Dry fog dust removing plant for car dumper shed zone

A kind of dust removal equipment and dry fog technology, applied in the field of dust removal, can solve problems such as difficult control, dust pollution, and large dust power, and achieve the effect of small weight ratio, strong dust removal ability, and small water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

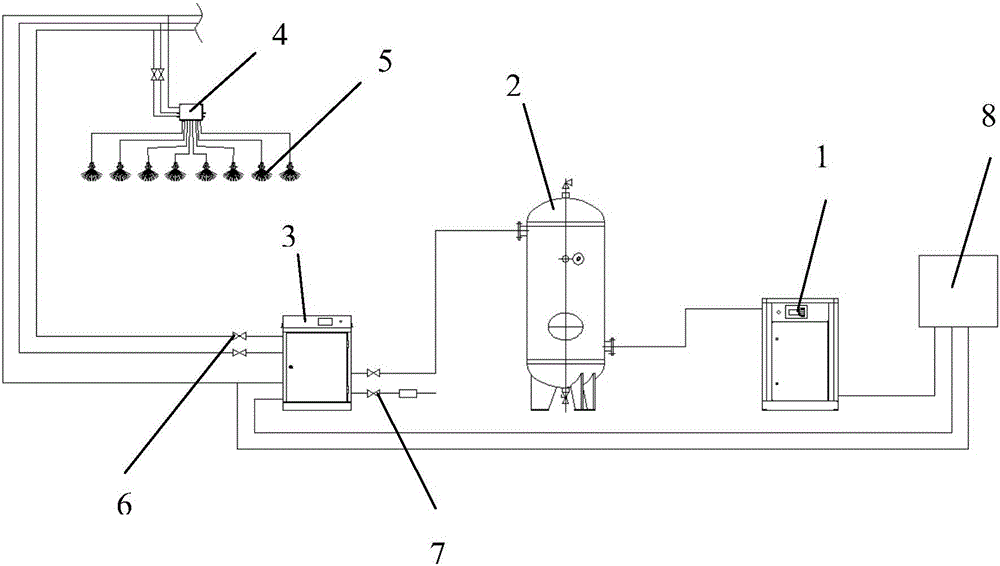

[0012] The present invention will be further described in detail through specific embodiments below. The dry fog and dust removal equipment in the dumper room area is characterized in that it includes an air compressor 1, an air storage tank 2, a dry fog machine 3, a water and gas distribution box 4, and a controller 8. The air compressor 1 is connected to the air storage tank 2 and the controller 8, the air storage tank 2 is connected to the dry fog machine 3, the dry fog machine 3 is connected to the controller 8, and the dry fog machine 3 is connected to the water vapor through the pipeline provided with the valve 6. The distribution box 4 is connected, a filter 7 is connected to one side of the dry fog machine 3, and a sprayer 5 is connected to the lower end of the water-gas distribution box 4, and a mixed liquid recovery device is provided below the sprayer 5 of the dry fog dust removal equipment in the tipping machine room area. The pipes of the dry fog and dust removal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com