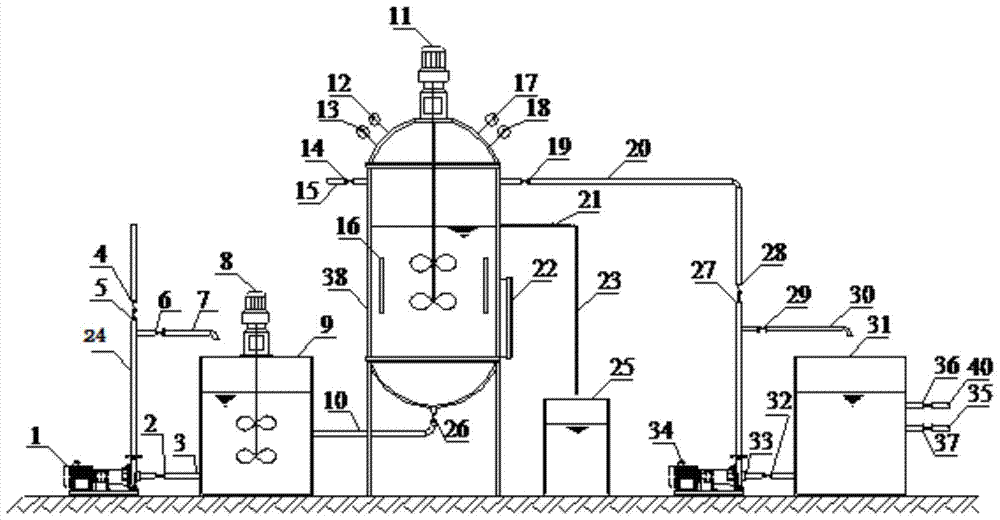

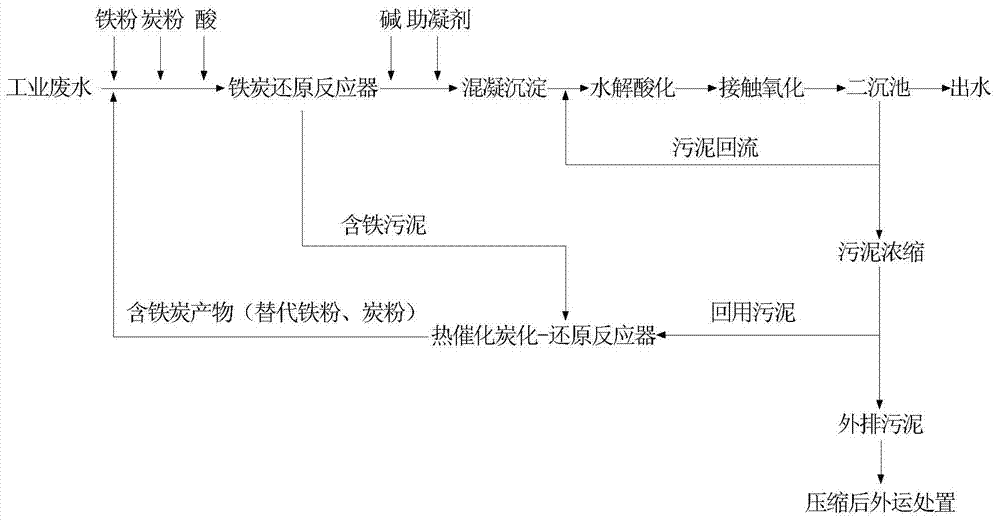

An iron-carbon reduction-biological combined treatment method and device for iron circulation and sludge reduction

A sludge reduction and treatment device technology, which is applied in the direction of electrochemical biological combination treatment, sludge treatment, biological water/sewage treatment, etc., can solve the problems of high cost of acid and alkali addition, high iron sludge production and high disposal cost , to achieve the effect of saving sludge disposal fees, saving wastewater treatment costs, and saving project operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A printing and dyeing enterprise discharges wastewater including printing, dyeing, scouring, and desizing wastewater. The mixed wastewater COD=3000-4000mg / L, after treatment, it needs to meet the discharge standard of COD≤200mg / L and discharge it into the sewage pipe of the industrial park network. The iron-carbon reduction-biological combination treatment process of iron circulation and sludge reduction proposed in this embodiment is adopted. The specific methods and steps are: (1) the biochemical effluent of printing and dyeing wastewater enters iron-carbon reduction-hydrolytic acidification-aerobic treatment, and the treatment The final effluent COD≤200mg / L; (2) Feed the iron-containing sludge produced by the iron-carbon reduction unit and the residual sludge from biological treatment into the thermal catalytic carbonization-reduction reactor at a ratio of 3:1; (3) Seal The thermal catalytic carbonization-reduction reactor reacts at 185°C for 7.0 hours to carbonize t...

Embodiment 2

[0039] In an environmental protection service center, the COD of wastewater collected from offshore oil production platforms is 25000-30000mg / L. There are many organic suspended solids in the wastewater, which are difficult to remove by traditional flocculation and sedimentation, thus reducing the scaling and effectiveness of subsequent evaporation devices. The wastewater is treated with iron-carbon reduction-anaerobic-aerobic process, and the water quality is relatively clear, which can meet the water intake of the subsequent evaporation device; however, a large amount of iron-containing sludge and residual sludge are produced during the iron-carbon reduction and biological treatment process, which is difficult to dispose of and higher costs. The iron-carbon reduction-biological treatment combined process of iron circulation and sludge reduction proposed in this embodiment is used for treatment. The specific methods and steps are: (1) the wastewater from the oil production pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com