Dissolution system and method for gibbsite-type bauxite in parallel tubes plus retention tank

A gibbsite-type and bauxite technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of no mixing facilities, difficulty in large-scale single-series production capacity, affecting heat transfer efficiency, etc., to improve the pulp processing capacity , It is conducive to uniform mixing and the effect of reducing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

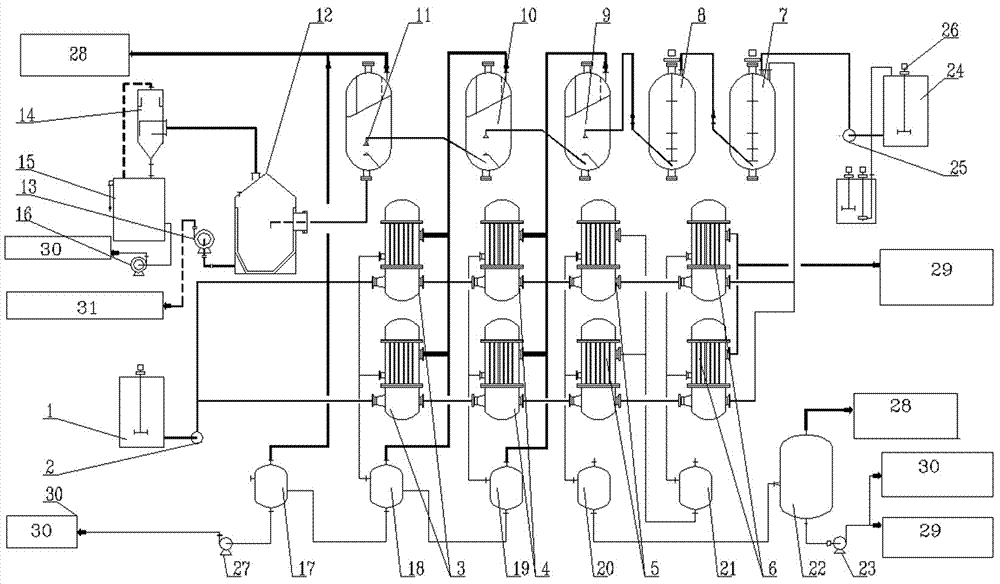

[0043] The structure of the dissolution system of gibbsite-type bauxite with parallel tubes and retention tanks is as follows: figure 1 As shown, it includes a circulating mother liquor tank 1, a double-series parallel tube heating device, a mixer 7, a heat preservation tank 8, a flash device and a dilution device; the circulating mother liquor tank 1 is heated by a mother liquor feeding pump 2 and a double series of parallel tubes The device is connected, and the double-series parallel tube heating device is composed of 2 sets of tube heating devices connected in parallel. Each group of tube heating devices is composed of a first-level tube preheater 3, a second-level tube preheater 4, and condensate water tube heating. The device 5 and the new steam tube heater 6 are sequentially connected in series, and each tube preheater and tube heater are equipped with a medium inlet, a medium outlet, a material inlet and a material outlet; the circulating mother liquor tank 1 is fed thr...

Embodiment 2

[0063] The structure of the stripping system of the gibbsite type bauxite in parallel and the retention tank is the same as in embodiment 1;

[0064] The gibbsite-type bauxite stripping method of parallel tubes plus retention tanks of the present embodiment adopts the above-mentioned stripping system, and proceeds according to the following process steps:

[0065] (1) The circulating mother liquor in the circulating mother liquor tank is transported to the double-series parallel tube heating system through the mother liquor feeding pump. The mother liquor first enters the first-stage tube preheater of each group of tube heating devices, The medium inlet of the tube preheater is passed into the secondary steam to heat the circulating mother liquor, and the circulating mother liquor enters the second-stage tube preheater after being heated, and the secondary steam heating cycle is passed into the medium inlet of the second-stage tube preheater The mother liquor and the circulati...

Embodiment 3

[0078] The structure of the dissolution system of gibbsite-type bauxite in parallel tubes plus residence tanks is the same as that in Example 1, the difference being that the double-series parallel tube heating devices are composed of three sets of tube heating devices connected in parallel;

[0079] The gibbsite-type bauxite stripping method of parallel tubes plus retention tanks of the present embodiment adopts the above-mentioned stripping system, and proceeds according to the following process steps:

[0080] (1) The circulating mother liquor in the circulating mother liquor tank is transported to the double-series parallel tube heating system through the mother liquor feeding pump. The mother liquor first enters the first-stage tube preheater of each group of tube heating devices, The medium inlet of the tube preheater is passed into the secondary steam to heat the circulating mother liquor, and the circulating mother liquor enters the second-stage tube preheater after bei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com