Automatic cutting and grinding all-in-one machine

An all-in-one machine and automatic cutting device technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of energy waste, complex structure, cumbersome operation, etc., and achieve reduction of industrial pollution, simple transmission structure, and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

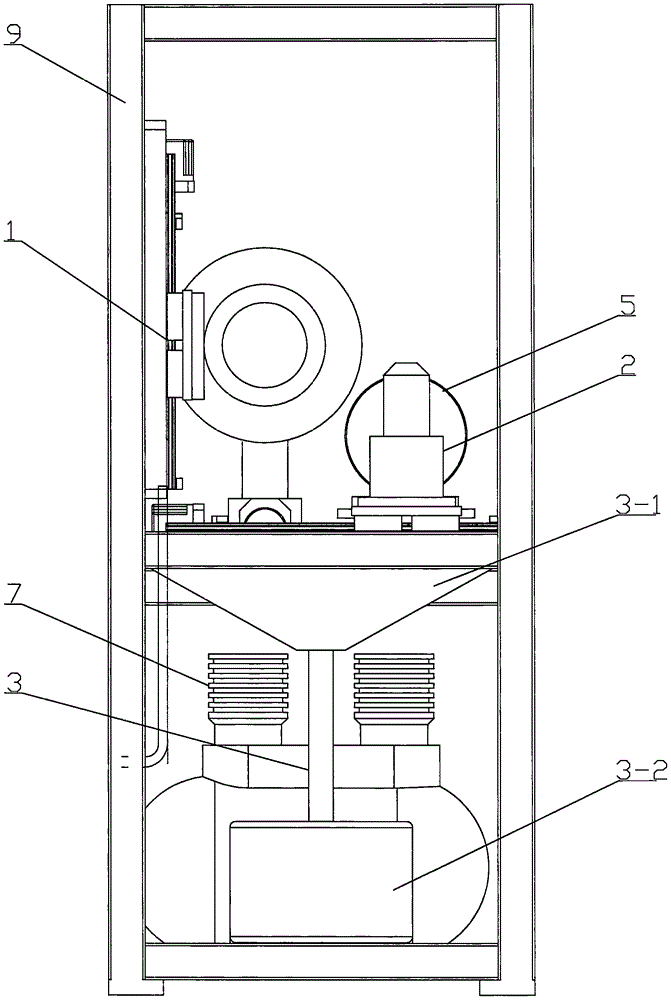

[0034] Such as Figures 1 to 4 As shown, the automatic cutting and grinding machine includes automatic cutting assembly 1, automatic clamping rod assembly 2, dust collection device 3, PLC control cabinet 4, automatic grinding assembly 5, cooling device, air cooling system 7, Solenoid valve 8, frame 9. Among them: the cooling device includes cutting and grinding continuous cooling nozzle 10 and continuous cooling nozzle 6, automatic cutting assembly 1 is composed of automatic cutting device and automatic cutting linear walking device, automatic clamping rod assembly 2 is composed of automatic clamping rod device and Automatic clamping linear walking device is formed, and automatic grinding assembly 5 is made up of automatic grinding device and automatic grinding linear walking device. Automatic cutting assembly 1, automatic clamping rod assembly 2, automatic grinding assembly 5, continuous cooling nozzle 6, cutting and grinding continuous cooling nozzle 10 are set on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com