Method for treating wastewater with conductive filter material and achieving regeneration

A technology for filtering materials and treating waste water, applied in the environmental field, can solve the problems of increasing the cost of backwashing, secondary pollution, incomplete backwashing, and speeding up the washing speed, and achieves easy automatic control, high elution efficiency, and short processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

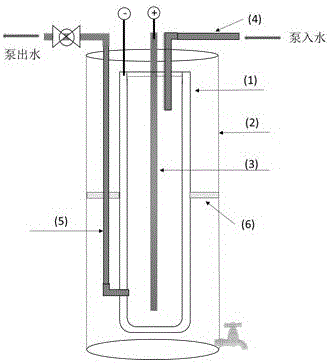

[0022] Conductive tungsten carbide filter material is used for the filtration treatment of turbid surface water. like figure 1 As shown, the experimental device includes a filter tube 1 with a length of 30 cm, an inner diameter of 4 cm, and a thickness of 2 cm. The filter tube is a porous ceramic filter tube made of tungsten carbide (the average pore size is 0.1-1 micron), and the ceramic tube is connected to the cathode of the DC power supply through a metal molybdenum wire. There is also a ruthenium-titanium thin rod anode in the middle of the filter tube, with a length of 30 cm, which is used as the anode of the electrolysis process during work, and the connection mode of the lead is the same as that of the cathode. Water inlet pipe 4 and water outlet pipe are arranged on the filter pipe, and the remaining parts are sealed, and the pumping pressure is 0.2-0.4MPa during work. The filter tube is placed in the clean water tank 2. During operation, the clean water passing thr...

Embodiment 2

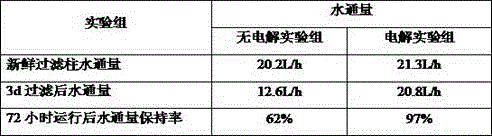

[0028] Electroactive tungsten carbide filter material is used for the treatment of oily catering wastewater. The experimental device, material manufacturing method and experimental method of Example 2 are the same as those of Example 1, and the obtained experimental results are shown in the table below. The oily catering wastewater was taken from the grease trap of a catering wastewater treatment facility, and the oil content was determined to be 0.45g / L after organic solvent extraction, and the filtration experiment run period was 72 hours. Record the water level in the clean water tank and calculate the water output in a certain unit time. The result is as follows:

[0029]

[0030] It can be seen that the water flux retention rate of the electrolysis experimental group after 72 hours is significantly higher than that of the non-electrolysis group, indicating that electrolysis can maintain the treatment capacity for oily catering wastewater and maintain the water flux re...

Embodiment 3

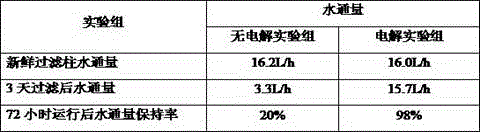

[0032] Titanium nitride filter material is used for the filtration treatment of turbid surface water. The experimental device is the same as in Example 1, but the material of the filter tube used is titanium nitride filter material, and the electrical connection is the surface contacting the titanium nitride layer. The filter material is based on an ordinary alumina tube, depositing a layer of porous titanium nitride electroactive covering layer (inner wall of the tube), the layer thickness is 0.7mm, and the average pore size of the active layer is 0.7 microns. Experimental group 1 did not apply electric field, and experimental group 2 applied electric field, and carried out electrolysis while filtering. After the filtration starts, the pumping pressure is controlled to be 0.2MPa, the operation period is 3 days, the voltage of the electrolysis group is 5V, and the water quality parameters of the treated surface water are the same as those in Example 1.

[0033] Record the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com