurate to 0.1mm) and mass (accurate to 1mg) of the sample, and carry out the atmospheric exposure test. The exposure test standard refers to ISO-4524 It was carried out in a certain area of the South China Sea. The test period is 2014.4-2015.4. The size of the exposure sample is 150mm (length) × 75mm (width) × (3mm ~ 5mm) (thickness), and the exposure period is 1 year. After the exposure test, the samples were processed, and the corrosion weight loss and phase analysis of the rust layer were carried out.

[0054] Figure 7 It is the histogram of the average corrosion rate of four kinds of samples in the field of emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com