Preparation method of blocky porous carbon with large specific surface area

A technology with high specific area and high specific surface area, which is applied in the field of porous carbon, can solve problems such as difficulty in ensuring product consistency, difficult control of pressure and temperature, unfavorable industrial production, etc., achieving less production equipment, convenient operation, and suitable for large-scale The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

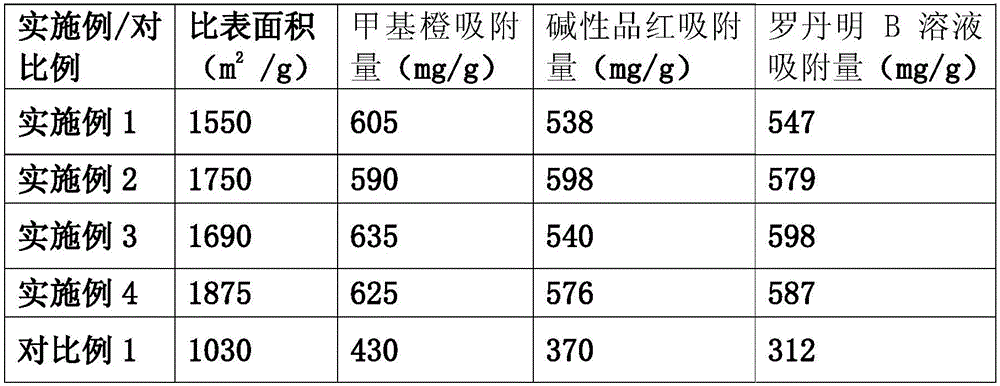

Examples

Embodiment 1

[0015] A preparation method of high specific area block porous carbon, mixing according to the mass ratio of phenols: sugars: water: ionic liquid = 1: 1: 10: 0.01, firstly, mixing phenols and sugars, and then adding Deionized water is used to fully dissolve the phenols and sugars in the mixture at 50°C, then add the ionic liquid, stir and mix evenly at 50°C, place in a microwave oven with a power of 1000w, and heat for 10s to obtain The material is washed with water and ethanol and then dried to obtain a bulky porous carbon material with a high specific surface area.

[0016] The phenols are phenol; the sugars are glucose; the ionic liquid is N-methylbutylpyrrolidine bis-trifluoromethanesulfonimide salt

Embodiment 2

[0018] A preparation method of a high specific area block porous carbon, mixing according to the mass ratio of phenols: sugars: water: ionic liquid = 1:4:40:1, first mixing the phenols and sugars, and then adding Deionized water, and stirred at 50°C to fully dissolve phenols and sugars, then added ionic liquid, stirred and mixed evenly at 50°C, placed in a microwave oven with a power of 400w, heated for 600s, and the obtained material was water After washing with ethanol and drying, a high specific surface area bulk porous carbon material is obtained.

[0019] The phenols are formed by mixing phenol, resorcinol, and phloroglucinol at a mass ratio of 1:1:1; the sugars are formed by mixing fructose and cellulose at a mass ratio of 1:2; the ionic liquid is 1 -Ethyl-3-methylimidazole tetrafluoroborate, trimethylpropylammonium bistrifluoromethanesulfonimide salt and 1-hexyl-3-methylimidazole bistrifluoromethanesulfonimide salt by mass The ratio is 1:2:3 mixed.

Embodiment 3

[0021] A preparation method of high specific area bulk porous carbon, mixing according to the mass ratio of phenols: sugars: water: ionic liquid = 1: 2: 20: 0.3, first mixing phenols and sugars, and then adding Deionized water, and stir at 50°C to fully dissolve phenols and sugars, then add ionic liquid, stir and mix evenly at 50°C, place in a microwave oven with a power of 700w, heat for 450s, and the obtained material is water After washing with ethanol and drying, a high specific surface area bulk porous carbon material is obtained.

[0022] The phenol is resorcinol; the sugar is lactose; and the ionic liquid is N-methylbutylpiperidine bistrifluoromethanesulfonimide salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com