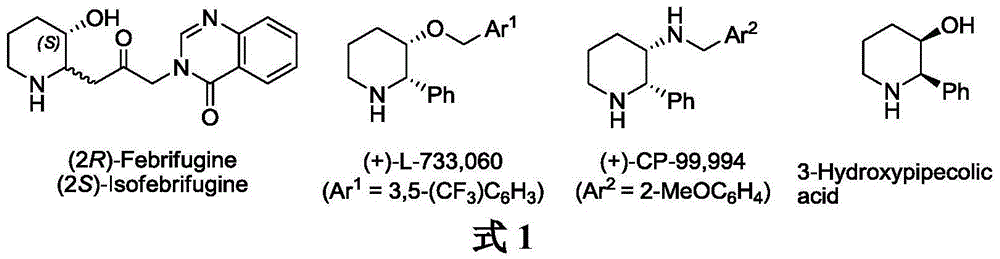

Method for synthesis of 3-piperidone derivatives through iridium catalytic hydrogenation

A technology of piperidone and hydrogen catalysis, which is applied in the field of synthesizing 3-piperidone derivatives, can solve the problems of cumbersome steps, difficult to scale up synthesis, and long routes, and achieve simple reaction operations, short synthetic routes, and high atom economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

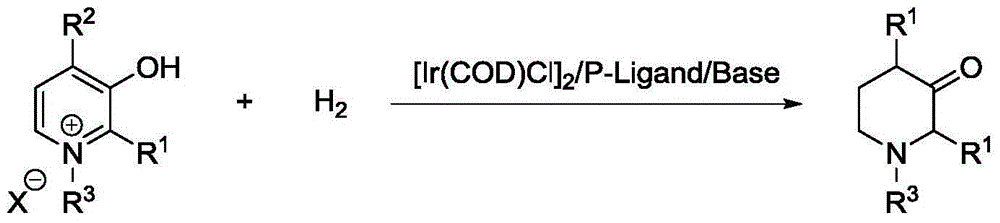

Method used

Image

Examples

Embodiment 1

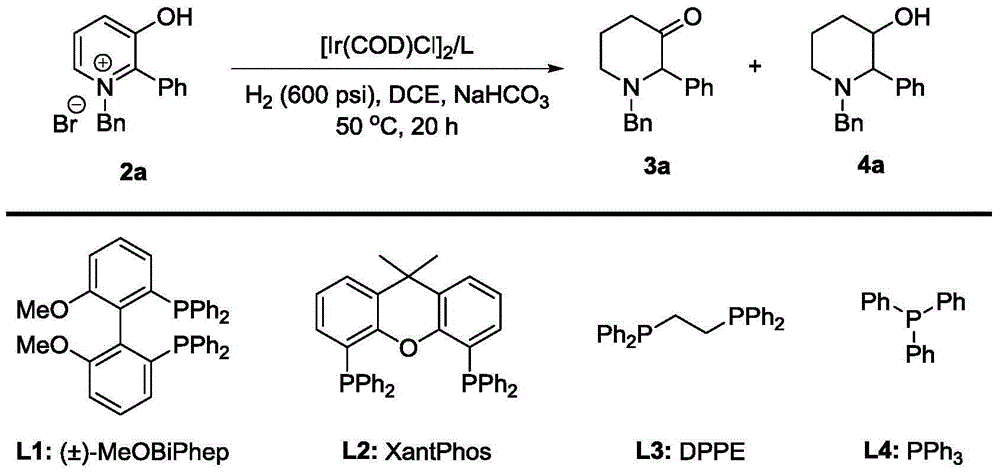

[0031] Embodiment 1: optimization of conditions

[0032] In a nitrogen-filled glove box, the (1,5-cyclooctadiene) iridium chloride dimer (0.001 mmol, 0.7 mg) and the phosphine ligand (0.0022 mmol or 0.0044 mmol) Add 1 milliliter of 1,2-dichloroethane solvent in the reaction bottle, stir at room temperature for 10-15 minutes, then transfer the prepared catalyst to another container containing raw material 3-hydroxypyridinium salt 2a (0.20 mmol, 68.5 mg) and sodium bicarbonate (0.2 mmol, 16.8 mg), wash the bottle with 2 ml of solvent, transfer the residual catalyst, and share 3 ml of solvent 1,2-dichloroethane. The reaction bottle was put into a stainless steel autoclave, hydrogen gas was introduced at 600 psi, and the reaction was carried out at 50° C. for 20 hours. Slowly release hydrogen, filter the reaction solution, remove the solvent with a rotary evaporator and then directly column chromatography (the volume ratio of the eluent petroleum ether and ethyl acetate is 5:1), ...

Embodiment 2

[0037] Embodiment 2: Synthesis of 3-piperidone derivatives by homogeneous iridium catalyzed hydrogenation

[0038] In a nitrogen-filled glove box, (1,5-cyclooctadiene) iridium chloride dimer (0.001 mmol, 0.7 mg) and triphenylphosphine ligand (0.0044 mmol, 1.2 mg ) into the reaction flask of 1 milliliter of solvent 1,2-dichloroethane, stirred at room temperature for 10-15 minutes, then transferred the prepared catalyst to another containing raw material 3-hydroxypyridinium salt 2 (0.20 mmol ) and sodium bicarbonate (0.2 mmol, 16.8 mg), wash the bottle with 2 ml of solvent, transfer the residual catalyst, and share 3 ml of solvent 1,2-dichloroethane. Put the reaction bottle into a stainless steel autoclave, feed hydrogen gas at 600psi, and react at 50°C for 20-30 hours. Slowly release hydrogen, filter the reaction solution, remove the solvent with a rotary evaporator, and then direct column chromatography (the volume ratio of eluent petroleum ether and ethyl acetate is 10:1-3:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com