Heat conductive graphite film preparation method and graphite crucible

A heat-conducting graphite film and graphite crucible technology, which is applied in the field of graphite crucibles, can solve the problems of unqualified heat-conducting physical and mechanical properties of large-scale graphite films, and achieve the effects of increasing single-time production, reducing production costs, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

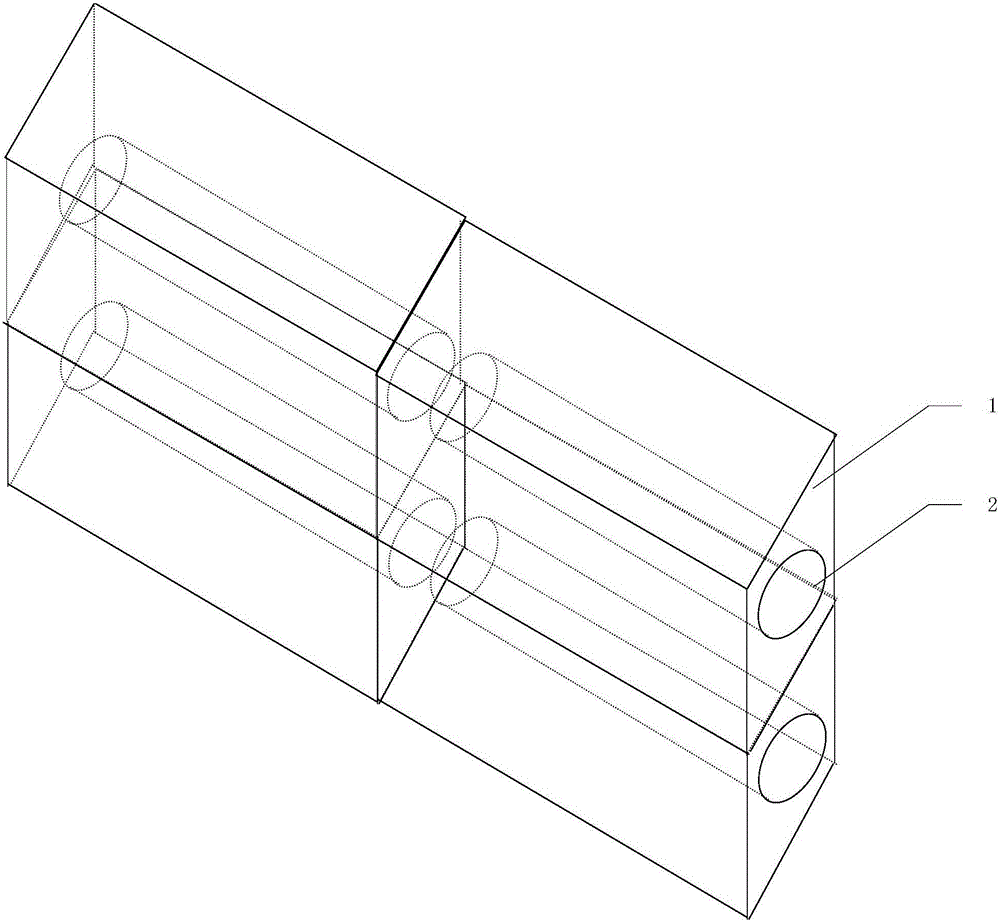

[0039] Please refer to figure 1 , the graphite crucible is a cubic graphite crucible 1, and the cubic graphite crucible 1 is provided with a cylindrical cavity 2, the original material film is placed in the cylindrical cavity 2, and the graphite crucible is stacked on In the carbonization furnace and graphitization furnace, the original film is carbonized and graphitized.

[0040] Further elaborate the preparation method of thermally conductive graphite film of the present invention:

Embodiment 2

[0042] Select a polyimide (PI) film coil material with a thickness of 70 μm and a width of 700 mm to prepare a mixed aqueous solution of ferric chloride and ferric nitrate with a mass concentration of 5%, wherein the content of ferric chloride is 4%, and the content of ferric nitrate It is 1%, and the aqueous solution contains 2% sodium lauryl sulfate. Unfold the PI film coil and pass it through the spraying device, spray a layer of the above mixed solution evenly on the surface, after spraying, evaporate the water through a dryer to obtain the original film, and compound a layer of 2mm thick on the original film. Graphite paper, then raw material film and graphite paper are wound and rolled, and the width of coiled material is suitable with raw material film coiled material size, and radius size is 95mm, selects and is long the graphite crucible described in embodiment 1 of 800mm, rolls The graphite crucible is loaded into a cylindrical cavity with a radius of 100mm, and the ...

Embodiment 3

[0048] Select the polyimide (PI) film roll material that thickness is 70 μm, and width is 720mm, the preparation mass concentration is the mixed ethanol solution of ferric chloride, cobalt chloride, ferric nitrate, cobalt nitrate, wherein ferric chloride The content is 3%, the content of cobalt chloride is 2%, the content of ferric nitrate is 3%, the content of cobalt nitrate is 2%, and the ethanol solution contains 1% of surfactant sodium lauryl sulfate. Spread the PI film through the spraying device, spray a layer of the above-mentioned mixed solution on the surface evenly, after spraying, evaporate the water through a dryer to obtain the original film, and compound a layer of graphite paper with a thickness of 2mm on the original film , and then wind the original film and graphite paper into a roll. The width of the coil is equivalent to the size of the original film coil, and the radius is 70mm. The graphite crucible of embodiment 1 with a length of 800mm is selected, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com