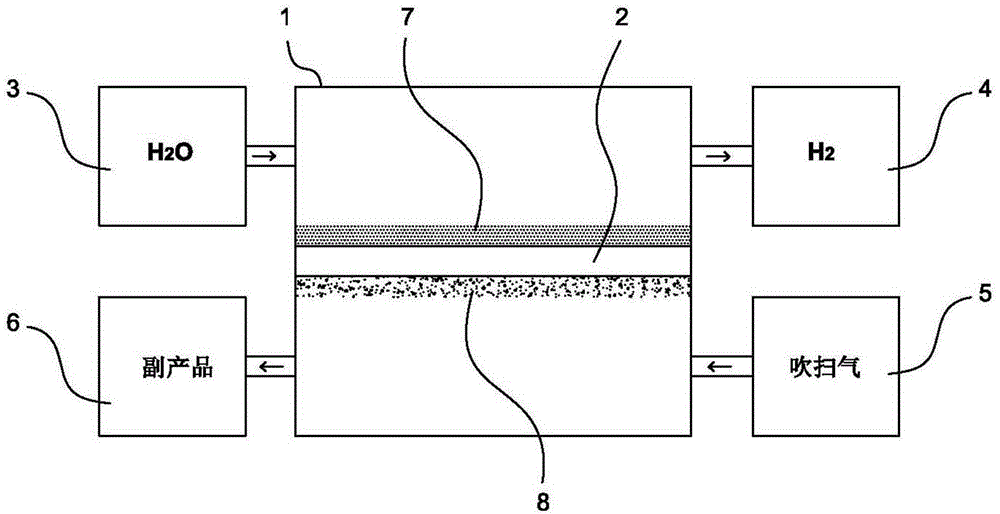

A system for preparing high-purity hydrogen and a method therefor

A high-purity, hydrogen technology, applied in hydrogen production and other directions, can solve the problems of hydrogen production cost and hydrogen production scale that cannot meet large-scale application, limited wide application, low stability of Pd resources and palladium membrane, etc., and achieve rich raw materials. , low-cost, easy-to-prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

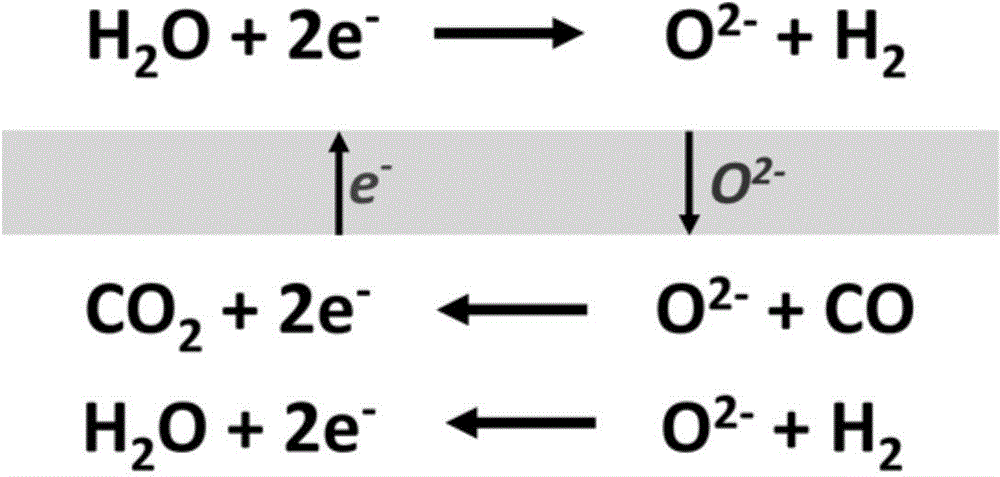

Method used

Image

Examples

Embodiment 1

[0067] The sintered dense oxygen-permeable film La 0.7 Sr 0.3 Cu 0.2 Fe 0.8 o 3-δ (Balachandran U, et al. La 0.7 Sr 0.3 Cu 0.2 Fe 0.8 o 3-δ asoxygentransportmembraneforproducinghydrogenviawatersplitting.ECSTrans2008; 13:393-403.) sanded to a thickness of 0.5mm and filled with Ru / Ce on both sides of the membrane 0.85 SM 0.15 o 1.925 (SDC) Catalyst, the membrane loaded with the catalyst was sealed in a membrane reactor at 961° C. with a silver ring. The effective area of the membrane is 1cm 2 . After slowly cooling down to 900°C, the flow rate of one side of the membrane is 50mLmin -1 H 2 O, the other side with a flow rate of 50mLmin -1 Syngas (n(H 2 ) / n(CO)=1) as purge gas.

[0068] The chromatographic detection results prove that within the detection limit of the chromatogram, only hydrogen exists, and the hydrogen purity is ≥ 5N. The hydrogen separation rate is 3.3mLcm -2 min -1 . After a 100-hour stability test, the hydrogen separation performance did ...

Embodiment 2

[0070] The sintered dense GDC-Ni dual-phase membrane (BalachandranU, etal.Useofmixedconductingmembranestoproducehydrogenbywaterdissociation.IntJHydrogenEnergy2004; 29:291-6) was polished to 0.2mm with sandpaper and filled with Ni / GDC catalyst on both sides of the membrane. Sealed in a membrane reactor at 961 °C. The effective area of the membrane is 1cm 2 . After slowly cooling down to 900°C, one side of the membrane was injected with 50mLmin -1 H 2 O, the other side with a flow rate of 50mLmin -1 Syngas (n(H 2 ) / n(CO)=2) as purge gas.

[0071] The chromatographic detection results prove that within the detection limit of the chromatogram, only hydrogen exists, and the hydrogen purity is ≥ 5N. The hydrogen separation rate is 4.8mLcm -2 min -1 . After a 100-hour stability test, the hydrogen separation performance did not attenuate.

Embodiment 3

[0073] The hollow fiber membrane Ce 0.8 SM 0.2 o 2-δ -La 0.7 Ca 0.3 CrO 3-δ (ChenCS, etal.PreparationandoxygenpermeabilityofCe 0.8 SM 0.2 o 2-δ -La 0.7 Ca 0.3 CrO 3-δ dual-phase composite hollow fibermembrane. Solid State Ionics2012; 225:690-694.) Ru / Ce is filled on both sides of the reactor 0.8 SM 0.2 o 1.9 Catalyst, the effective area of the membrane is 0.92cm 2 . After slowly cooling down to 800°C, one side of the membrane is fed with a flow rate of 80mLmin -1 H 2 O, the other side with a flow rate of 50mLmin -1 Syngas (n(H 2 ) / n(CO)=3) as purge gas.

[0074] The chromatographic detection results prove that within the detection limit of the chromatogram, only hydrogen exists, and the hydrogen purity is ≥ 5N. The hydrogen separation rate is 0.78mLcm -2 min -1 . After a 100-hour stability test, the hydrogen separation performance did not attenuate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com