A kind of ultra-low temperature refrigeration method

An ultra-low temperature refrigeration and refrigerant technology, which is used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of fluctuation in refrigeration capacity, small fan pressure, and excessive adjustment flow, and achieve continuous and stable maintenance and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

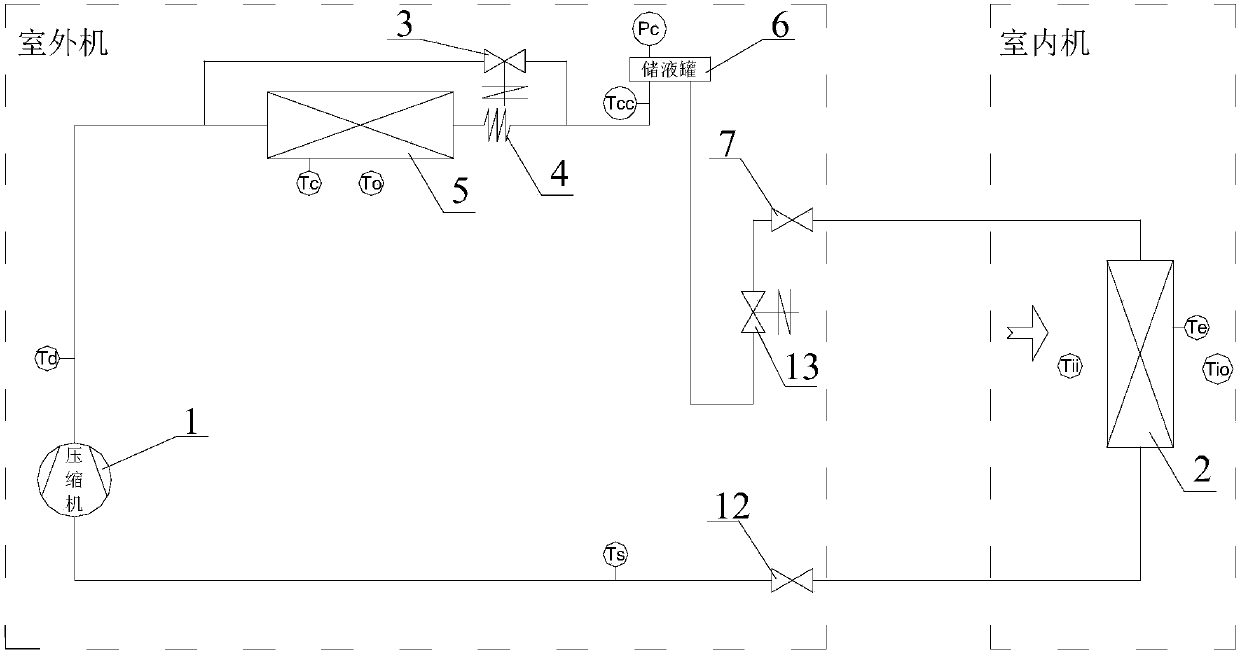

[0027] see figure 1 , the single-cooling split air conditioner of the present invention can refrigerate at ultra-low temperature, including a compressor 1, a condenser 5, an evaporator 2, an electronic expansion valve-3 for bypass, a capillary tube 4 for partial pressure, a liquid storage tank 6, and at least one throttle element, at least one auxiliary device, at least one shut-off valve. The compressor 1, the condenser 5, and the evaporator 2 form a refrigerant cycle.

[0028] Throttle elements, auxiliary devices, and stop valves can be set according to actual conditions. Valves may include liquid valves, gas valves, and the like. In this embodiment, the throttling element includes electronic expansion valve II 13, the auxiliary devices include pressure sensor Pc, thermometer Tcc, Tc, To, Td, Ts, Tii, Te, Tio, etc., and the stop valve includes liquid valve 7, gas valve 12.

[0029] The compressor 1 and the condenser 5 constitute the main frame of the outdoor unit, and th...

Embodiment 2

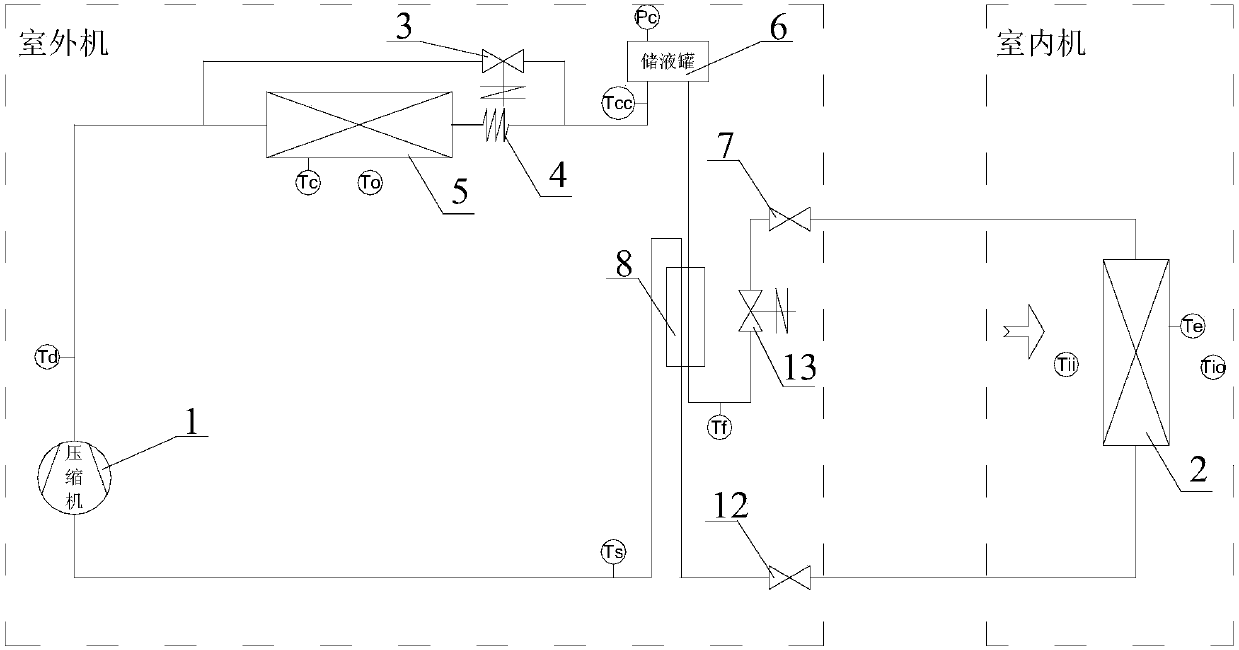

[0037] see figure 2 , the cooling-only split-type air conditioner in Embodiment 2 is basically the same as the cooling-only split-type air conditioner in Embodiment 1, the difference being that the cooling-only split-type air conditioner in Embodiment 2 also includes a heat regenerator 8 . After coming out of the liquid storage tank 6, the liquid refrigerant passes through the regenerator 8 and then is connected to the evaporator 2, and then passes through the regenerator 8 to the compressor 1 after coming out of the evaporator 2.

[0038] That is to say, the regenerator 8 (between the liquid storage tank 6 and the throttling element) is added on the basis of the first application example. The liquid refrigerant at the outlet of the liquid storage tank 6 is close to saturation. In order to ensure a more stable operation of the system, the near-saturated liquid refrigerant at the outlet of the liquid storage tank 6 exchanges heat with the refrigerant on the suction side of the...

Embodiment 3

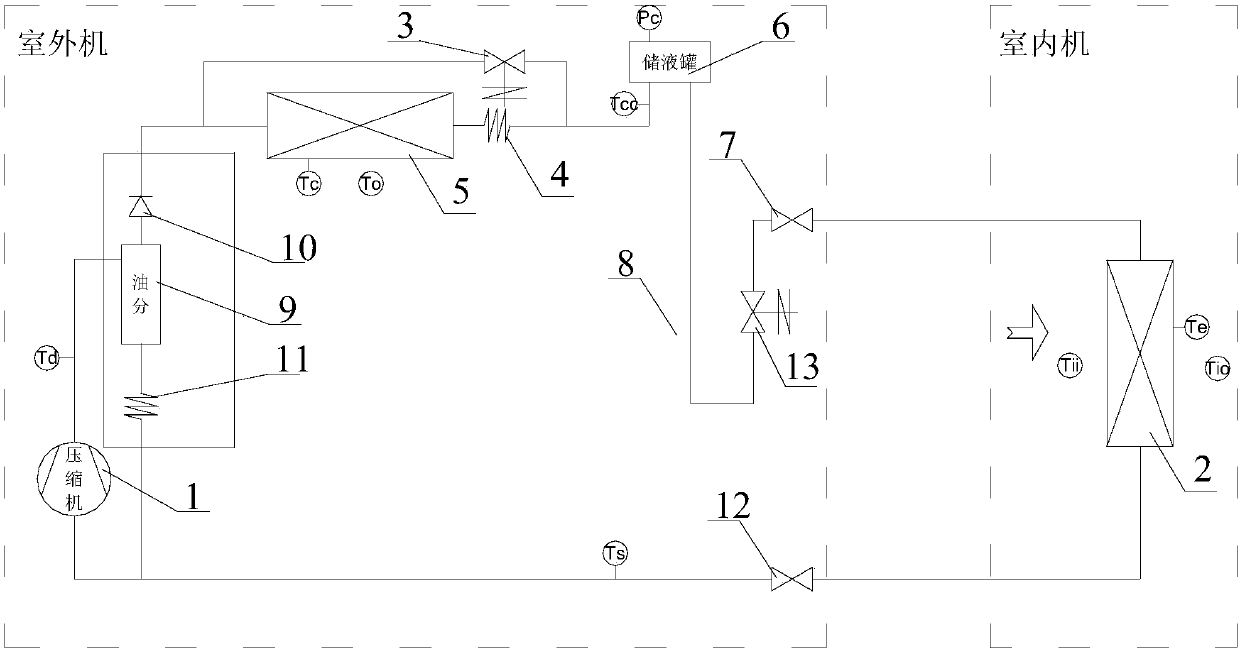

[0040] see image 3, the cooling-only split-type air conditioner in Embodiment 3 is basically the same as the cooling-only split-type air conditioner in Embodiment 1, and the difference is that the cooling-only split-type air conditioner in Embodiment 3 also includes an oil separator 9 and a check valve 10 11. Oil separation capillary. The gaseous refrigerant is compressed by the compressor 1 and enters the oil separator 9 to be separated into the gaseous refrigerant accompanied by lubricating oil and the gaseous refrigerant from which the lubricating oil has been separated, and the gaseous refrigerant accompanied by lubricating oil returns to the compressor 1 through the oil separation capillary 11 The suction port re-enters the compressor 1; the gaseous refrigerant from which the lubricating oil has been separated is discharged from the oil separator 9 and enters the condenser 5 through the check valve 10.

[0041] On the basis of Application Example 1, add oil separator 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com