Supercritical carbon dioxide circulating fluidized bed coal fired boiler and power generation system driven by same

A circulating fluidized bed and carbon dioxide technology, which is applied in fluidized bed boilers, steam boilers, steam generation, etc., can solve the problems of relatively large steam temperature efficiency improvement, achieve size reduction, promote uniform distribution, and high cycle efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

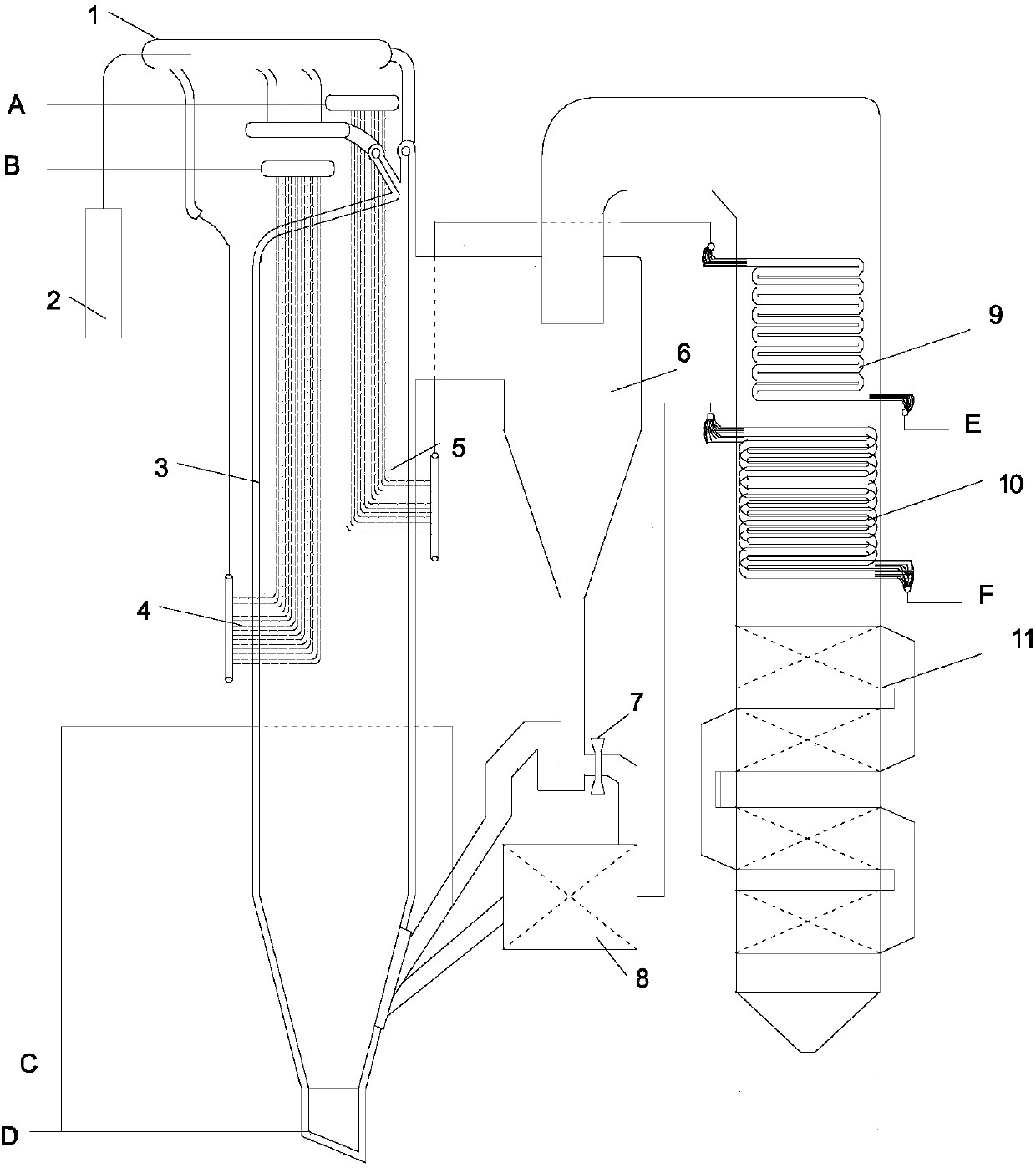

[0025] Referring to Figure 1(a), the supercritical carbon dioxide circulating fluidized bed coal-fired boiler includes a supercritical carbon dioxide gas box 1, a gas storage station 2, a film-type supercritical carbon dioxide cold wall in the furnace 3, a panel heater 4, and a screen High-temperature reheater 5, high-temperature adiabatic cyclone separator 6, ash control valve 7, external upper-level economizer 8, low-temperature reheater 9, lower-level economizer 10 and the lower-level economizer arranged in sequence along the flue gas flow direction in the tail flue Air preheater 11. The gas storage station 2, the supercritical carbon dioxide cold wall 3, and the furnace panel heater 4 are all connected to the supercritical carbon dioxide gas tank 1. Among them, the gas storage station 2 and the supercritical carbon dioxide gas tank 1 are two-way connected, and the flow direction of the working fluid between the gas storage station 2 and the supercritical carbon dioxide gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com