Multilayer elastic windproof fabric and production method thereof

A production method and fabric technology, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of lack of natural fiber texture and touch, lack of elasticity, insufficient elasticity, etc., and achieve high-end appearance style , delicate touch, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

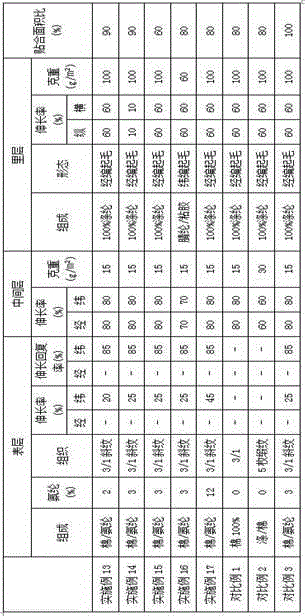

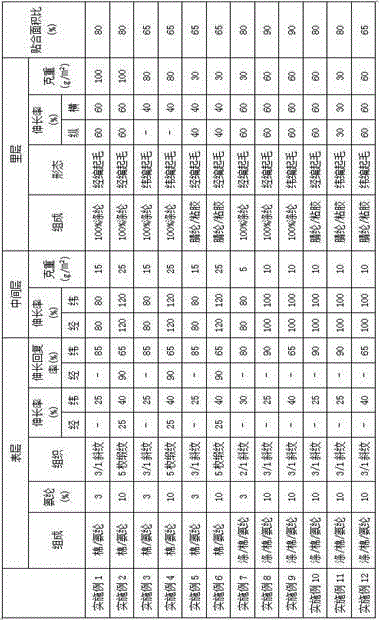

[0047] Surface layer: 3 / 1 twill weave, cotton / spandex weft elastic woven fabric with 3% spandex content, the weft elongation of the woven fabric is 25%, and the elongation recovery rate is 85%;

[0048] Middle layer: Polyurethane microporous film, the elongation in warp and weft direction is 80%, and the weight is 15g / ㎡;

[0049] Inner layer: 100% polyester raised warp knitted fabric, the vertical and horizontal elongation is 60%, and the weight is 100g / ㎡.

[0050] The surface layer and the middle layer are subjected to a lamination process → maturation process → a secondary lamination process → calendering process for the inner layer and the primary lamination product to obtain the windproof fabric of the present invention. The compositions and properties of the windproof fabric obtained are shown in Tables 1 and 3.

[0051] Among them, in the bonding project, the bonding method adopts discontinuous bonding, the bonding area ratio is 80%, and the concentration of the release...

Embodiment 2

[0053] Surface layer: 5 cotton / spandex four-way stretch woven fabrics with satin weave and 10% spandex content. 40%, elongation recovery rate is 65%;

[0054] Middle layer: Polyurethane microporous membrane, the elongation in warp and weft direction is 120%, and the weight is 25g / ㎡;

[0055] Inner layer: 100% polyester warp-knitted raised knitted fabric with 60% vertical and horizontal elongation and a grammage of 100g / ㎡.

[0056] The surface layer and the middle layer are subjected to a lamination process → ripening process → a secondary lamination process → calendering process for the inner layer and the primary lamination product to obtain the windproof fabric of the present invention. The compositions and properties of the windproof fabric obtained are shown in Tables 1 and 3.

[0057] Among them, in the lamination project, the lamination adopts discontinuous lamination, the lamination area ratio is 80%, and the concentration of the release agent resin used is 10g / L; the...

Embodiment 3

[0059] Surface layer and intermediate layer are with embodiment 1;

[0060] Inner layer: 100% polyester weft-knitted raised knitted fabric with a transverse elongation of 40% and a weight of 80g / ㎡.

[0061] The surface layer and the middle layer are subjected to a lamination process → maturation process → the inner layer and the primary lamination product are subjected to a secondary lamination process → calendering process to obtain a windproof fabric.

[0062] Wherein, in the bonding project, the bonding area ratio is 65%, and the rest are the same as in Example 2; the windproof fabric of the present invention is obtained. The compositions and properties of the windproof fabric obtained are shown in Tables 1 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com